[ conversion page 2 ]

1/32 conversion to build a T-45 Goshawk US NAVY jet trainer

... back to page 1

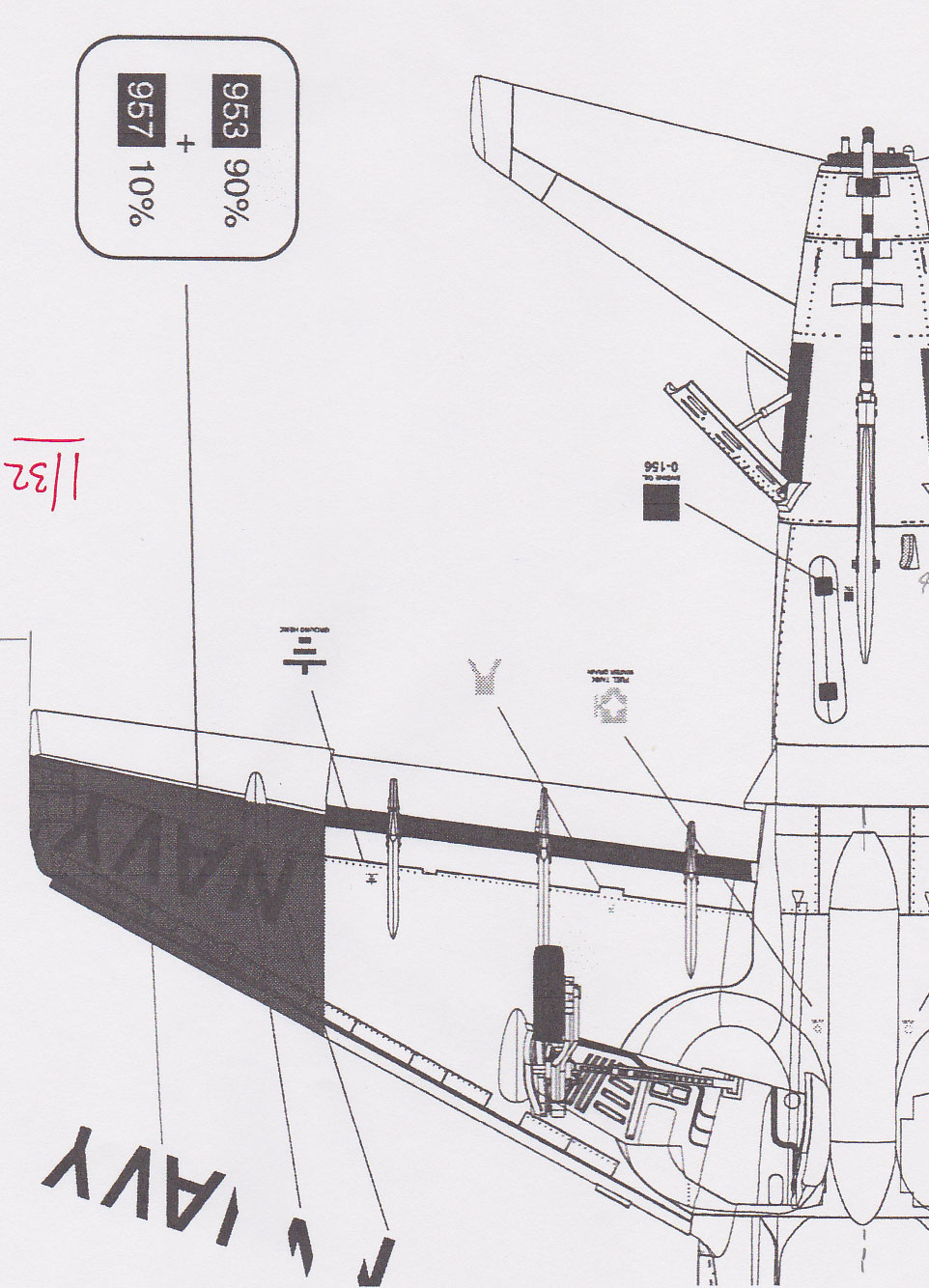

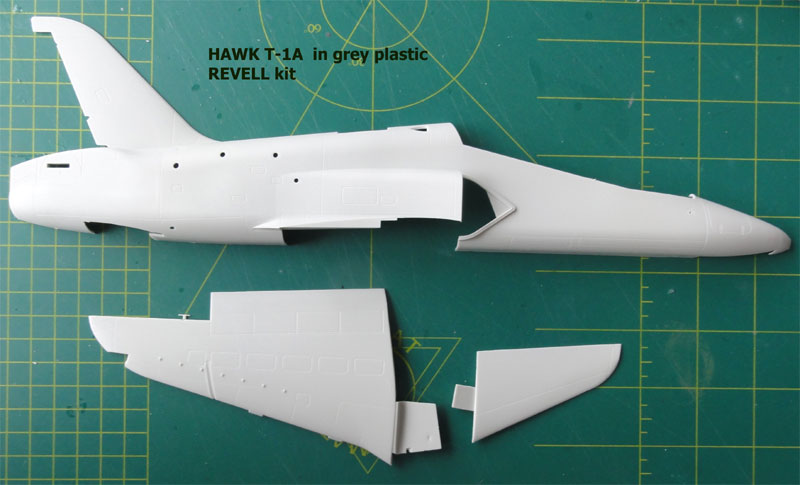

So the starting point is the Revell

1/32 Hawk T.1 using T.1 kit #04849 with friendly grey coloured

plastic.

I also checked out if there were any 1/32 markings for a T-45 Goshawk. To my surprise, DRAW DECALS has