[ Page 2 ]

Parts preparation and parts separation needed mainly an X-acto knife to score along the edges to remove moulding stubs. Some minor use was made of a razor saw to saw through some fiberglass enforced parts.

Main resin/fiberglass parts will be glued with 2-component epoxy glue, smaller parts with Lock Tite "thick" superglue.

OK, let go on with the kit.....

STEPs 1 - 16

These steps deal with the seat assembly

and some cockpit panels. Very good parts for the instrument panels are

in the kit, some of pre-painted etched metal and some resin add ons. These

were NOT yet installed at this stage, will be done later after painting

the basic model.

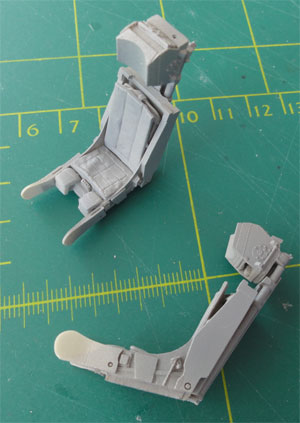

The VS-1 ejection seats designed in Czechoslovakia in the kit are very nice. They come

with a full harness, these are not yet fitted as the seats got first a

grey pimer with the airbrush.

NOTE: Later I found out that the REAR kit seat should be reduced 3 mm in height! So sand away 3 mm from the base of one of the seats, better do this now!

STEPs 23-26

STEP 31

Here also the forward fuselage is

seen. Inside the cockpit, the side wall details were added and a first

coat of grey applied. Note the cut out entry ladder recesses .

Main resin parts gleuing is done with

2 component epoxy glue. This has additional strength on some glue

the larger parts like fuselage and nose halves, wing parts and tails with

expoxy. I used BISON COMBI POWER

Also, I usually use car filler putty.

Here in The Netherlands the white "Alabastine"

auto plamuur is a good choice.

STEPs 37-47

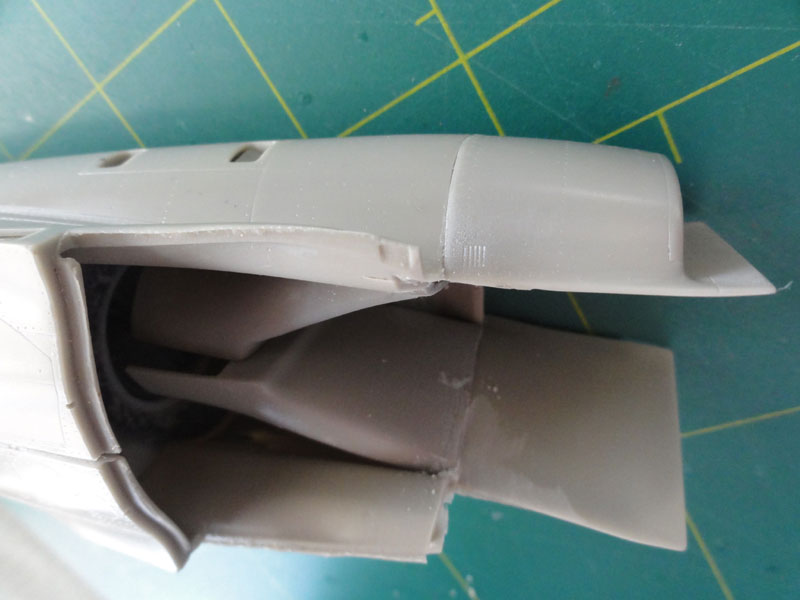

I had some trouble to get the intake

tunnel completely correct, but not a lot is seen later inside. I reduced

the intake tunnel length by 3 mm at the rear of parts 54 and 55. The fan

details of STEP 37 are hardly seen as well.

The exhaust pipe fits well and needs

to be inserted as shown per instructions.

STEP 46

Assembly continued, joining the intake

and rear fuselage first. This will help alignment. The edges between forward

fuselage and intake need sanding and carefull assembly work. The strengthening

rods as seen in STEP 45 are not yet fitted as the forward fuselage is not

yet joined.

First some car filler (see above)

putty was applied and first sanding done to close gaps. This is better

done at various stages for better handling.

