1/32 vac / scratch

[ Page 2 ]

1/32 scale vacuform: ID Models (Tigger) SAAB J29 Tunnan

.. continued from page 1....

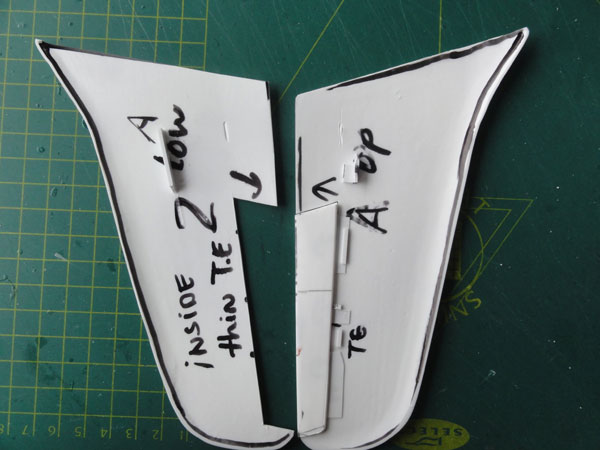

The wing plastic was sanded and cut out earlier. Inside, it required strength, so I added thick pieces of card inside. Make sure the thin airfoil shape is not compromised however. Note that this is a straight leading edge wing, so for an early J29 Tunnan like the J29A.

The wing halves got seperated ailerons, this looks beter at large 1/32 scale. The ailerons were separated from each wing part, so 4 parts for the lower and upper and left and right. Make sure to mark the seperate parts in order not to mix them up.

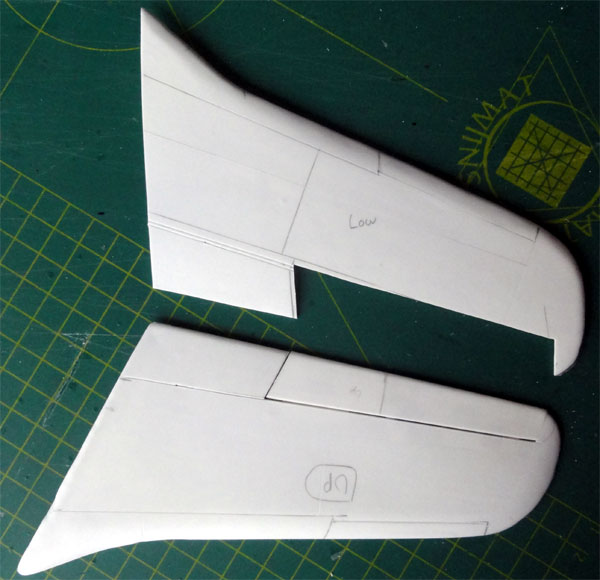

At this stage I also inscribed most of the recessed panellines. This is better done before joining the parts as pressure during scribing is needed. First pencil in where these lines are using the drawings. Next inscribe with a scriber, in this case an Olfa P-cutter using a flexible rod. The trailing edge flap edges were inscribed thicker and also the leading edge outboard slat (for the earlier J29 versions) were inscribed.

The wing halves were now joined.

The small vertical tail halves are

seen below here as well and car filler putty applied. Note that mating

surfaces are not yet treated, this will depend also on how these must be

positioned onto the fuselage after has been put together.

After sanding...

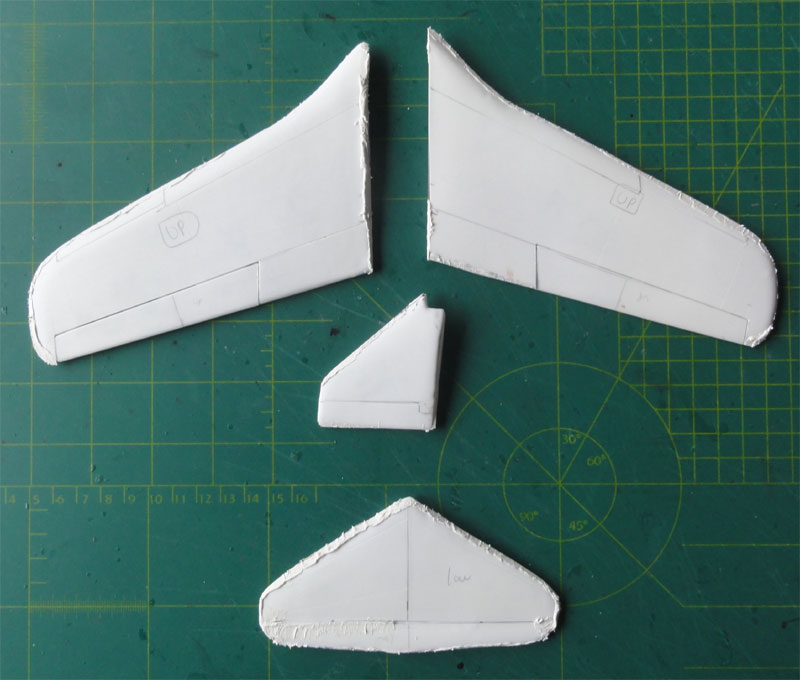

Continueing, I tackled the horizontal

stabilizer. I opted to make the elevator a seperate part, this will look

much better at this larger scale. So the sections were separated and joined.