made a couple of silk printed decals for Centennial anniversary Goshawks. One of these sets will be purchased.

![]()

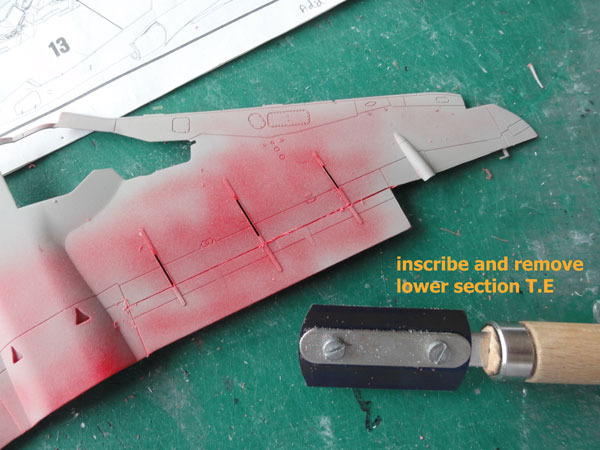

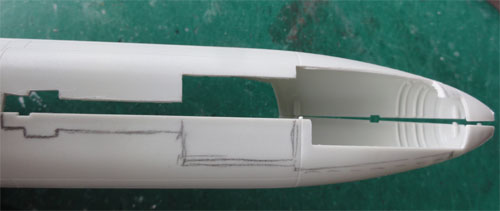

Flap separation

First, the major "razor saw" work

will be done on the main parts as they can now be well handled.

First, a ageneral change is needed

on all the Revell Hawk kits in 1/32 scale:

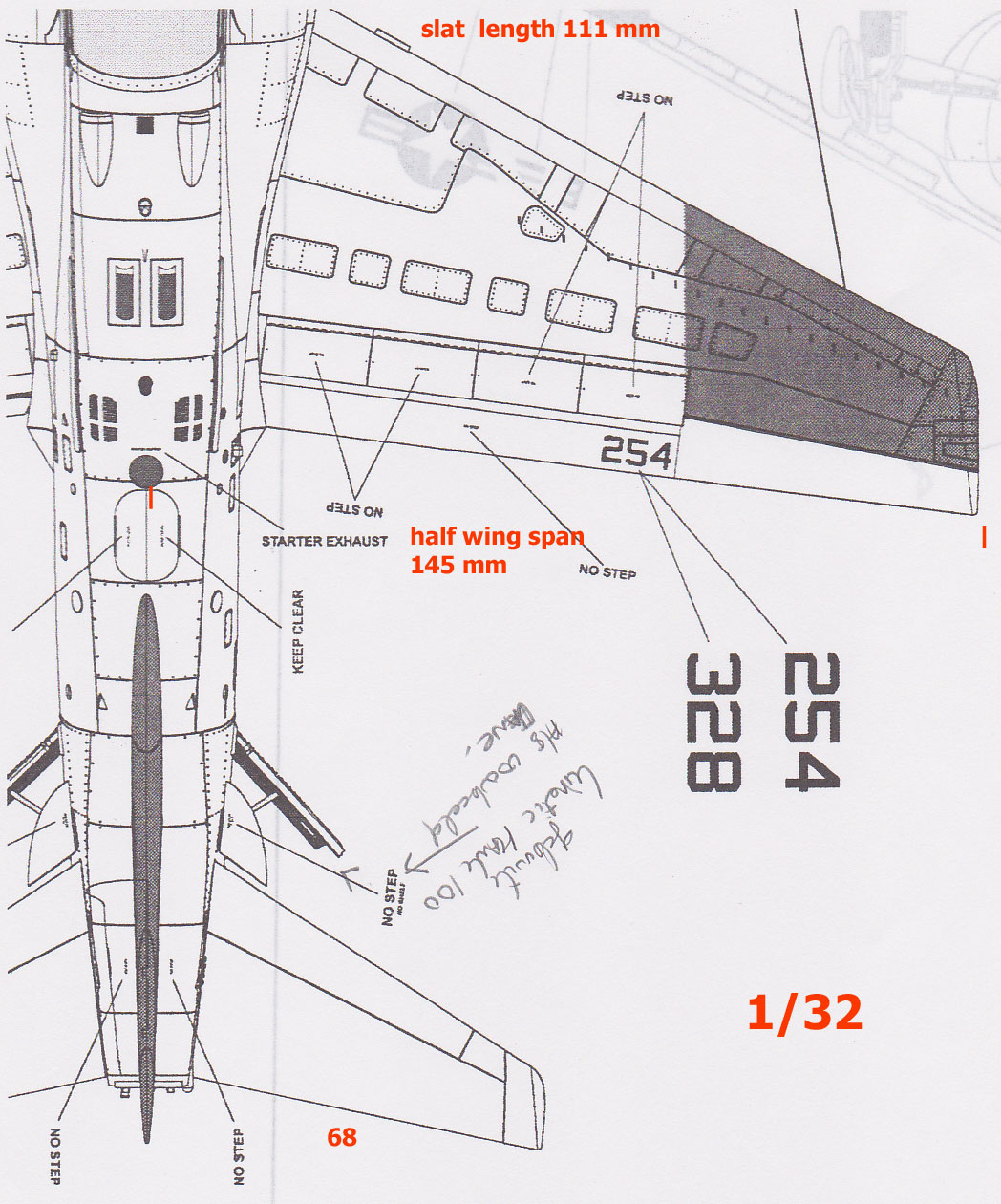

Real Hawk show always the trailing

edge slotted flaps drooped. Unfortunately, in the Revell kit , the flaps

are NOT a separate parts. (On the 1/32 KINETIC Hawk 100 series, the flaps

are indeed separate parts, well done Kinetic).

So we need on this Revell kit to

separate with a razor saw the rear flap.

The flap edges are well indicated

on the kit wing parts. (here seen on another Hawk also being build, with

the red plastic).

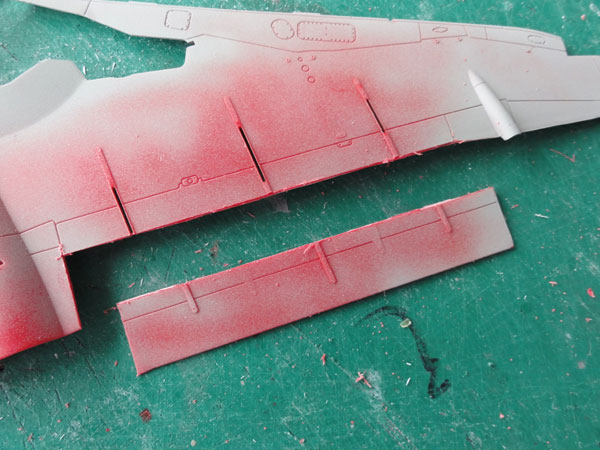

The trailing edge flaps are needed

later on. A small gap at the end are closed with card and filled and sanded

in shape later on. Also a flap vane needs to be made, to be done later.

