Improving the 1/32 Revell kit

[ page 2 ]

... continued from page 1...

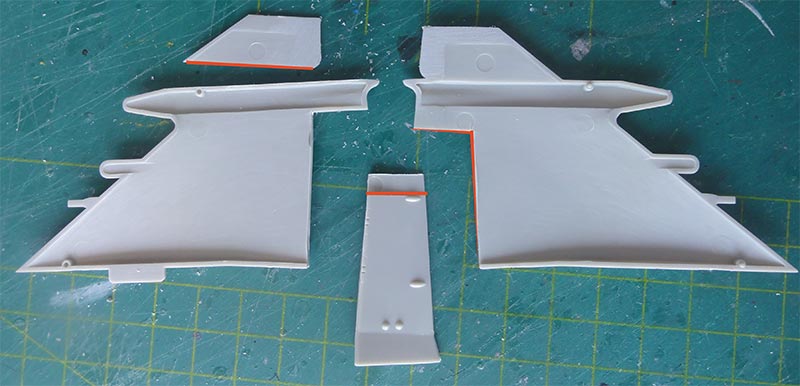

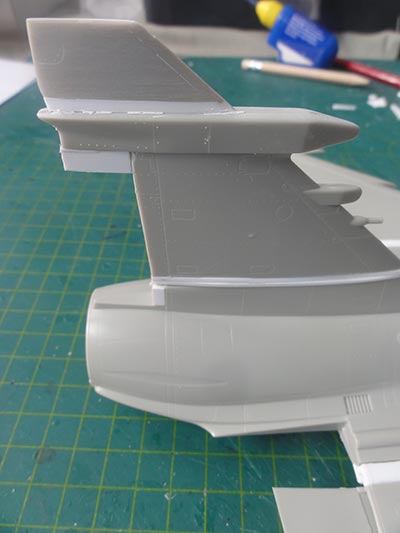

VERTICAL TAIL

This vertical tail itself needs corrections as well with an increase vertical tail height at the lower base by 3 mm and at fin top by about 2 mm (total increment = 5 mm);

With a razor saw, several cuts were thus made.

For the increased height, a few strips of card were used. The upper tail section will be a piece of card 2 mm and is seen here after puttying.

These root base of 2 x 1,5 mm thick = 3 mm card sections were set on the rear fuselage. The rudder will also be enlarged with card (the raised knobs on the kit part will be sanded off).

It was decided not to change the vertical tail fairings, though not 100% accurate but good enough.

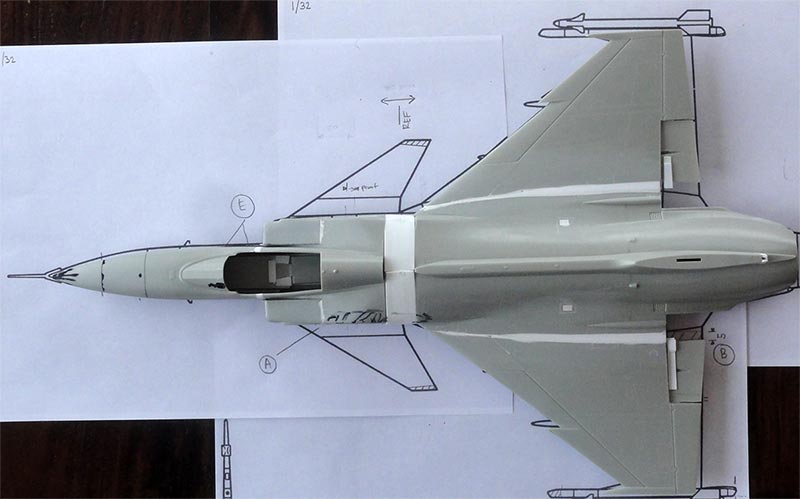

An important step is now to join the forward and rear fuselage-wing assembly. It was crucial to check symmetry and get enough strength with long strips of thick sprue. An exciting moment! (prepared vertical tail is also seen)

As seen below, the air funnel inside and extra strips were set between sections with spine and rear spine. Let dry for at least 24 hours.

MAIN GEAR BAYS

For the corrected main bay opening shapes, a piece of curved card insert was made to fit. This way, the main closed doors will be “virtually” lengthened 10 mm.

Also bits of card were needed to get more strength and all set with clamps to dry.

Making this curved card insert took quite some time. Note that the main closed doors are part of this insert.

Putty will be needed.

Card was installed at the upper spine....

A check was made with the drawing and it look OK. The spine insert here is 17 mm in 1/32.

