Royal Netherlands Air Force "Kaasjager"

[ page 3 ]

F-86K (called Kaasjager in Dutch) Sabre in 1/32 scale

... back to F-86K page 2....

The AEROPOXY

F-86K model will be finished as a "later" F-86K

Kaasjager of the Royal Netherlands Air Force

that got RETROFITTED beginning nineteen sixties with a "F-40 Sabre type"

wing. This F-40 wing has a larger chord and extended wingtip and again

is fitted with slats. It is recognizable as it has a straight pitot tube.

Of the HASEGAWA F-86F the wing (part #C1) is perfect and the also other

parts of such a Hasegawa F-86F kit JS-084 will be used.

AGAIN AN

UPDATE: Kitty Hawk released an injection

F-86K kit 3rd quarter 2015.

It was decided

to continue modelling the AEROPOXY 1/32 resin conversion, otherwise it will

end its life at the rear bottom shelf of the model kits stash forever....

Handling resin parts may be harmful, so read my resin handling tips here...

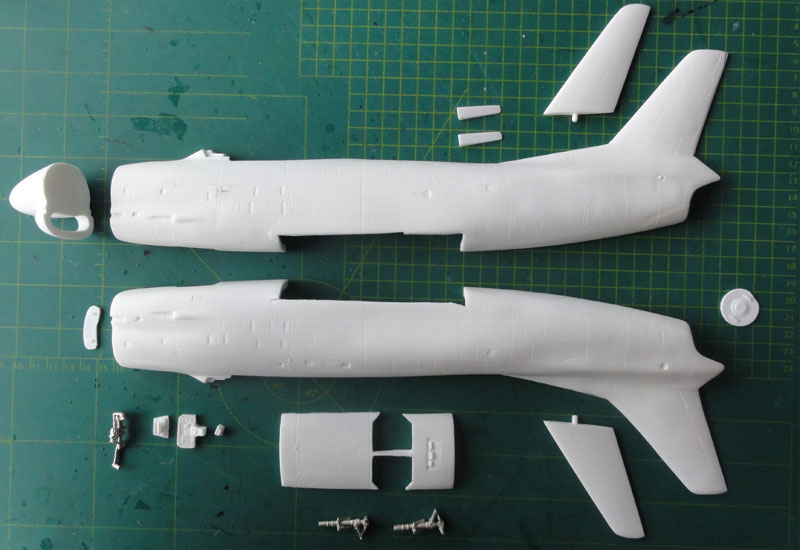

The resin parts

are thick and of very hard resin. Walls are thick as well.

