Warner AEW of MLD

[ page 2 ]

TBM-3W Warner model kit in 1/32 scale (conversion)

Dutch Naval Air Arm (Marine Luchtvaart Dienst MLD)

...continueing from page 1....

First was now to do some “pre-painting” on the various interior parts.

NOTE: The colour

numbers I could not find on the instructions; these are GUNZE and should

be I think:

H1 black

H2 white

H3 red

H8 aluminium

H9 gold

H13 red ?

H27 Humbrol

63 (brown/yellow)

H33 black ?

H43 green about

Humbrol 116

H61 grey Humbrol

146

H78 mat oliver

drab

H304 olive

drab?

H340 green

about Humbrol 116

The interiors and some other parts were given the appropriate colours with an airbrush or paint brush and some other parts were pre-sprayed while still in their sprues.

(22) Small panel

fit

Some small panels are not fitted,

such as part #F1. Fill the gap between the radar dome and the lower forward

fuselage

All gaps were filled and sanded when

dry. Fill again, sand and repeat as often as necessary.

(23) [T36] Cowling.

Note the supplied metal grills of

the kit are a nice touch. Some more plastic was added to suggest an intake.

Also, some cuts were made in the cowling "flaps" at the rear edge with

a razor saw.

The cowling for this variant has

a straight aft edge (this depends on the particular Avenger plane); add

some thin card to the kit part.

( Do not yet fit the cowling to the

fuselage ).

(24)[T51] Main

assembly

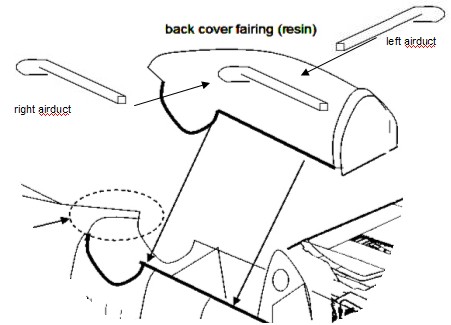

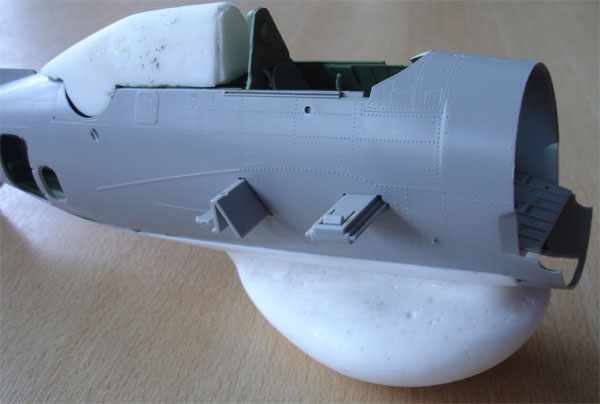

Now it is time to fit the rear resin

back.

NOTE: Do not fit the resin airducts on the Warner back fairing yet before the fit is OK and smooth to prevent damage.

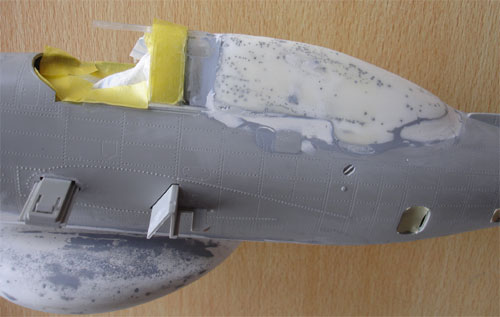

The back resin part was dry fitted.

Some removal of the area at the rear and sanding flat the round edges will

help here. When the fit is reasonable, fit with superglue. Filling the

gaps and sanding smooth is needed to get a flush result. I suggest to use

Scotch tape in the surrounding plastic areas to protect the surfaces from

too many scratches while sanding. The rear end particularly needs some

attention. Fill again, sand and repeat as often as necessary.