STEPs 47-48

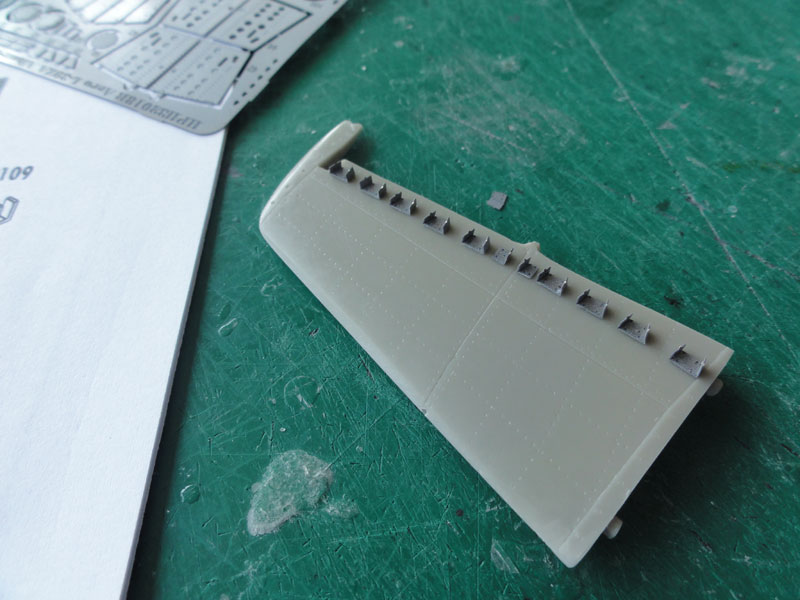

The rear horizontal tailplane is

nicely detailed complete with the air flow vortex generators supplied as

etched metal parts.

I could not find parts 89, they were

overlooked?

STEPs 52-56

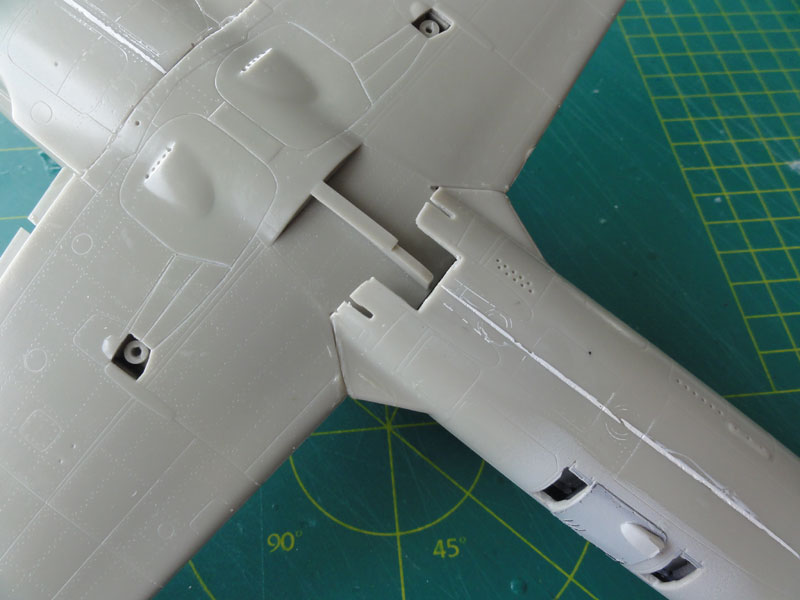

The main wing was also assembled.

The gear bays are not very well seen as the gear bay doors are closed when

a L-39 is parked. And so they are moulded closed in the kit. The door outlines

were inscribed a bit more pronounced with an Olfa P-cutter.

Some putty is needed particularly

at the leading edge, also filling tiny air bubbles in the resin.

The moulding stubs for the resin are seen above and are easily removed by scoring in the edges with an X-acto knife. The stubs will separate from the parts.

NOTE: I found out later that I should have removed the main gear bays doors!! This is NOT shown in the HPH kit instructions in STEP 67! I recommend you do that now at this point. So open up the main gear bay! The main doors are separate kit parts # 67+68.

At the wing tip tanks, lights are

fitted. The moulding showed some fit problems and gaps. Putty is thus the

solution. Particularly at the moulded wing tip pods.

The trailing edge flaps are not yet

fitted at this stage.

STEPs 32-35

The cockpit tub was now inserted

as well as the provided metal nose weight in the forward fuselage / nose.

The tub itself was not detailed yet

with all cockpit parts at this stage though to prevent damage later on

during further assembly. It got a first dark grey coat of FS34226 using

Gunze Sangyo acrylic H335 as well as the instrument covers and bulkheads.

The joining of the forward and rear

fuselage was not easy. The assembly needs a lot of carefull alignment work

with not much room to manoeuvrer.

A gap needs to be filled as well

with card and putty in an awkward place. But it can be done.

Car body Filler / putty was applied

and after drying sanded.

The fitting of the strengthening

rods is very carefull work. I cut metal rods from a paperclip. The correct

location is seen in the insides of the intake lips. Use super glue.

The main fuselage and wing is now

ready for further kit assembly.

..

(c) Copyright Meindert "designer"/ All rights reserved. Your comments are welcomed by webmaster

Created this page

May 8, 2014

Updated June 16