The elevator was set in place with thin plastic card as connectors, glued

on the upper inner surfaces. The elevator ends have balance tabs and these

were filled. Also the trimtabs were not forgotten as these were inscribed

and their edges "sawed-in" with a razor saw.. Next, still some puttying

was needed. A final round of sanding made the trailing edge even thinner.

![]()

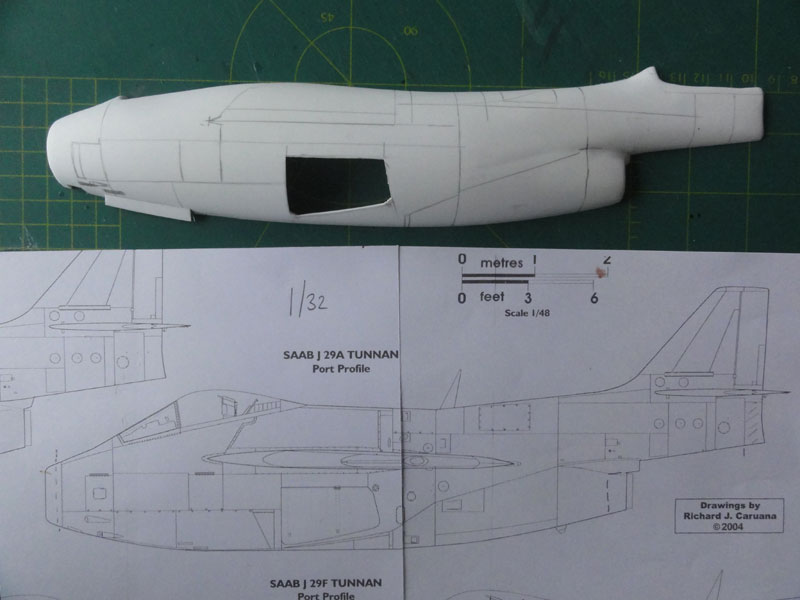

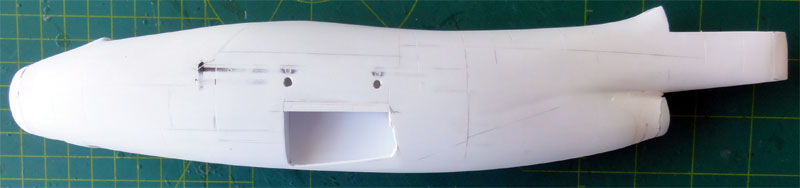

Next, the fuselage panel lines were

marked and the wheel bay and doors. The first panel lines were inscribed,

more will follow later. I feel that only a few rivets to be inscribed later

on as the J29 has at most panels flush rivets as usual for a fast jet.

An early J29A will be made through

this model, but of a bit later production model where the dive brake moved

from the wing to a position forward of the main wheel bays. (the tri-angle

panel drawn on the drawing). This dive brake swivels to the outside but

photos are scarce.

.

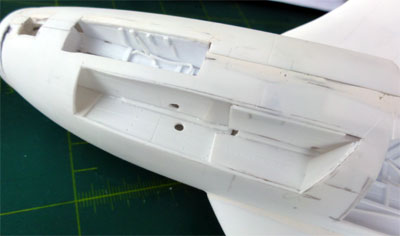

The main doors were cut out, inscribing

first and than deeper with a sharp X-acto knife and the razor saw trying

the retain the cut-out parts like the doors.

....

....

The result is very nice indeed.

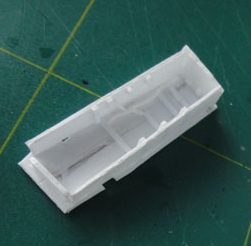

A nose wheel bay was also made from card.

A lot of internal fuselage details can be added through the various fuselage openings, so the fuselage halves could be joined. Think of undercarriage bay detail, cockpit, jet intake tube and exhaust. So no reason not to proceed further with basic fuselage assembly.

Pieces of sprue were glued on the edges inside the fuselage to get stonger joints and also strips of card were set at places inside. The nose gear bay was installed as well to get a stronger assembly at the nose section at this stage.

