ITALERI

[ Page 3 ]

F-35A in 1/32 scale: kit review & modelling report of the ITALERI kit

page 2

page 3

page 4

... continued from F-35 page 2....

OK, on to modelling this F-35A.

PREPARATIONS BEFORE ASSEMBLY

First I filled the rather awkward injection pin marks on the insides of the doors, intakes and so on. These were puttied and sanded flat when dried.

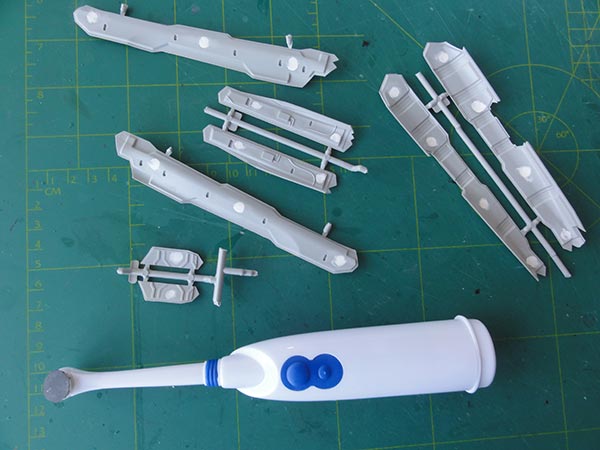

I use for sanding in confined spaces my modified electrical toothbrush. This is a cheap simple tool running on batteries where the "brush hairs" were removed and with double sided tape a piece of round cut waterproof sand paper is set in place.

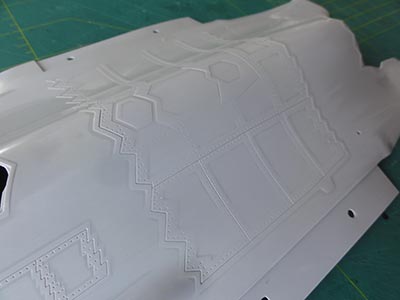

On the upper and lower large fuselage halves, I started with reducing the thickness of the raised zig-zag panels.

I did not remove them completely but it is almost a flush result by reducing their thickness through even sanding. Try to use the same pressure while sanding with a sanding block to get an even appearance.

Before and...

...after

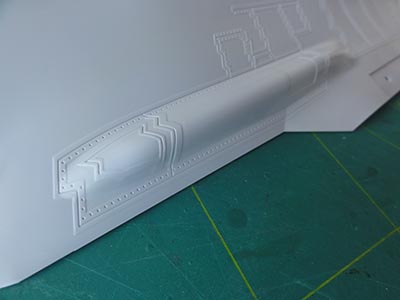

The upper areas were also sanded to get a bit thinner raised panels.

I sanded flat the raised details on the cockpit sides at the upper section near the cockpit opening. They seem to be far too thick.

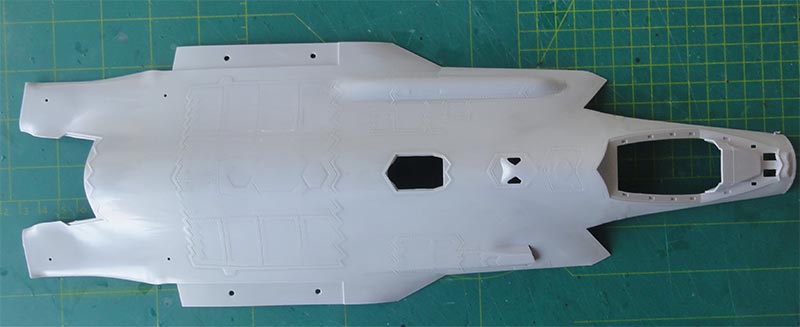

and the lower fuselage halve...

On the upper fuselage as noted before as well at the left intake...

(5a) the bulged fairing on the left intake contains the gun barells and a hatch that opens when the gun is fired. This fairing of the kit on top of the left intake seems a bit to sharp.

I first taped the surrounding area to protect it. Next I sanded carefully the upper areas of the fairing and made the upper section more rounded.

The fairing seen before sanding...

... and after sanding

I also re-inscribed the gun hatch and some other panellines.

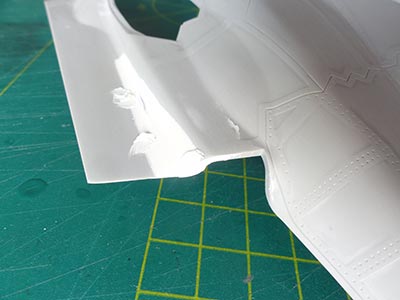

As noted on page 2, I noted that on the lower fuselage....

