[ Page 1 ]

1/32 scale Hunter T-7 FISHER conversion of Revell kit

.... to main Hunter page....

Page 1

Page 2

Page 3

kit review modelling report

FISHER MODEL AND PATTERN issued

a conversion set for use with the injection moulded 1/32 Revell kit.

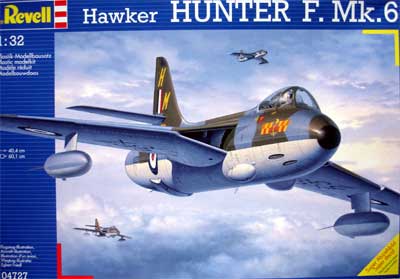

In 2006 Revell issued a Hunter F.mk6

kit (No.04727 ) and that can be used, but also the Swiss kit FGA9/mk 58

can be used if you only get your hands on this one. The conversion set

was ordered directly from the USA.

http://www.fishermodels.com

![]()

Decals are available from FLEVO

decals for a Dutch AF Hunter T.7 so what would prevent me making a

nice 1/32 model?

A great walk around of the T-8C is

seen on the Dutch

IPMS website here.... (Note: the T-8C Hunter looks a lot like

a T-7, but is seen with red anti-collision lights at the spine and in front

of airbrake and it has an arrestor hook. On the Dutch T-7 Hunters, these

are not present. Also in the T-7 cockpit, gun sights are present).

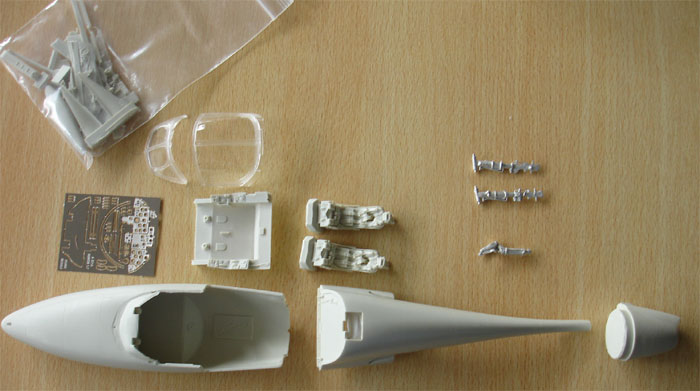

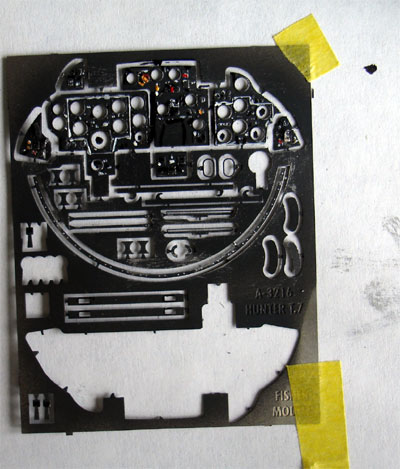

The main parts in the FISHER MODEL

AND PATTERN HUNTER T-7 Conversion set are resin main parts, metal undercarriage

legs to carry the heavy weight, etched metal instrument panels and details

and a clear resin canopy and windshield. Also RAF decals are provided.

You get a written set of instructions

with the conversion set along with assembly photos.

Working on the resin parts,

separating them from the casting moulds:

The resin moulded two seater canopy. It will benefit from dipping it into Johnson Future/Pledge acrylic coat to have a better shiny look. The canopy is very fragile so take care not to break it!

.

.

Decals for RAF planes in the FISHER

set:

.

.

