F9F-5 Panther

[Page 1]

Panther model in 1/32 scale of FISHER MODEL AND PATTERN

Panther photographed by me at Pima in 1991

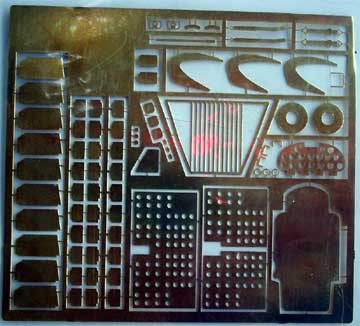

Fisher Model and Pattern issued a 1/32 kit of the Grumman F9F-5 Panther as kit number #3201 in 2005. It is a very impressive kit in full resin with additional etched metal parts and nice decals including stencilling.

The Panther kit costs about U$ 150,= and although that looks not cheap, you get a very impressive and nice model well worth the money. Certainly compared to good injection moulded 1/32 kits, the price is competitive.

The kit was ordered directly through the Internet http://fishermodels.com/ site

... and came in a very sturdy box

within a month.

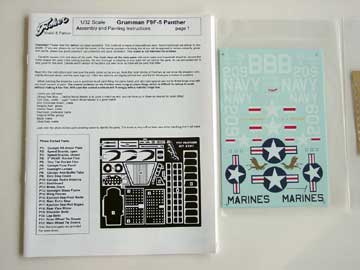

Instructions are comprehensive and

have a personal touch as Paul Fisher clearly shows you how to get most

out of this model with a step by step description and black and white pictures.

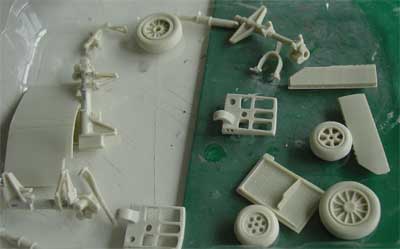

The resin parts are executed in a superior

fashion with a clever kit parts breakdown. The resin is very sturdy and

has a fine surface texture and need minimal trimming and removal of resin

flash.

The decals are also very well printed.

Cleaning up the parts takes no more

than a few hours. Clearly, this company has a lot a experience moulding

resin models, most of them being very nice resin kit of cars. Resin may be harmful, so read my resin handling tips here...

You get in the Panther kit various

optionable parts such as separate flaps, choice of how to make the canopy,

choice of weapons and stores and also very nice additional options such

as speed brakes. All the parts of mainly resin and etched metal are impressive.

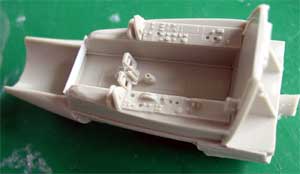

Cockpit is well detailed with a very nice seat, instrument panels, side

walls etc etc.

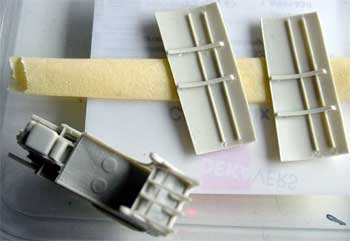

The undercarriage legs have metal

rods moulded in to get the necessary strength as the model in resin weighs

quite a lot. You also get some "spare parts" in areas in case you loose

on or when there are some options such as tow types of main wheels.

Parts fit is very good with minimal

filler being required at the wing-fuselage junction. Before starting the

assembly and painting, thoroughly clean up all the parts with a bath of

water and soap.

Assembly is rather simple just as

a "normal kit" using superglue and two-component bonding glue.

OK, let's begin...

The cockpit section is very well detailed.

Drybrushing revealed the various details on the side walls etc.

I used some home made instrument decals

to make the main instrument panel.

The seat is very nice with straps

to be added from masking tape.

Also add enough counter weight! Use

small "Dollar" or "Euro" coins.

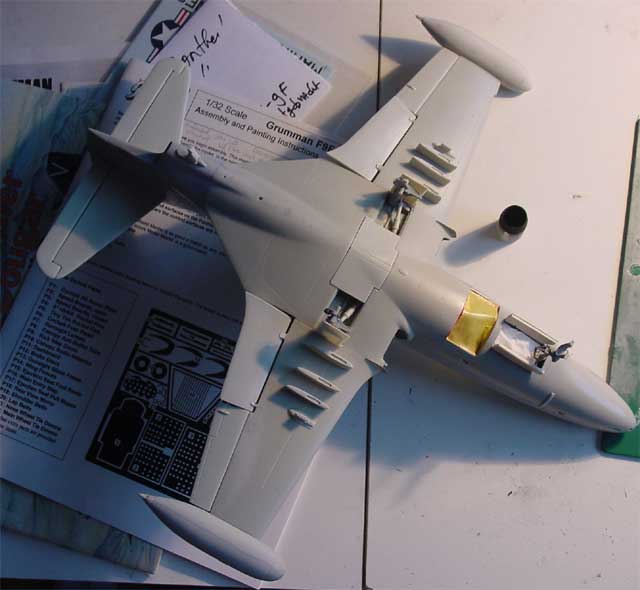

Speed brakes were set half open and

have nice detail (with metal parts). The bay was painted red and is seen

here masked for spraying.

Flaps, aileron and stabilizer are

very nice separate parts. I suspect the slats have to extend and droop

a bit when flaps are also drooped. As the kit has no separate slats, I

only drooped the rear trailing edge flaps a few degrees.

Filled gaps can be cleaned up using

nailpolish remover. This minimizes the otherwise required sanding.

After the assembly, the overall model

got a light grey primer (using Revell 75 light grey) ; this will reveal

any small flaws and gaps that need some attention. After that a first coat

of dark gloss sea blue was airbrushed and the model was side aside for

a couple of weeks.

After a while a problem was discovered a big issue with the large wing part. After fitting the heavy tiptanks, it would not stay straight but bended as seen here....

When the model was turned upside down, the bending continued towards the other side using the law of gravity. So the problem was not a "memory" problem in the resin.

After sending an email to Fisher Model and Pattern, I was told that the problem was indeed not caused by the resin having a "memory" but was really caused by an error during resin production and now definitely resolved.

Paul Fisher instantly sent me a new wing and even some extra parts at no cost. So a very dedicated and good customer service from Paul Fisher.

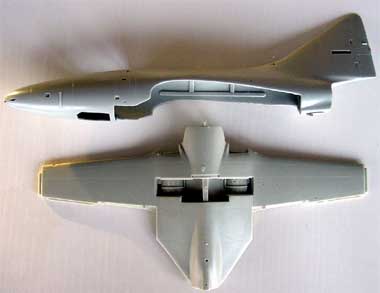

I "brook off the old wing"... a risky thing but it worked out. I fitted the new wing part and the problem was solved. In the picture the upper blue wing is the old wing, the lower gray wing the new straight replacement resin part.

It was fitted to the Panther without further problems.

So now back to assembly.

The undercarriage legs got some extra brake hydraulic lines made from thin metal wire.

For the under wing stores a lot of optional stores are given which are all excellent. Select what you want and choose the appropriate provided pylon.

For creating the canopy different options are given.

I choose the nice "clear resin" part which was OK.

Leading edges were airbrushed in dull aluminum after masking.

...

Squadron Signal Publications : Panther / Cougar book

On Internet:

IPMS NL F9F walk around of my modelling friend Cees

http://en.wikipedia.org/wiki/Grumman_F9F_Panther

http://www.aviation-history.com/grumman/f9f.html

http://www.angelfire.com/space/grumman/aircraft/panther.html

(c) Copyright "designer"/ All rights reserved. Your comments are welcomed by webmaster

Created November 18, 2005