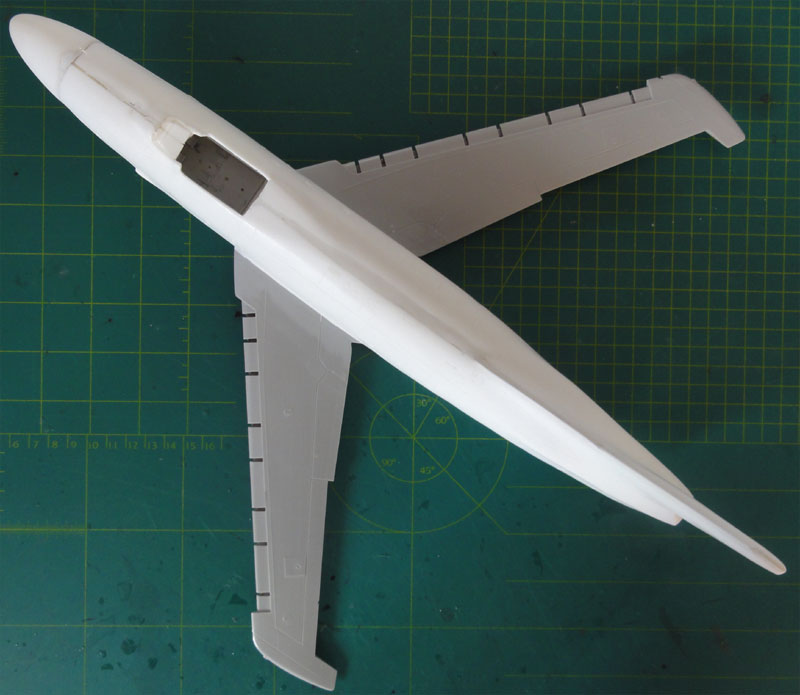

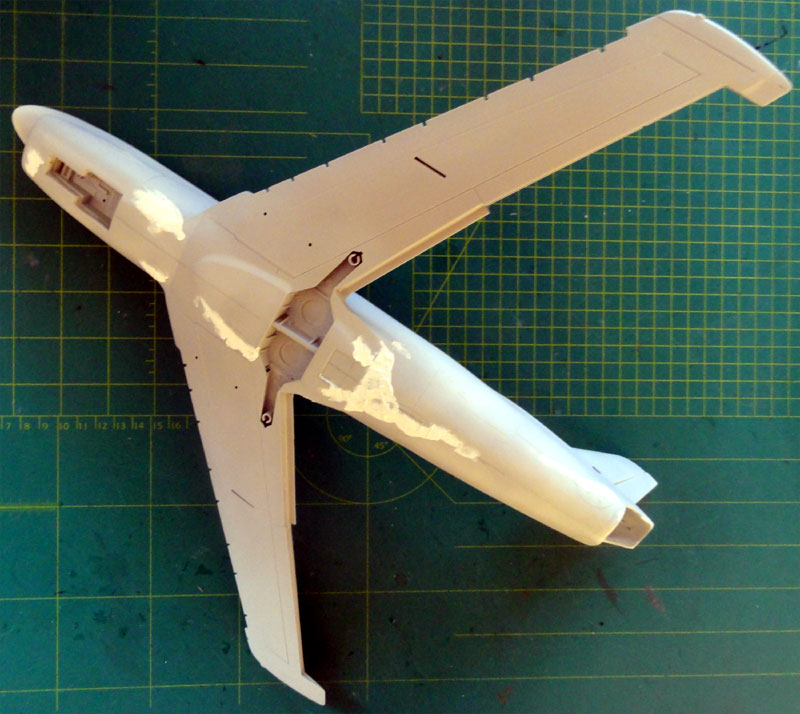

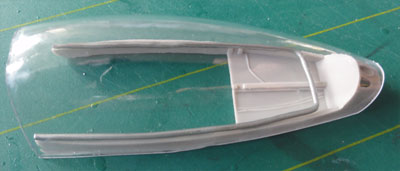

The main parts

are seen here and the vertical tail is rather thick.

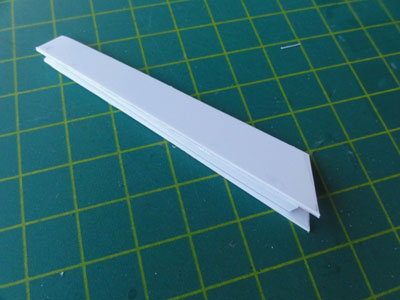

It was decided

to remove the rudder and to refine the leading edge of the tailfin. So,

a new rudder was made of plastic card and ot a nice thin trailing edge.

.......

....... .....

.....

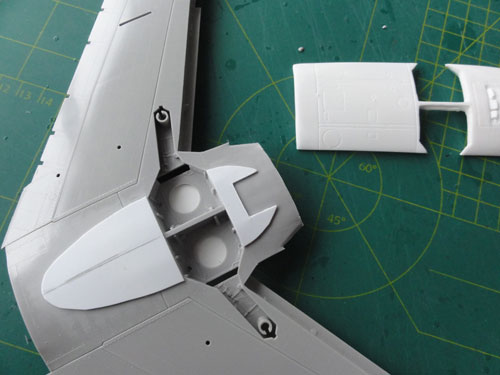

There is a

large gap at the lower wing position in the fuselage so I could fit inside

a cockpit tub later on. It was also decided not to make an air tunnel inside,

covers will be set in place and these are provided in the AEROPOXY set.