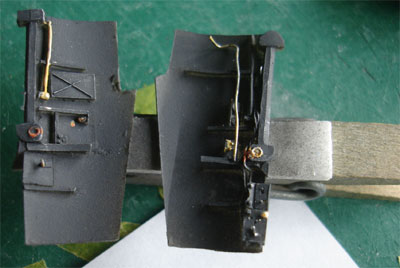

Two very nice Martin Baker seats are

provided with the FISHER set:

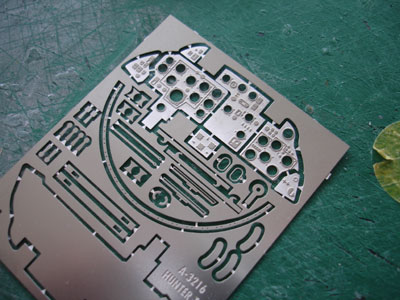

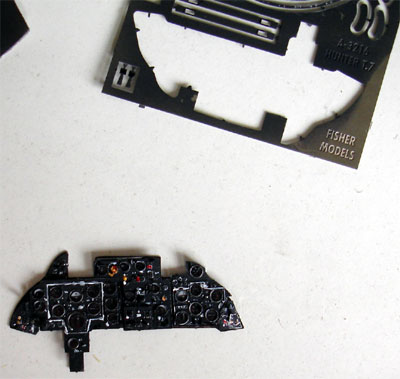

The instrument panels are also included

and have several etched metal plates as seen here:

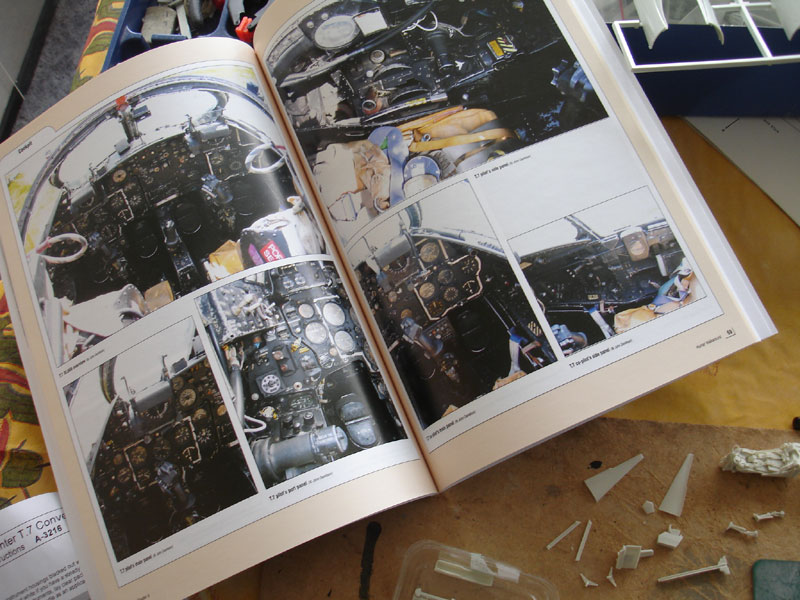

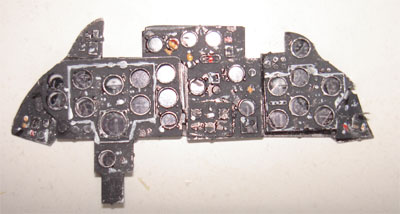

How the real T-7 panels look like:

The FISHER parts were separated from

their moulding blocks, cleaned up and ready to get a first coat of light

grey

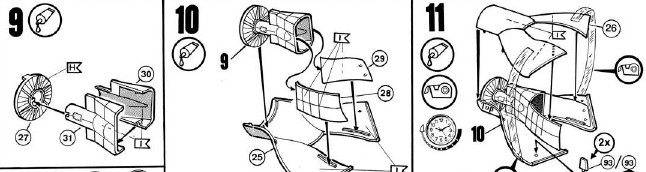

On to assembly using the Revell F.mk6 instructions of the Revell 1/32 kit. (for the FGA9/mk 58 step numbers indicated are slightly different). Please note that the STEP numbers here are based on this F mk.6 kit's instructions.