![]()

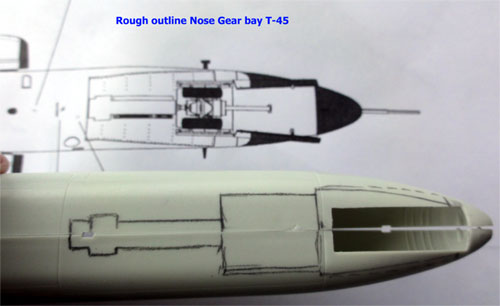

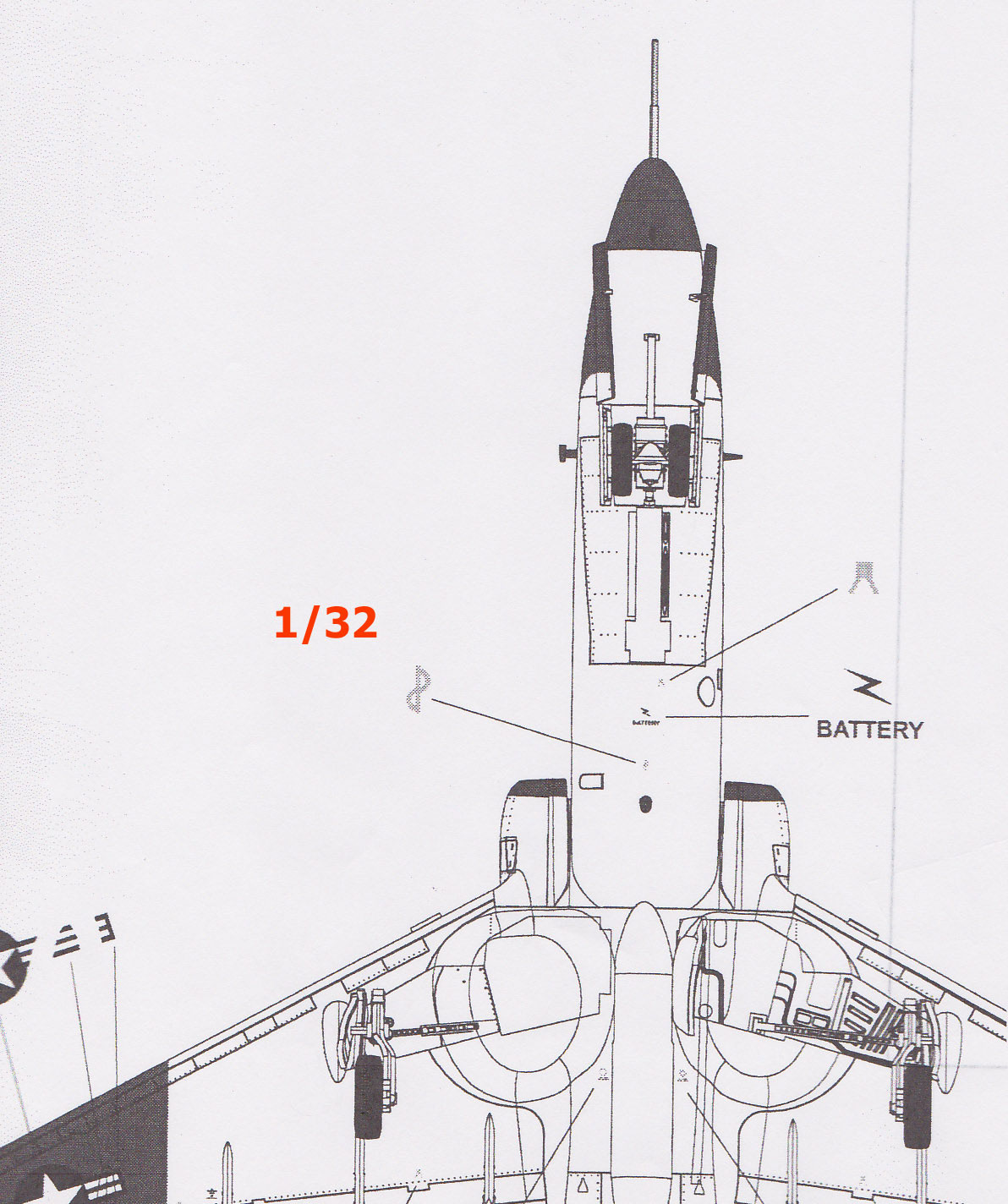

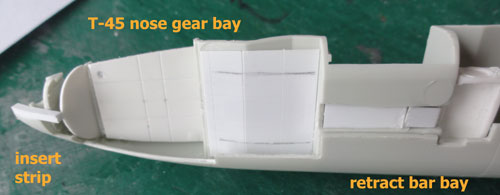

D- twin nose wheel gear with catapult

launch bar (and larger nose wheel diameter)

The nose wheel bay is significantly

different on the T-45.

The outline was pencilled and with

a TIGER razor saw cut out on both fuselage halves.

This is a drawing that shows it in

more detail.

The result is seen here.

.

A new nose wheel bay interior is required,

this will be made from plastic cart. The recess/bay for the stress (retract-)

bar required cutting out a central piece of the kit cockpit tub (part #1)

.

On the upper floor a very thin piece

of cart is set to cover the gap.