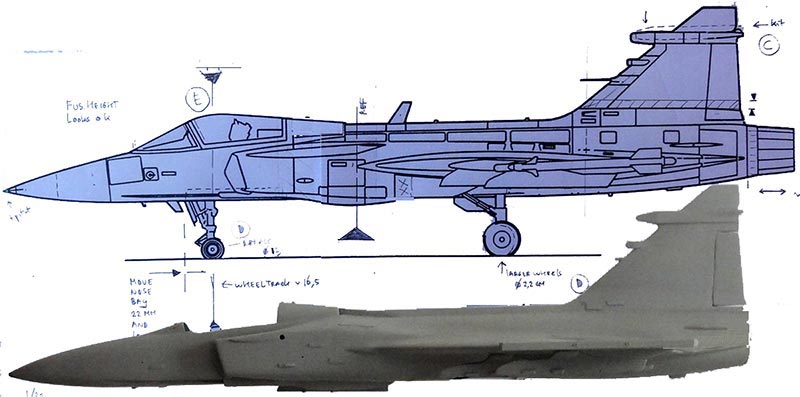

Now we have a 1/32 Gripen that is far more accurate in shape:

(1) increased fuselage lengths of 4+17 = 21 mm.

(2) with corrected wing span 2x 5 mm at the rear and the leading edge sweep looks much better now.

Note: at the ailerons, the sweep (about 1 degree) is not entirely accurate but it was decided not to mess with the thin trailing edges here.

Now a lot of putty and sanding is needed. But this will get a far better shaped model.

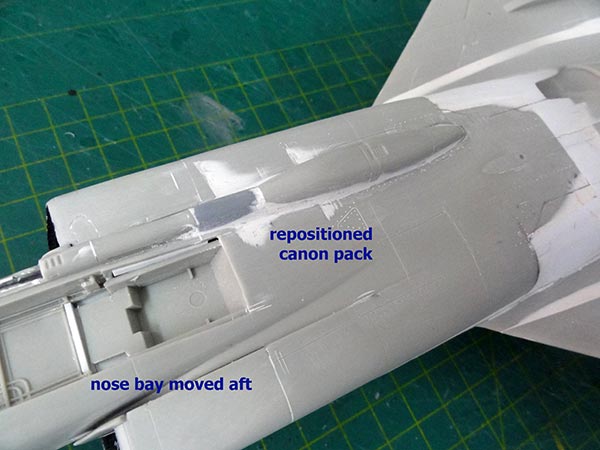

(photo here shows still the uncorrected gun fairing location)

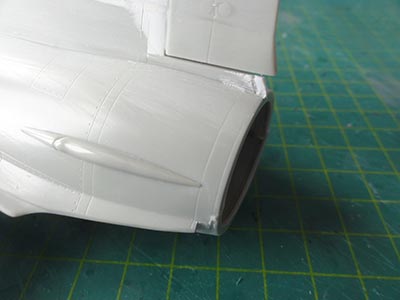

Each intake upper corner near the canard station should be a bit more curved. Sanding was done, be careful here as the plastic is thin. I had to make some repairs at the intake corner insides here as the plastic was very thin. The better result is seen here....

At the wing kink/ leading edge aft of the canard station it was found a small extension was needed as seen on real Gripens. It took quite some time to see this as it is missing in the original kit and is situated at the mid fuselage extension. (see drawing check above). The small extensions were made with a bit from the spares box, putty and sanding.

The spine exhaust aft of the cockpit took some work to get a perfect symmetrical result. Some putty still needed!

page 1

page 2

page 3

GUN FAIRING AND INBOARD FLAPS

I found a bit too late that the lower gun fairing needs to be lengthened in the middle by about 12 mm and relocated as well. So the kit shape was cut off horizontally with a razor saw.

It can be done.

Some card was set and close the big gap. A 12 mm section was set in the middle and putty and sanding needed again!

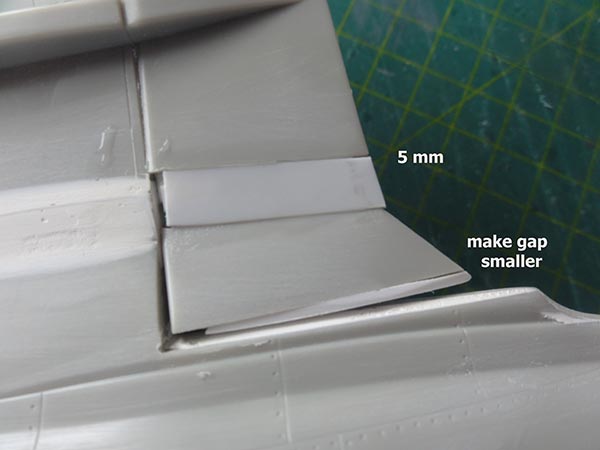

FLAPS

The inboard flaps are still separate parts. They will also be used to suggest a slightly better trailing edge angle as I had to rotate a bit the wing planform. Measuring and dry fitting was done now. The gaps between flap and fuselage will be kept but not too wide using card and putty. The ailerons will be unmodified.