So the large fuselage halves and nose could be set together. Two component

Epoxy BISON KOMBI glue with a harder was used and this gives strong

joints.

The nose fits

not too bad either. With clamps all components were fixed and let to dry

24 hours.

The pretty large

gaps were filled with white car filler (Dutch brand "Alabastine Autoplamuur")

and when dried up, sanded and smoothened. This required some repeatment

to get a good first result.

The leading

edge of the vertical tail got a strip glued on and lots of putty applied.

This was sanded to get a sharp result with a much better appearance. The

tailplane holes were also drilled out.

The lower AEROPOXY

wing root plate was not used.

F-86K aircraft

often later during their career got a wing modification with the larger

"F-40" wing. These also could fire Sidewinder missiles. So this model was

made as later F-86K and got the one piece HASEGAWA F-86F "F-40" wing.

As compared

to the F-86D Sabredog the F-86K has a slightly thicker belly, so a piece

of card was set in place and the edges will be puttied. At the rear some

some exhaust and details are seen. These will be added as well. The holes

in the main gear bays were closed with card as well.

.

.

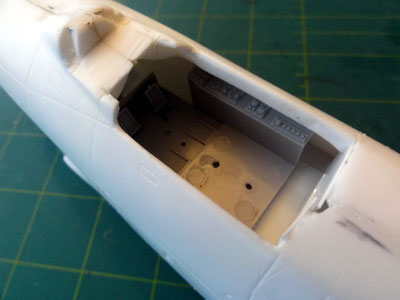

Inside the fuselage simply the cockpit

tub #D21 of the Hasegawa kit was set in place. Detailling can be done later

through the cockpit opening. A simple rear bulkhead was made from plastic

card to close the gap.

After that,

the wing could be set in place.

The grey wing

(Part #C1) of the Hasegawa kit is seen here with the "belly" add on.

The gaps between the fuselage and wing needed loads of card and filler

to close the gaps and sanded to get smooth results.

The result

is seen here and some refilling and sanding is needed.

The upper wing

root junctions also need some filling. Nice is that the Hasegawa kit have

separate slats and flaps and on a real Sabre these droop down when an aircraft

is parked at the tarmac.

.

.

NOTE: the wing is bigger as

the trailing edge flaps and ailerons are not seen below...

The assembly

got a first coat of light grey base paint to check for any areas that need

more filling and sanding. Any base coat will do, I used Revell Aqua 371

"Hellgrau" acrylic paint applied with the airbrush.

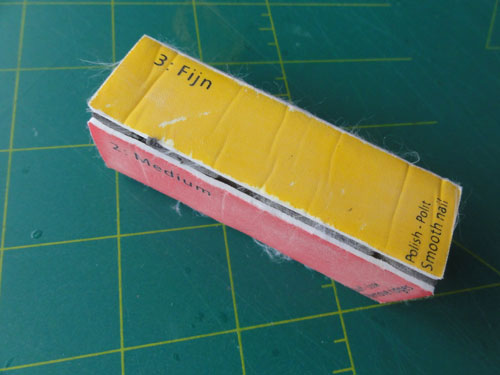

Some areas

needed again some filler and sanding. I used a polishing block to remove

any scratches as well. And another grey coat was airbrushed....

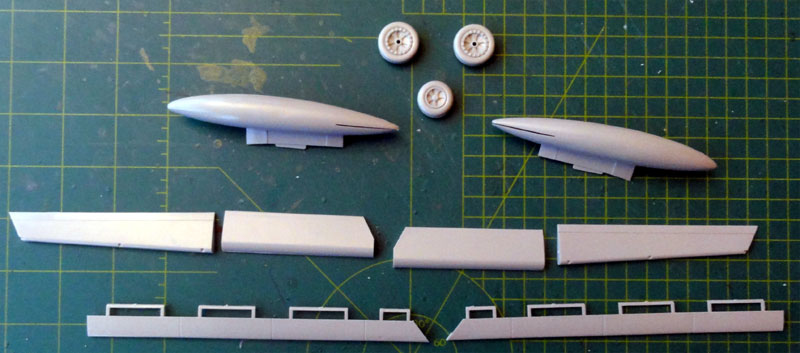

Various other

parts needed were retrieved from the Hasegawa kit, like the slats, flaps,

smaller wing tanks, wheel doors and so on.