On the forward nose, an insert plastic strip is set of 2 mm wide. This will give the T-45 a bit deeper nose as on the real aircraft to accommodate the large twin wheel nose gear.

Later on, when other main (internal)

fuselage assembly is complete, the fuselage halves will be closed.

The rest of the nose gear assembly

is done at a later stage.

![]()

STEPs 17 - 20 of Kit instructions

(wing assembly)

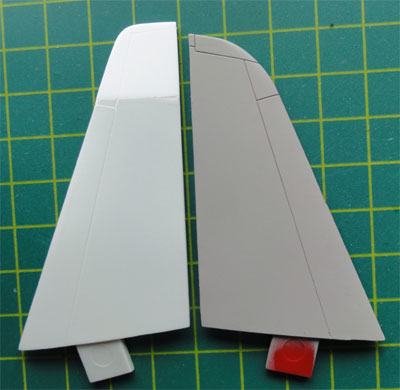

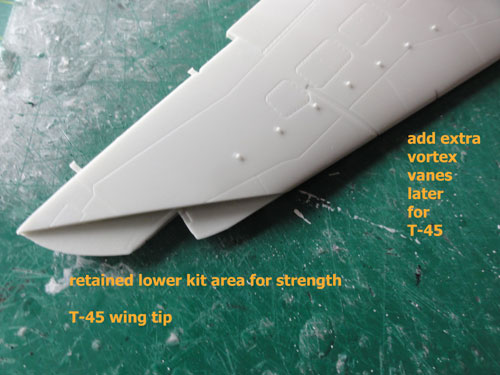

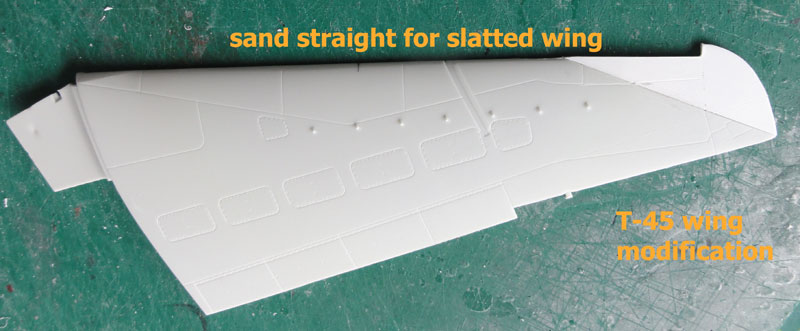

B- slatted wing with straight leading edge and with adapted wing tips

The T-45 wing does not have a larger span as compared to the Hawk, but the wing tips are different and there is a straight wing leading edge. On this leading edge, on the T-45 a slat was fitted. This slat enables low approach speeds (as needed for carrier landing training).