Pieces of card (5 mm width again) are needed.... and again putty!

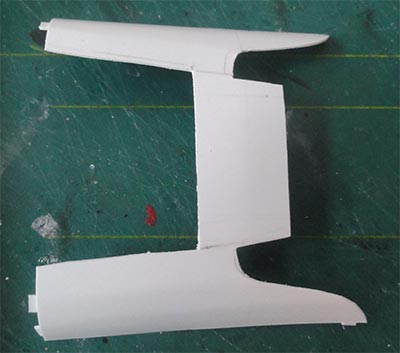

VERTICAL TAIL

The corrected vertical tail was set onto the rear fuselage. Ensure a vertical sit! Putty was needed

A small correction was also needed at the lower base as seen here.....

Here the overall result is seen of the kit corrections till now.

The model still needs some small putty clean ups and than a first grey base primer. Than a photo check will be made with the camera.

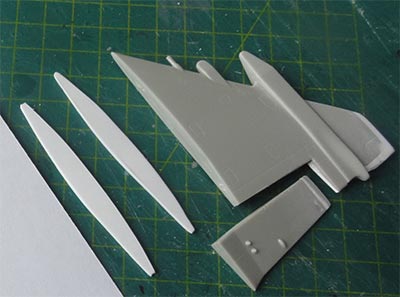

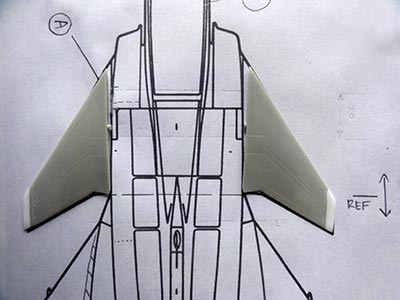

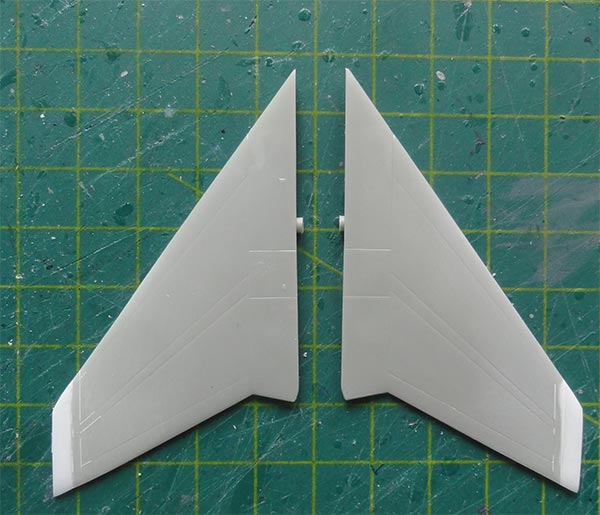

CANARDS

The shape of the canards is a good basis for further corrections. First remove the raised “stubs” and raised details.

Next, add a small tip extension of 3 mm with card. The small locks at their rotation rod were removed so it can be installed later on.

This is seen here compared with the drawing.

The canards were not yet installed at this stage as they are very vulnerable.