Step "0" Model preparation

The Revell kit spine should be reduced

in length, do not use the incorrect figures of FISHER but measure

your self using the forward FISHER fuselage and spine as a guide.

Indeed do not fit at this stage the new resin spine to the resin cockpit, the cockpit floor will not fit through the remaining opening. So it is important to finish up the cockpit interior first so far that the floor can be fitted.

Steps 1-8

can be skipped as they deal with

the cockpit, use the FISHER instructions.

For the smaller resin and metal parts CA glue was used, for fixing the larger parts 2-component expoxy glue.

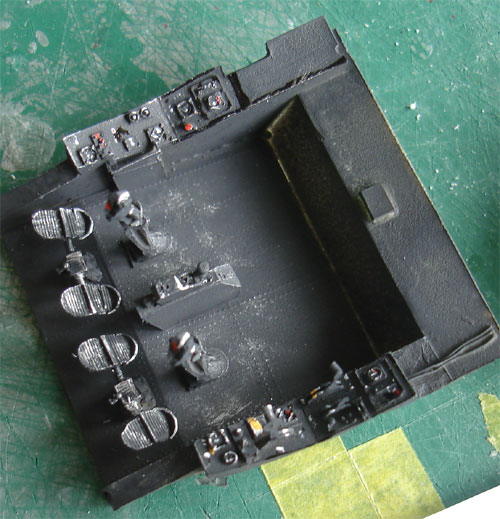

The FISHER floor is very very thin

and I think the depth a bit undeep, probably the nose gear bay is a bit

to deep. But nothing that is disturbing. For the cockpit numerous details

were prepared such as the side walls and assembled, ready for installment.

The frets and interior were airbrushed. Working on the T-7 cockpit interior,

using several layers with the FISHER parts and the supplied decals:

.

.

The overall colour of the Hunter

cockpit is "black" as common for fighter types of that period. A dark grey/black

mix

was used including drybrushing

to

show of the detail and to prevent a "coal hole". (obviously do not fit

the seats yet).

Dials and instrument are provided

as well in the FISHER set, to be set aft of the panel. The instruments

were covered by transparant Micro Kristal Clear later on.

.

.

All the cockpit parts were fitted

in the resin nose, this is needed prior to fitting it to the rear fuselage.

The side walls need some trimming at there lower edges by about 3 mm otherwise

they do not fit.

The hole for taking the swivelling

canopy mechanism should be kept clear, a covering plate is provided in

the set.

Some filling and sanding is needed

at the sides, but this can be easily done now at this stage and not later

as to avoid the intakes obstructing the work. The finished forward cockpit

and nose section was set aside.

Now I continued with the rear fuselage.

Step 9

The main intake duct. Fill the ejector

pin marks in parts #25 + 26, paint and assemble as shown. The intake ducts

take tape to glue them correctly.

.

.

Steps 12-13 can be skipped for now.

Step 14

Use the FISHER rear end part. I cut

off the sides of the resin exhaust part for a better fit:

The rear fuselage requires some tape

and persuation to get a good result.

Some filling is needed to get a nice

result at the exhaust area with the parapack fairing. Take care with the

fragile thin fairing edges.

.

.

Steps 19-20 can be skipped

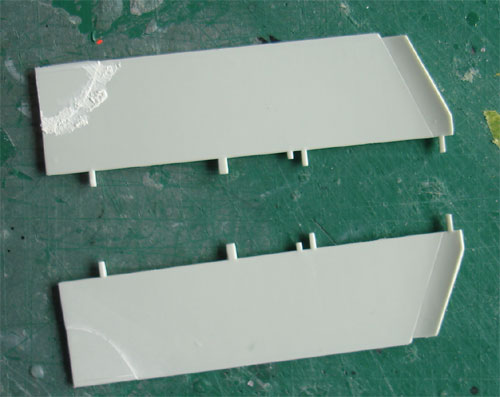

Step 15

The trailing edge droop flap (parts

# 41 and 48) have a small cut-out for the larger wing tanks. On the mk.4

and T-7 these were not present. Simply cut of the corner of the lower wing

halve and reposition onto the flap. Fill and sand.