The kit part tips were sawed off,

this was done only at the UPPER wing half panels ( parts #66 , #70 ).

The lower wing parts will be used

unchanged to retain strength and with plastic cart and putty will be shaped.

The rest of wing assembly is for later. (this will also need adding extra vortex generators on the upper wing surface).

![]()

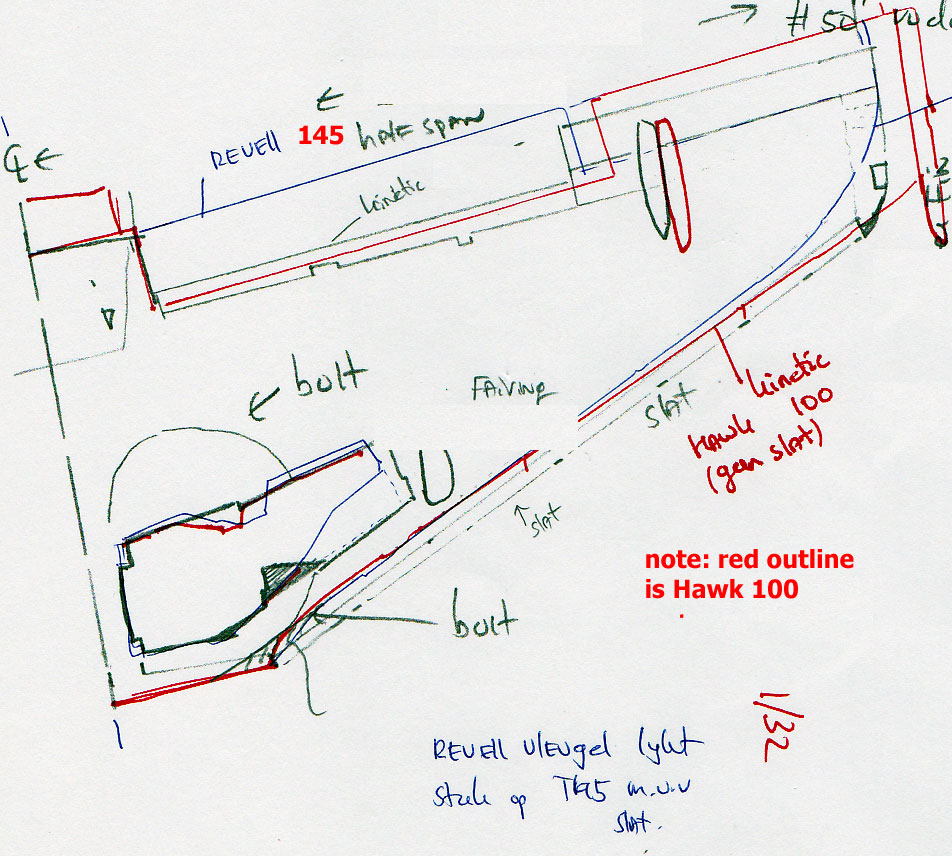

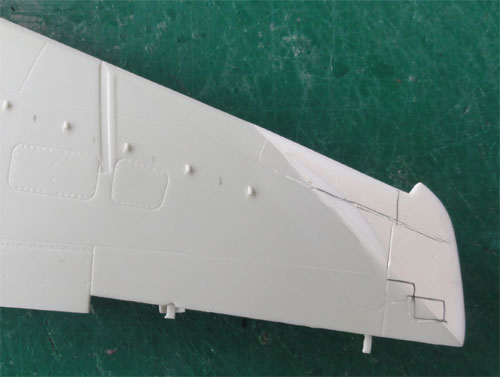

F- stronger undercarriage with

larger main gear (bulged) bays

The T-45 has a beefed up main wheel gear, and the fairing at the wheelbay is a bit bulged. A cut was made and the inner central area bended.