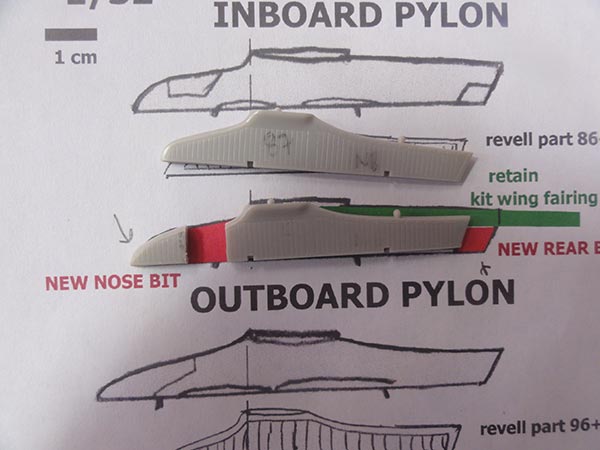

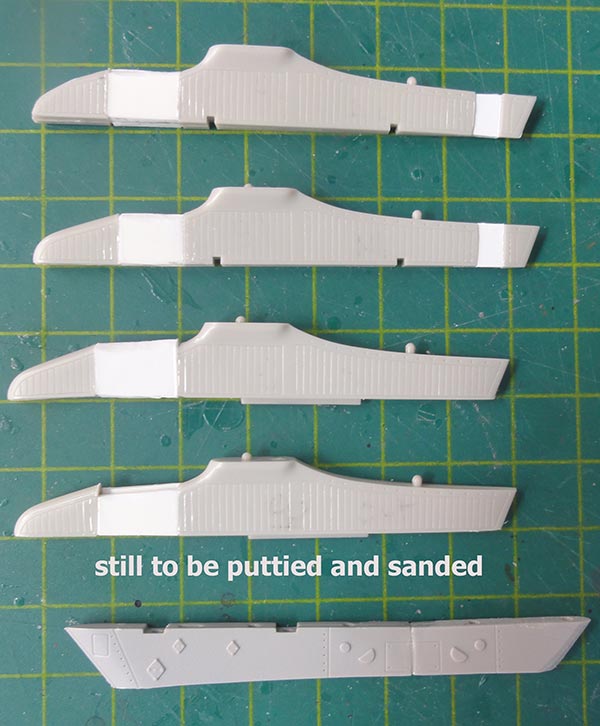

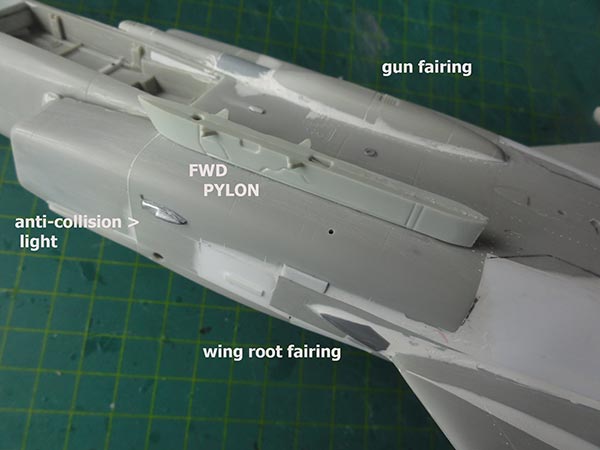

PYLONS AND STORES

Now the base model could be further completed but it would be nice to have also some pylons and stores. It is a good idea to tackle this now as it may need adjustments at the lower wing.

With various drawings and the good 1/72 Revell Gripen kit, it was found that the 1/32 kit pylons are very inaccurate.

A drawing was made to 1/32 and it was clear that when making inserts, sections of the kit pylons can be used. Cuts were made and putty and card used. The strange engraved vertical lines were also filled with putty and all was sanded.

A replacement for the central pylon was found in the spares box and will be adapted.

For the central fuel tank, it was also seen that it needs a flat horizontal cross section that is not in the kit parts.

An insert was made with strip of 4 mm wide, it was bended, glued, puttied and sanded.

The far better looking corrected central fuel tank and pylon is seen here.

For the wing tip missile rails that had been cut off earlier, some far better ones were found in the spares box and only needed a bit adaption.

It was also decided to add an extra forward pylon below the right intake. A good one was found in the spares box and a bit adapted.

FIRST OVERALL RESULT

It look fine till now.

A small fairing for the anti-collision light on each intake was added (the kit parts #34 were not used).

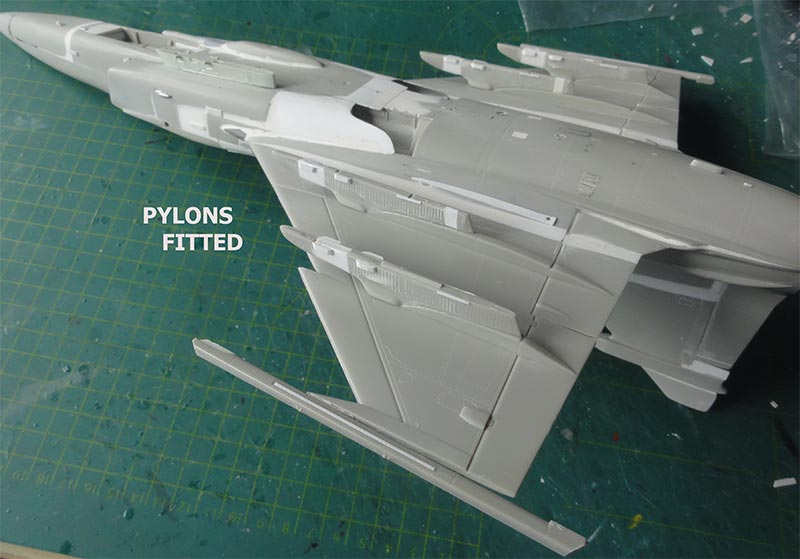

Also 4 re-shaped pylons were installed after the spanwise stations were checked with the 1/72 Revell kit. Any gaps with the wing were closed with putty but it took less effort than first thought. Note that the sweep angles of the pylon bases moulded on the wing were not changed, this is almost invisible, the pylons themselves were set "in flow direction".