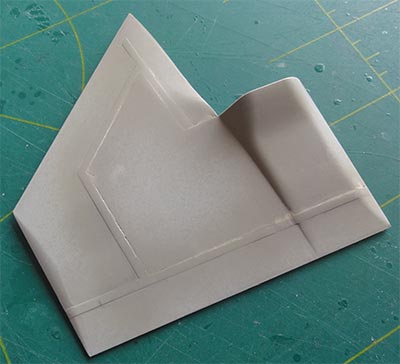

(4a) The central bulge (with inside the arrestor hook) at the rear engine section of the kit seems to be a little "too pronounced".

I added a piece of plastic strip for guidance and added some layers of car filler putty the sides.

Also...

(4b) The outher left and right fairings for the wheel bays look a bit to sharp angled. This is seen best at the left flap-fairing junction but on the right it seems that this is only a small difference. Also, the curve at each separate flaperon was filled and sanded.

.

.

Here also, I added a strip and filled the curve with some layers of putty.

(4c) The IPP (a very advanced sort of APU and emergency energy system) exhaust seems to be a little too small and should be a little more a bigger but smooth bulge. I added a round section of plastic card and putty. This will be sanded to create a bigger exhaust area.

This was sanded and puttied a few times before it looked OK.

and the results...

..

..still a little bit filling and sanding needed...

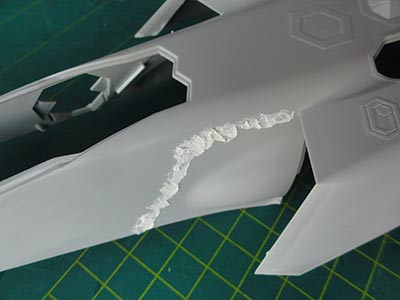

This is the final result. Reshaped areas have gotten a light grey base coat to see any small imperfections. But the lower area now looks much better as compared to the original kit.

... as well as the slightly re-shaped flap fairings

The side panels at the nose near the intakes were set in place and needed a bit filler.

FIRST ASSEMBLIES

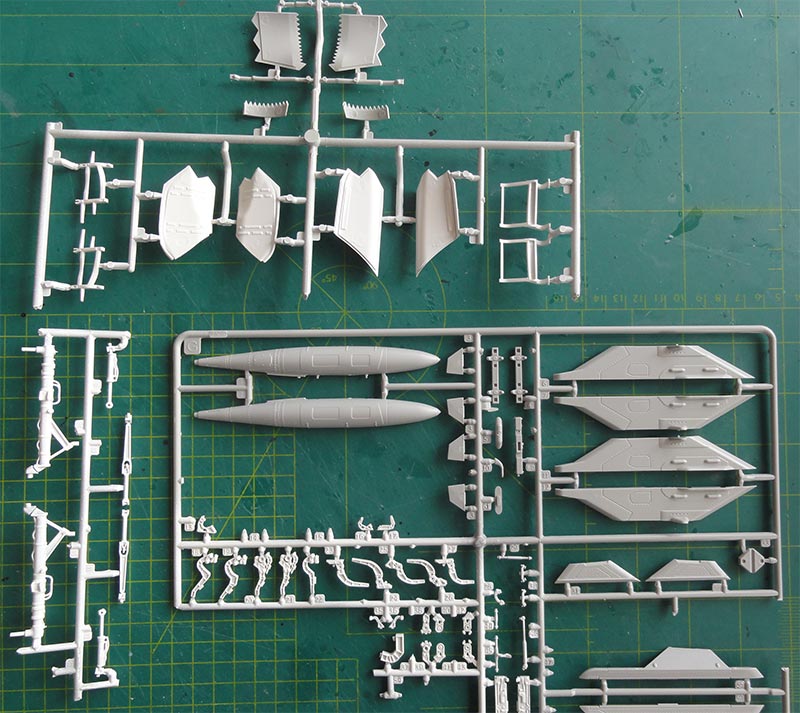

Now some first assemblies were tackled.

Please note that not ALL small panel gaps need filler. For example on the vertical tails, tiny horizontal and a leading edge running gaps are seen on the real F-35 aircraft. So study photos to see what needs filler and what not.