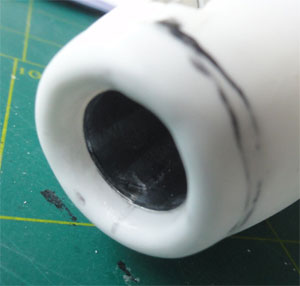

The nose intake ring is very nice as provided in the kit but I could not really check the opening. I estimated the inside diameter to be about 17 mm on the inside before it goes into the duct. I measured it also on a Heller 1/72 J29 kit and that confirmed about this size.

The vacu ring kit part was used to keep the nose section at the appropriate

diameter. Slices of plastic card were needed on top and lower edges to

fill any gaps here. Filling was done. (the lower J29 nose lights recess

was also opened up, not visible here).

..

..

Use plenty of fixing tape while the

lot dries. Sanding was done.

.

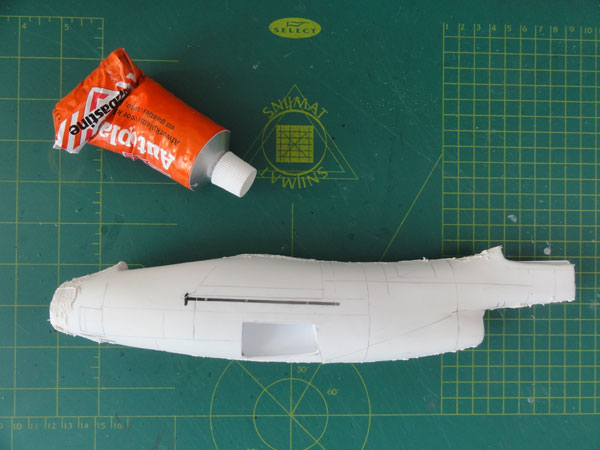

Filler was now used at various mating

areas. Sanding was done when dried out.

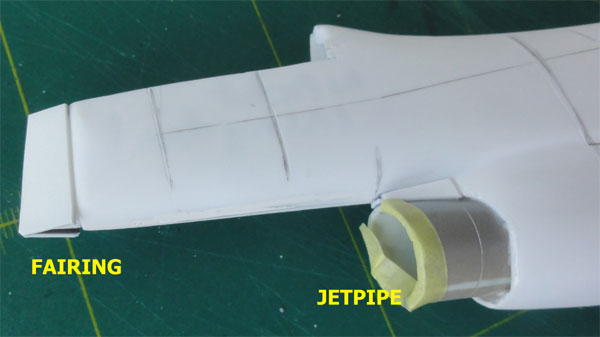

The jet pipe area was now tackled. The kit fuselage lower length is about 6 mm too small but it can be solved here as a tail pipe was installed and filled. I found an appropriate tail pipe in my spares box. (I think it was an F-5E jetpipe in 1/32 scale). Filler and sanding was again needed.

Also, a fairing was set at the rear

to get a tapered sharper rear end. This also corrected the overall length

of the fuselage and it looked much better now.

A.

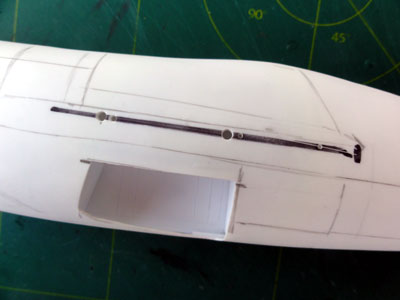

The wing position was checked again

and drawn using photos and the scale drawing. Some slight adjustment was

needed. Two holes were drilled to get later on two metal spars for the

wing.

.

The tail and horizontal stabilizer fitting on the rear fuselage end required careful alignment and a lot of filling and sanding. It was decided to do this at an early stage BEFORE fitting the two wing halves. The wing would interfere while sanding otherwise. So the stabilizer and tail were made now as a sub-assembly.

Filling and sanding was obviously

needed on the vacuform parts.

..

..

The sub-assembly was positioned at

the fuselage rear. The two metal spars, using purchased metal bicycle

wheel spokes, were set temporarily through the fuselage holes to help

with horizontal alignment.

Quite a big hole was there and a

lot of filling was needed at the rear. It took quite some effort.

![]()

The wing halves could now be installed.

The metal spars were used. Some strips of plastic were used on the spars

to be positioned inside to get a perfect horizontal wing without dihedral.

The fit of the wing halves required

minimal filler and sanding, so this was an easy job to do.

The result is seen here... The J29

TUNNAN is emerging!

Also the lower

view shows here the opened up nose light recess in front of the nose gear

bay. The model is still basic. w

![]()

The main gear bays were now detailed

using photos of the real J29 Tunnan using plastic sprue, rod and bits and

pieces. (The main undercarriage gear legs will be made using also metal

rods and fitted later).