Please note the replaced wing tip missile launchers.

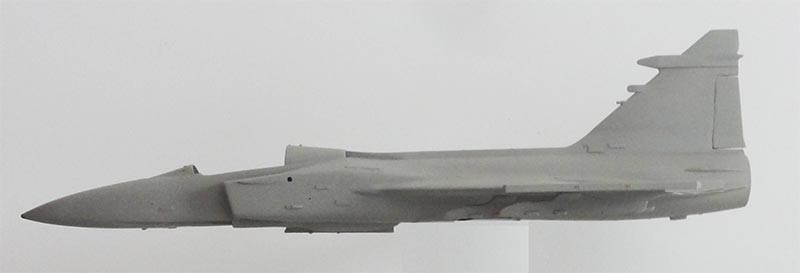

Please note the replaced wing tip missile launchers.An important build mile stone was reached! The overall model could now get a base grey primer coat.

I airbrushed Revell Aqua acrylic 75 “steingrau”.

An important stage to see any flaws in the puttied areas.

It was obvious that after so much modifications and puttying some small rework was needed with putty but nothing too dramatic. Some re-puttying and sanding was needed but took quite some effort to get smooth surfaces.

It was again checked with another pass of base primer.

The cockpit area obviously needs extra detail, to be done later. Also, an attachment point for the canards should be made. In the photo also on the intake the small fixed fairing at the canard is seen.