.

.

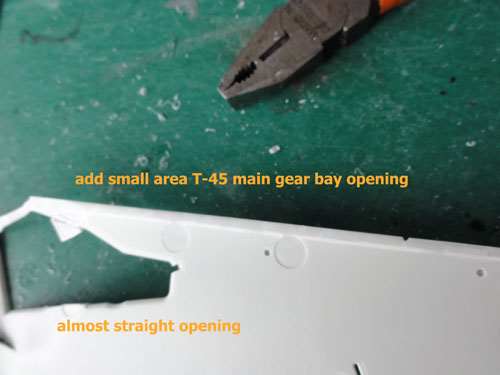

The shape of the main wheel bay opening

is also bit different. A straight aft edge is needed, sand to shape. Also,

add a small tri-angle of the forward edge.

Use the drawing as a guide.

The wing tips were shaped with cart and putty.

The leading edge was sanded straight

in shape. (a drooped slat will be fitted later on). Note the the wing chord

will be a bit larger due to the slat, and this is probably right; no data

was found on the exact spanwise T-45 wing chords.

So no extra areas were removed on

the kit wing leading edge itself. The slat part will be drooped and if

not entirely correct, will not show such a small error.

Now fill and when dry, sand in shape.

Some refilling still needed here....

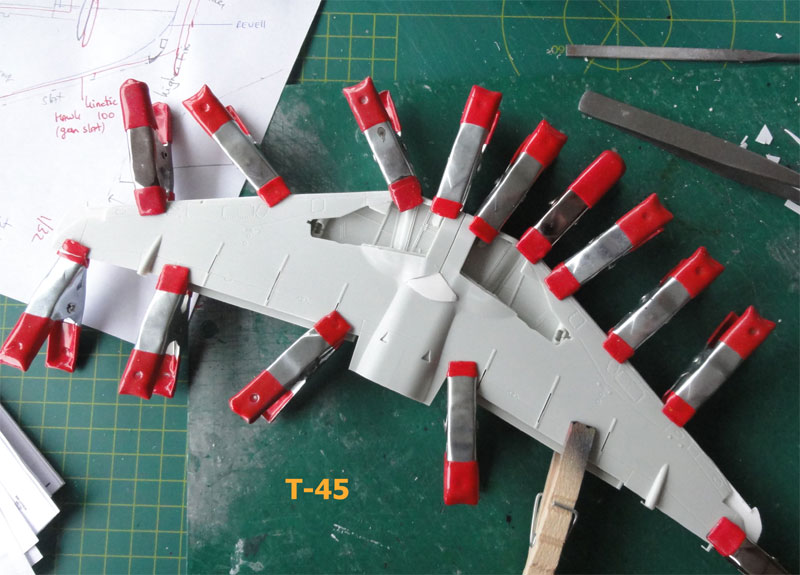

Now, look at kit assembly STEPs

17 + 18.

The kit parts for the bay sides were

set in place. On top of the inner sides, a 2 mm thick strip was glued,

this will make the bay deeper. (this was required to accommodate the thicker

wheel strut). The bended structure was glued on as well as the prepared

wing halves. The gaps were filled with putty and when dry sanded in shape.

Finally, the overall T-45 wing can

be assembled...

The lower wing tips still need filling

and sanding.

H- large span and squared tipped tailplanes

The T-45 tailplanes have a 10 cmm large span and the ends are not curved as on the Hawk. This was done to improve T-45 stalling characteristics. Also, the T-45 has the small flow vanes as seen on later Hawk 100 series aircraft, again to improve stalling behaviour.

See kit STEPs 23 + 24.

The kit parts were cut straight and

with card the span increased with 3 mm, see the drawing.

The tailplane stabilizer trailing

edge should be 68 mm long.

(on the right, the Hawk stab.)

On to next [ page T3...]

Back to 1/32 Models.......

(c) Copyright Meindert "designer"/ All rights reserved. Your comments are welcomed by webmaster

Created this page

May 25, 2013