![]()

Now, it was time to tackle the nose

intake.

The nose intake has a long tunnel

to the rear to provide air to the jet engine. I first mis-interpreted this

using an incorrect cut-away drawing!! Luckily my modelling friend Peter

had the photos that showed how the intake and its long tube should be!

This was also confirmed by other photos found in the internet (though of

a J29F and J29C). Plenty of photos can be found on the IPMS Nederland Walkaround

and many photos were made by my modelling friend Peter and myself.

See my information SCRAP

PAGE HERE....

For the tube I used thin metal sheet cut from a BBQ dish platter and rolled in shape. It is very thin and thus could be simply inserted through the nose intake ring from the front. First this was done half way. Than from the upper cockpit opening I installed an engine fan from the spares box to get a realistic look. The tube was pushed further to the rear. As the metal is very thin, the "step" at the nose intake is very small and can be filled with white glue.

..

..

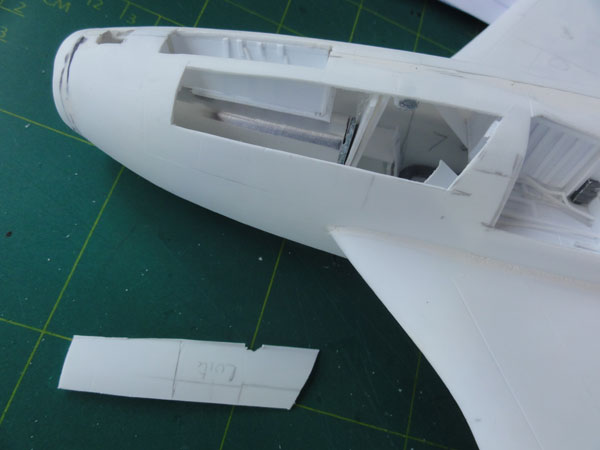

The basic cockpit area was now tackled. A floor was installed onto the intake tunnel and fixed also to the pre-installed bulkheads. In order to check the depth and alignment of the cockpit, first an instrument panel was made. The main instrument panel will be made later on.

Pre-fitting shows that the floor position is correct as there is just enough room and sufficient height for the ejection seat.

The basic cockpit interior is green, for which Gunze Sangyo 320 looks good (to be done later). The instrument details will be made and installed at a later stage.

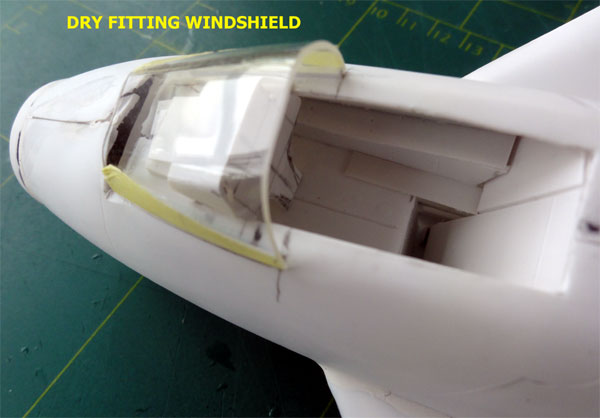

I also did a check to fit the canopy

and windscreen. Any errors in dimensions should be corrected at this stage

and not later!

The kit canopy is slightly too short

(about 2 mm) in length but that is fine to me. The windscreen and rear

sliding canopy section were separated with sharp scissors and razor saw

after THREE DOUBLE CHECKING! You only got one chance here and an error

is quickly made. So check photos, drawings and so on!

And here the windshield set in place

but not yet fixed. .

.

Strips were fitted to help fixing

the windshield later on. A lot of filling and sanding will be needed later

on, but the shapes are OK.

![]()

The basic assembly is now fine but

for a large scale kit I always wanted to show some more detail. It was

decided to open up the right side lower gun bay. This was carefully done

with the TIGER razor saw.

.

The bays were boxed-in with card,

details will follow later.

![]()

The overall model was now ready in

it's basic shape. Time to apply a first primer coat through grey paint

with the airbrush. This will reveal any flaws. Essential for a vacuform

kit that would get a vulnerable BARE METAL scheme.

Revell Aqua 75 Steingrau is a great

acrylic water based paint to use as primer. This was airbrushed.

The overall result looks good, but

carefull examination reveals some more filler on the surfaces and carefull

sanding is needed.

So more work to be done!

Back to 1/32 Models.......

(c) Copyright Meindert "designer"/ All rights reserved. Your comments are welcomed by webmaster

Created this page

May 16, 2016