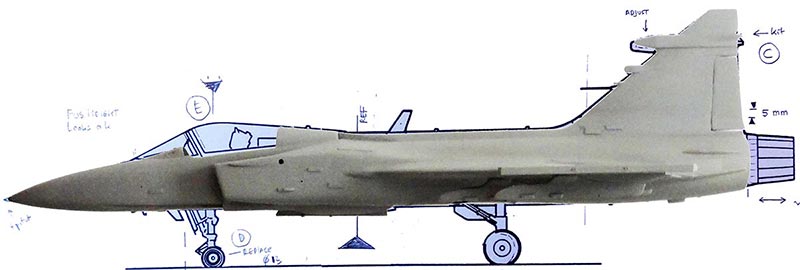

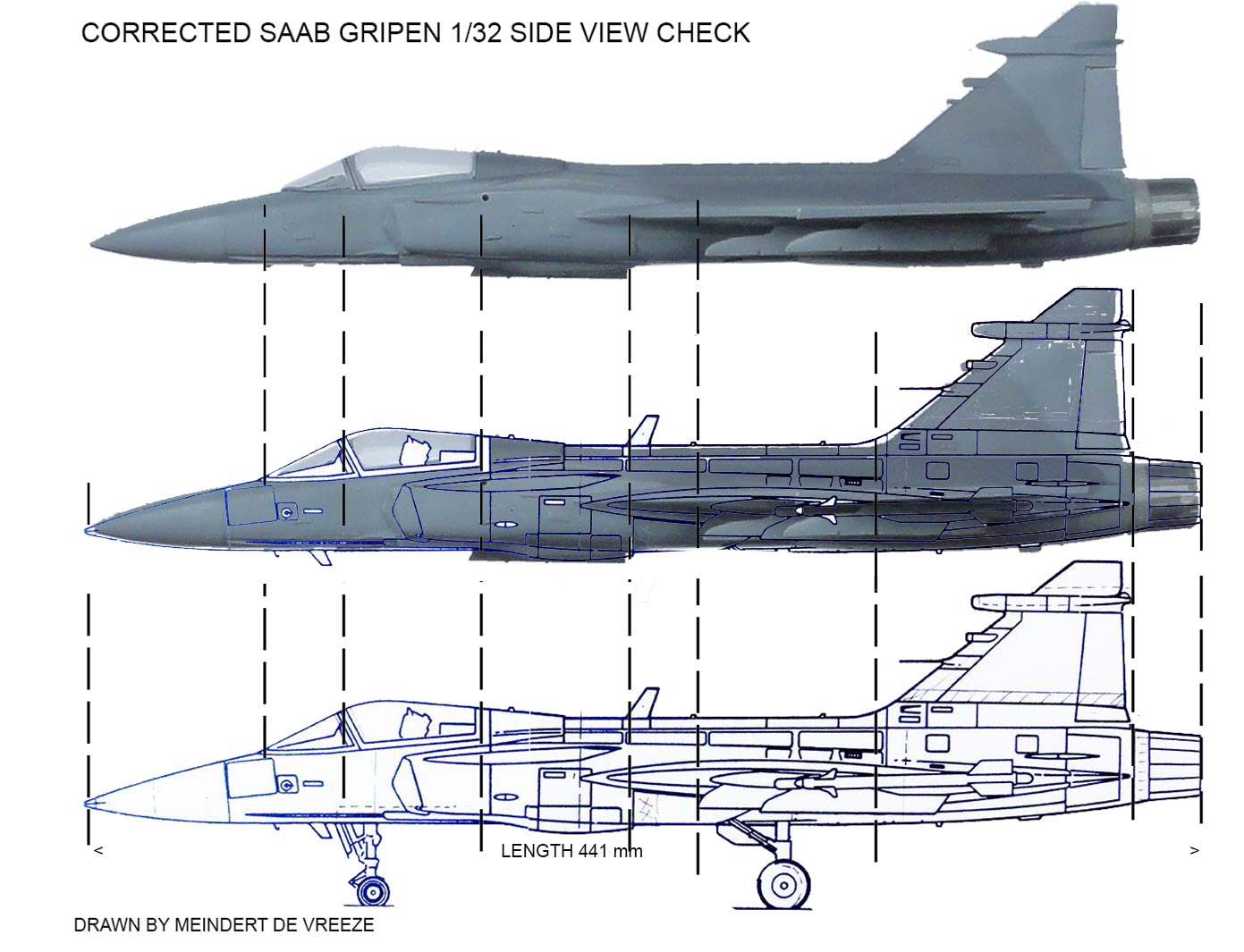

Another check was made with the photo camera with the scale drawing. A few photos were made "from a far distance to avoid camera lens distortion as much as possible".

The composition is seen here.

... and superimposed on the scale drawing....

... and superimposed on the scale drawing....

Some work is still be done with the windshield and removing 1 mm on top of the fin. The intake is now about 1,5 mm bit too far forward but will be retained as the canopy will be extended and will be set in open position....

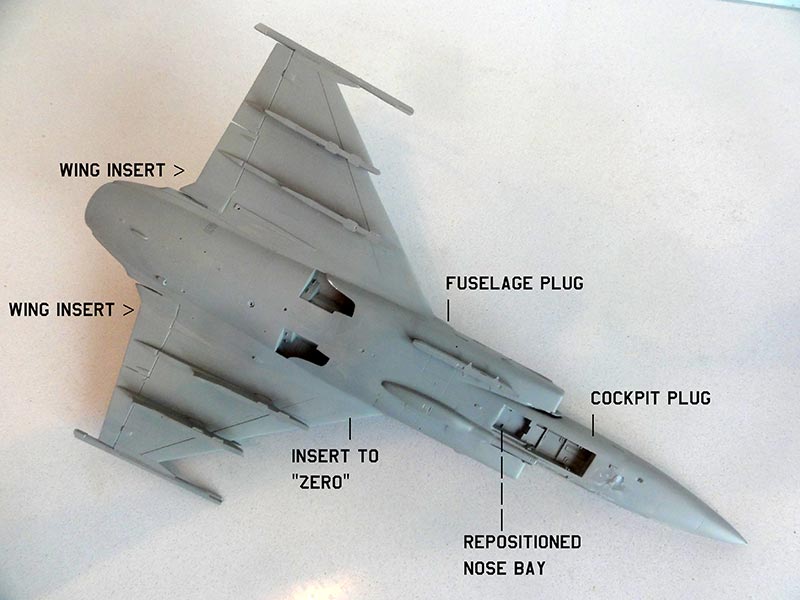

A summary of what has been done till now:

- fuselage plug of 17 mm

- cockpit plug / sill of 4 mm

- wing span from 5 mm each near flap to near 1 mm at forward edge with "vortex" extension

- new missile rails

- repositioned nose bay

- adapted main gear closed doors and bay

- improved gun fairing

- improved pylons

- improved vertical tail

- (canards are here not yet installed)

Still, some minor corrections will follow as well as the smaller details to be added like large fences on fuselage near canards, low visibility light strips etc etc (not yet done)

From the corrected vertical tail, 1 mm was sanded off from the top. After these changes, the intakes sit about 1,5 mm too much forward; it was decided not to change this. The (to be improved) canopy will be set open and than it is not too obvious.

The next important mile stone is going forward with the colour scheme…

PANELS AND COLOUR SCHEME

The model got a few recessed panellines with the OLFA panel scriber. But I did not add many as large areas are puttied and not to spoil the surface appearance. A lot can be done also with pencilled lines and shading.