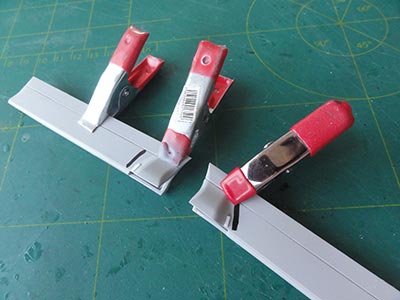

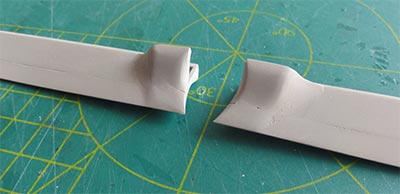

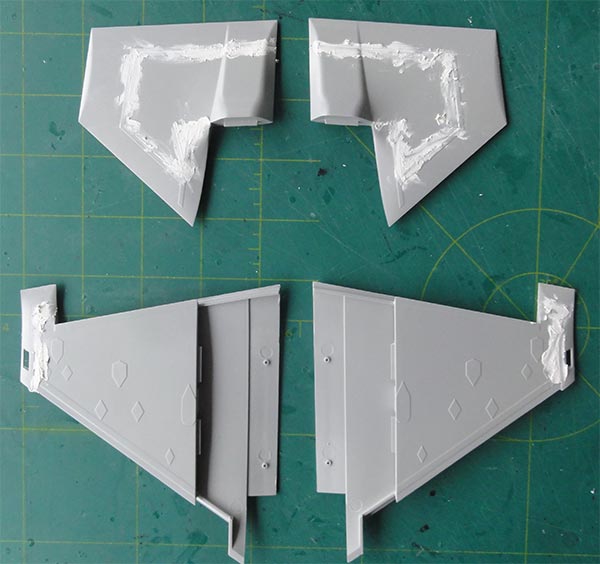

The two large horizontal stabilizers seen in instructions STEP 16 have a better joint when parts #21F and 32F are sanded a bit thinner on their inside areas.

The outboard wing, which sections are remarkably small, neede some filler to fill tiny gaps. On the top of the wing tip some shrinkage was seen. Putty and sanding solves these minor issues.

Wheels and tyres.

The nose wheel tyre seems to be "too much" weighted so I will seek a replacement. The main tyres as well. I will correct these with card and putty. The hubs look fine.

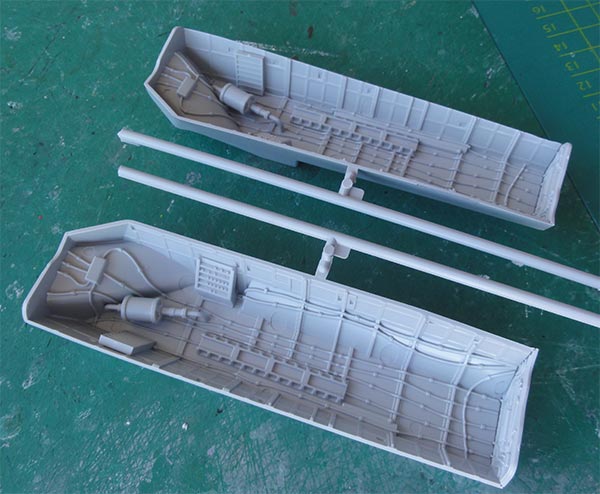

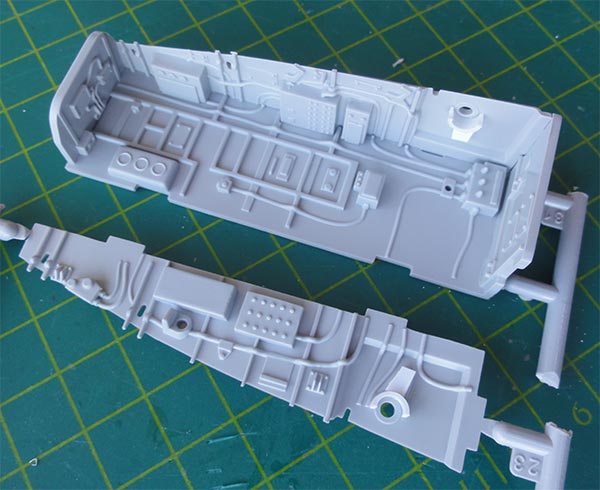

The main weapons bays with rear side and some details as per kit glued in place.

The nose gear bay requires as per instructions STEP 12 that the nose gear is to be installed quite early in the build. I decided to add as few strips to enable fitted the nose gear leg later on. This well strengthen the assembly as well.

Many parts were airbrushed white such as the many door hinges.

On to next [ Page 4... ]

Back to 1/32 Models

(c) Copyright "designer"/ All rights reserved. Your comments are welcomed by webmaster

Created this page

March 31, 2017