[ page 2 ]

Soviet BlackJack bomber in 1/72 scale making the AModel Tupolev Tu-160

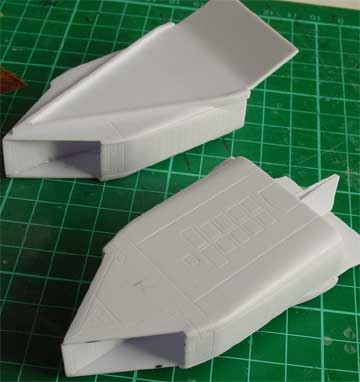

Engine fairings

Next Steps 9-12; Step 15, 18 ;

The engines are in two fairings below

the wing gloves. You have to open up first the intakes in step 7. The white

parts need some cleaning and sanding. The engine fan after some cutting

can be set into position from the rear of the fairings. (Paint the fans

now as they are unreachable later on).

The rear edge of parts #105+108 were

bended downwards and this will give a nice view to the engine fans.

The engine fairings take a lot of

work, but they have to correct size. Make sure not to mix up parts here.

Sand smooth and use putty here.

A piece of plastic card was blended in (as part #130 was not used) in the lower area. Also assure a good fit with the forward area with nose wheel bay.

The major problem is to get the

forwards engine sections to fit onto the rear fuselage sections.

You need a smooth fit with lots of

putty and sanding. It takes several putty coats to get a good end result.

Now, fitting the forward engine fairing

section to the rear is next....

Note the white card in the slot at

the engine fan positions, as the slot was NOT cut open in step 7. Fill...

and fil....

Again, on the lower areas, you need

a lot of work to get engines to fit!

some work

still needed... as seen below

Fill... sand.... fill... sand....

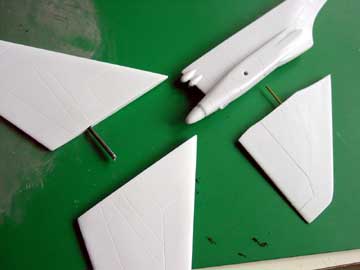

Rear empenage

Step 21-22

The stabilizers and moving upper

tail connecting rods were replaced by metal rods for strength. The base

fairing 65+66 was put onto the rear fuselage and required with the rear

part #64 and forward edge some filling. The moving surfaces will be fitted

AFTER painting.

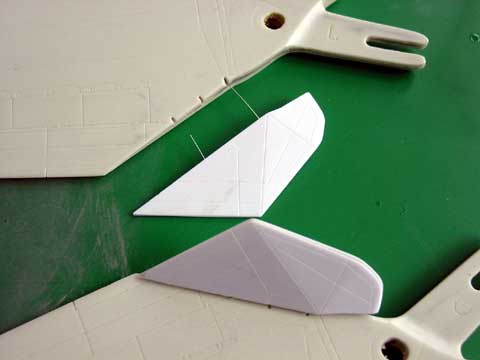

Wing gloves

Step 23-24

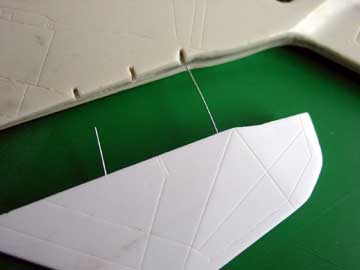

The swivelling wings have rotating

surfaces to close gaps (parts 122+123). This are simply rotated to get

a simpler mechanism by Tupolev. I decided to make the parts rotatable by

using very thin but flexible metal wire. These wires, 2 for each panel,

were set into tiny drilled holes.

..

The wing glove fairings (parts 125+126) were also set in place and needed some filling with putty to get a good result.

The wing rotating points will be made

from thick metal pins, replacing parts 145-146.

Wings are to be set in place AFTER

painting.

Gears and wheels

The legs of main undercarriage come

in different small parts and are NOT string enough. I simply added metal

rods on the sides and blended this in with white glue. As the main gear

is hidden by large doors and the engine pods, not a lot of it will be seen.

Also, I drilled larger holes to receive metal pins for getting a good strong

joint with the main fuselage section. The Tu-160 model is very large and

heavy and really you need to do this!

The Model is very heavy and will not stand on its nose gear. Adding weight in its nose will make it very very vulnerable. I decided to utilize a "pogo stick". This will keep the model horizontal.

Step 5 with nose glazing and nose gear, Step 16 + 19 main gear;

On to next

[page

3]...

(c) Copyright Meindert "designer"/ All rights reserved. Your comments are welcomed by webmaster

Created this page : April 11, 2005