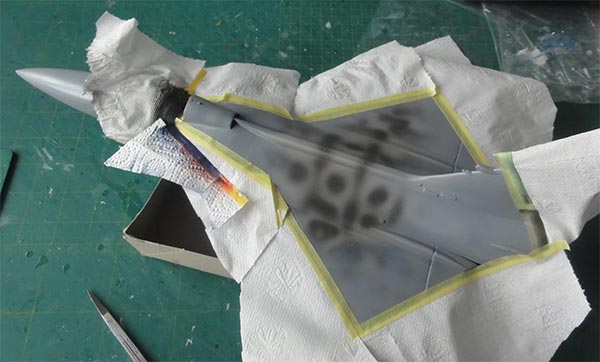

As seen, a few base “weathering” effects with black patterns were airbrushed for any recessed panel lines.

Now what scheme and air force to pick?

My long time modelling friend Erwin Stam persuaded me to make this model in a South Africa Air Force (SAAF) scheme and provided some photos and info also from South African friends.

South African Gripen provided and photographed by Erwin Stam (c).

Though this model would need some custom made decals with low visibility SAAF markings and flag, it can be done with some decal design work.

According to wikipedia: The SAAF accepted its first Gripen D two seater in April 2008 and the final two Gripen D aircraft arrived in South Africa in July 2009. The first two Gripen C single seat fighters arrived February 2010 with deliveries ongoing to October 2011. The no. 2 squadron based at Makhado AFB near the town of Louis Trichardt in the North of South Africa operates all the SAAF's Gripens except for the first Gripen D, which is assigned to the Test Flight and Development Centre at AFB Overberg.

Photos were studied. SAAF Gripen JAS39C tail code “12” cn 39-2103 coded 3912 of no. 2 squadron was picked.

I designed the decals with a graphics program on the PC and the decals than will be custom laser printed by a friend on decalpaper. More about that later on.

The SAAF Gripen camouflage scheme shows a sort of “diamond shaped pattern”. Apparently, the specified colours and scheme when the Gripens were ordered were not followed by SAAB for unclear reasons.

South African Gripen provided and photographed by Erwin Stam (c).

It seems that the actual colours of the SAAF Gripens are approx. an overall scheme of Fed.Std FS36320 grey and the diamond in FS36118.

Gunze Sangyo acrylic colours were airbrushed of respectively H307 and H305 but any paint brand will do for these Federal Standard colours.

Some “soft masking” is needed with now the diamond seen..

The gear bays and door insides are mainly white.

MAIN CANOPY

As the cockpit sill had been increased 4 mm in length, so the canopy should be increased in length, the proportions will than also look like seen on the real Gripen.

The approach chosen was to shave off any raised kit canopy details. Frames of 2 mm each at the rear and front edges will be added from bended card strips.

First the canopy was, after masking the main areas, carefully sanded at the raised edges so the raised frames are now removed/ hidden and than polish A LOT!

The needed canopy extension of frames of 2x 2 mm width: at front and rear edges were made with bended plastic strip.

The interior of the canopy framing was made from scrap with card looking at photos. This canopy is turned open to the left, there is a strength bar aft of the seat. Also, I saw rather wide edges at the canopy front with the mirrors almost being unvisible when seen from the front. The mirrors were cut from metal sheet.

Detailing the canopy requires care as not to damage the clear section. Main frame colours are black.

IMPORTANT NOTE: a central thin frame is not yet set, it will be added later onto the canopy top centre line; also, the cross bar had to be repositioned more to the rear; to be seen later.

WINDSCREEN

The windscreen was the next item. It was placed in position but it did not look good. It seemed that the steep angle was a bit too much. To make sure, another overall model side view photo was made from long distance to avoid camera lense distortion. With the photo editor program it superimposed on the scale drawing.

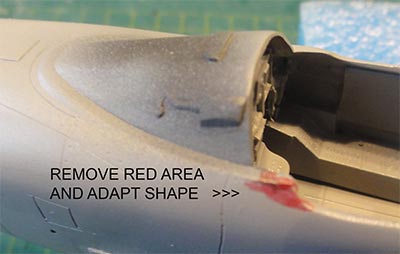

I concluded that the windscreen should still be set about 2 mm more forward and tilted a bit to get a less steep angle…

This can be achieved in 2 steps: first by removing some plastic at the rear area of the windscreen mating surface; this is marked here “red”:

Sand symmetrical. Next, I added a strip of 1 mm below the front of the wind screen nose at the mating surface. There will than be a visible gap but this can be closed/ filled with putty. The other small gap between the windscreen rear edge and front of canopy is not obvious as the canopy will be set open on the model. To be done.....

PHOTO CHECKS

A new side view photo with corrected wind screen sit (again from long distance to avoid camera lense distortion) was made and another check including the "line patterns" as seen here:

The side profile looks fine though the intake looks to be about 1 mm bit too far forward but this is almost undetectable.