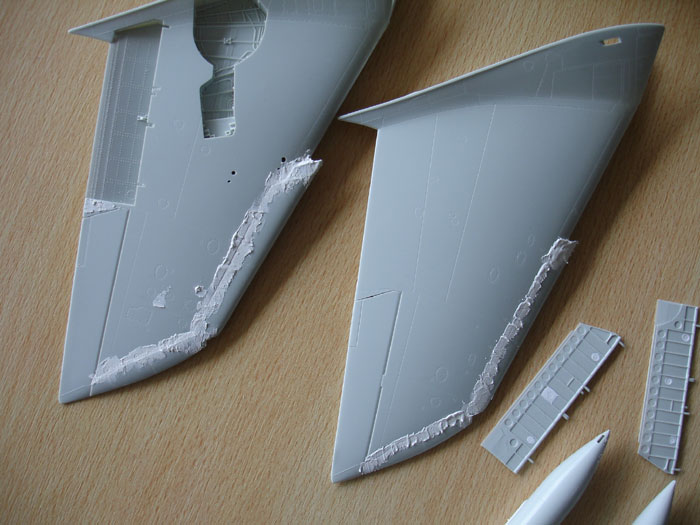

Step 17

Assemble the wing as shown in the

Revell instructions.

IMPROVEMENT

SUGGESTION:

The openings

for the inner pylons (see STEP 43 -46) for the 100 gallons tanks are too

far outboard and should be positioned 2 mm and in parallel with the leading

edge in 1/32 scale more inboard! This will improve the look of the Hunter

model.

Make new holes

and fill up the incorrect holes.

Also, the wing

sawtooth should extend 4 mm more inboard as compared to that on the kit.

I added this extension on both wing halves with card and putty.

The wing root slots were opened up

and the leading edge extension filled and sanded. The aileron edges were

sawed to get a see through effect with the razor saw.

The completed and corrected LE extension

tooth.

The intake slots were cut open as

well.

Step 18

Skip for now, leave for later.

Steps 19-20 can be skipped as the exhaust has already been fitted.

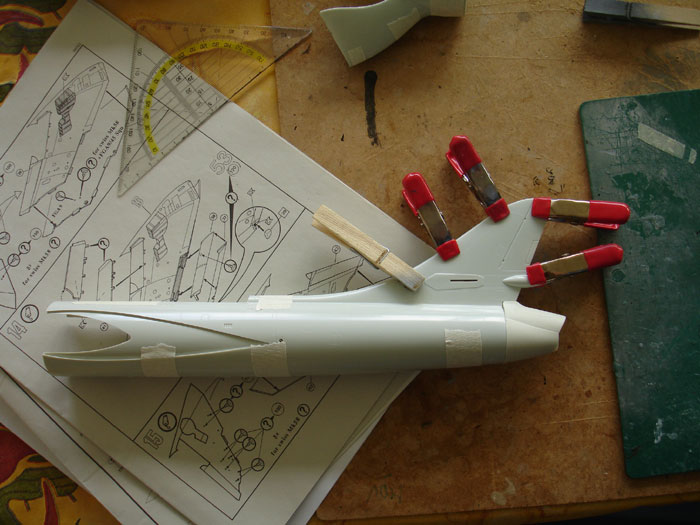

Step 13

The intake ducts are now set inside

the rear fuselage, but not yet glued in place. Next was fitting the T-7

forward fuselage to the rear fuselage.

Sand and putty the whole fuselage

with exhaust + main + front sections as needed now as you can now easily

handle the fuselage. The lower area needs filler and considerable

sanding... There is a "step".

.

Back to 1/32 Models.......

(c) Copyright Meindert "designer"/ All rights reserved. Your comments are welcomed by webmaster

Created this page

June 25, 2010