The large horizontal tailplanes are in the AEROPOXY set and these needed filler to clear the small resin holes. (not seen here)

The F-86D and F-86K have an upwards tilting "clamshell type" cockpit canopy.

As expected the canopy on a short

run kit is always a challenge. Here a comparison is seen of three sets:

Hasegawa F-86F, TIGGER F-86D vacuform and AEROPOXY F-86K thin vacu.

(note: the Hasegawa F-86F canopy

and windscreen have an different smaller shape as on early Sabres and are

not further of use here; probably I will use it on the KINETIC F-86E kit

as its canopy looks a bit odd..).

The AEROPOXY canopy is very thin and

a bit flumsy. The TIGGER F-86D canopy is good to use but the AEROPOXY windscreen

looks better. And it was decided to used the base part #A6 of the Hasegawa

kit as a reference. This was also confirmed by drawings I had. The canopy

width of the TIGGER canopy has to be kept restrained, so a metal strip

was superglued on top to strengthen the base part and keep it in shape.

The vacu canopy will be glued outside the frame on the edges.

So for this F-86K, the canopy itself

is a combination of the TIGGER models vacuform F-86D rear canopy and the

AEROPOXY windscreen.

First, the internal details will

be painted and the outside of the canopy masked off. Final painting will

be done later.

Back to the

fuselage. Seen here is a small fairing at the rear and this was cut off

the TIGGER canopy.

..

..

After painting the lower instrument

base coaming, the AEROPOXY windscreen was set in place. Putty was needed.

Carefully mask the clear areas!

Again, some

base grey coat was applied. It seemed OK now.

The model was be given a natural metal finish of the Royal Netherlands Air Force "Kaasjager" F-86K, and several sheens are seen.

The ALCLAD II metal system will be used that requires a GLOSS BLACK undercoat so the model surfaces really need to be smooth.

(1) For the

undercoat Revell Aqua "Schwartz 07" acrylic Gloss Black was airbrushed

, thinned 40% with the Revell Aqua Color Mix thinner and 10% alkohol. Airbush

pressure was set at 1,1 PSI.

Ensure the

paint is really gloss. The other parts, like slats, flaps etc were not

forgotten.

..

..

(2) When dry,

some panels were masked with low tack tape (from Tesa). This to get very

simply some different sheens, see below how...

Also the big

black radar nose was masked off.

(3) ALCLAD

II ALC-105 Polished Aluminium was airbrushed. No thinning is needed

but were gloves and a face mask and plenty of ventilation! This ALCLAD

stuff is not good for your health.

(4) At mid way

airbrushing, the low tack tapes were removed. These areas now also got

the ALCLAD coat. This gives a different "panel" effect as the paint is

less thick.

and the result....

(5) After 24

hrs drying, some additional panels were masked with the low tack tape.

Particularly the large center wing panels have a different colour. This

was airbrushed ALCLAD II ALC-119 Airframe Aluminium. The areas at the exhaust

were given a coat of ALCLAD II ALC-113 Exhaust.

(6) Now the

green anti glare panel was , after masking, airbrushed olive green Revell

Aqua 361 "Olivgrun".

...

...

(7) The main

gear wheel bays and nose gear bay got a coat of Interior Green using WHITE

ENSIGN MODELS ACUS09 "interior green" enamel with the airbrush. Masking

was done with transparant food conservation foil and tape.

(8) The model

now had all main coats applied. Some small panels were painted light grey

at the vertical tail tip.

Back to 1/32 Models

(c) Copyright "designer"/ All rights reserved. Your comments are welcomed by webmaster

Created this page

Sept 18, 2013;

UPDATED October 15, 2015