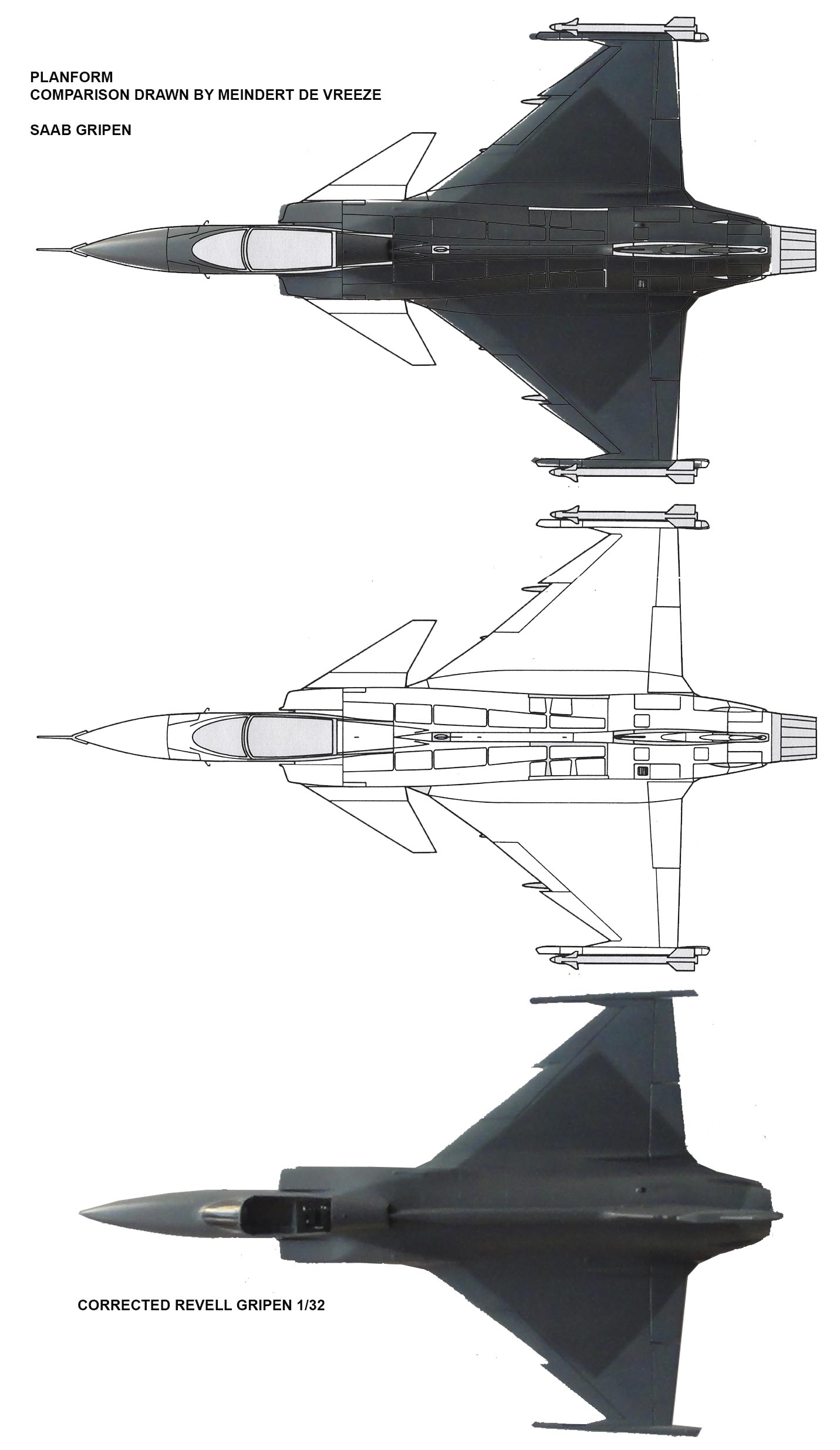

An upper view photo was made from a large distance to do a check.

In upper plan view the model looks quite good. The span is correct with a better leading edge sweep. The trailing edge angle and wing chord at the ailerons deviate as expected a bit as the wing planform was rotated but this is not obvious when looking at the model. The nose upper profile with canopy and wind screen looks good now.

As regarding the intakes they look OK though the angled upper is a bit different than the drawing, but may be here the drawing is not entirely correct. It was concluded this issue is almost indetectable. Also the canopy will be set in open position.

After all that effort done on correcting the Revell kit I was happy! Ready to proceed further on detailing.

Back to 1/32 models.......

(c) Copyright "designer"/ All rights reserved. Your comments are welcomed by webmaster

Created

Dec 9 , 2021