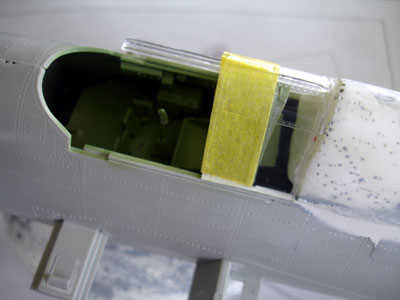

(25) Aft canopy

panel fitting

Fit canopy part K7.

Fill gap with resin rear back part.

Sand flush and paint rear window

portion of K7.

Fill and sand....

Fill and sand...

A first light grey coat revealed

that additional filling and... sanding was needed...

Fit the forward engine cowl and the

pilot instrument coverhood.

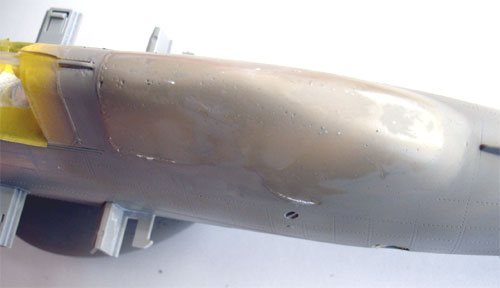

The back fairing seemed OK now, but

still some filling and sanding was needed.

Now the two resin airducts on the

right and left side were fitted. The gaps were filled with white glue or

you can use fine putty.

Note also the thin long strip on

top of the back fairing. Some small intake scoops were also, cut from some

spare bombs from the spares box.

The back area is now ready to get

a couple of coats of grey paint

.

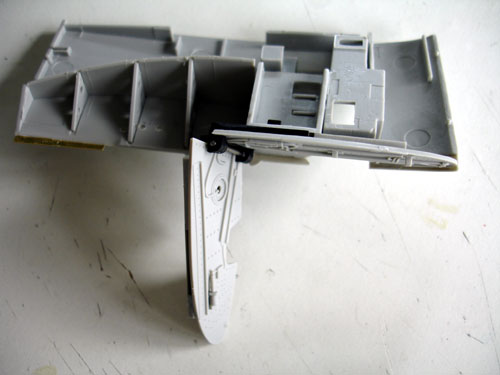

(26-30)[ T37-T44

]

Now fit both wing halves. Some filling

at the wing roots may be needed.

Assemble all as shown. The wing folding

assembly needs some time.

The wing fold mechanism is OK, and

the various parts sprayed white.

The trailing edge flaps would be kept movable; this required filling and sanding the ejector pin marks in their interiors.

The gunports were closed up with filler as these are not present on the TBM-3W Warner and the wing leading edges sanded in profile shape. It was decided to have the wings unfolded in normal horizontal flying position, so all was glued fixed in place. It was decided not to use the metal strips for the wing folding gaps. The parts for the folding mechanisms were used however for strength.

( Please note that the main wing halves are not to be fixed to the model before the complete fuselage ready with all gaps filled and sanded in shape of the radar fit, belly and rear upper fuselage back. )

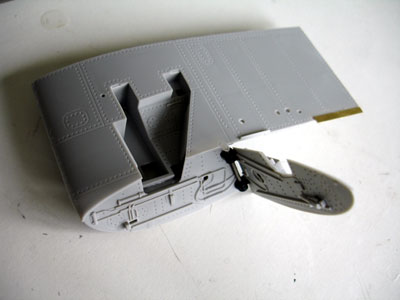

(30-33) [T47-T50]

Assemble the wings as shown and the

fit quite good. The flaps and ailerons were kept movable and are nice touches.

(Leave the engine and cowl for later).

![]()

(36-45) [T51

and next] Main assembly with wing halves, engine and cowling, smaller parts

Assembly some engine parts and fit

engine to bulkhead.

Fit winghalves, fill gaps as needed.

Assembly the gears and stabilizers as shown. To the gearlegs, some hydraulics' tubing was added made from thin metal wire. NOTE: The gear legs were NOT yet added to avoid damage.

Assemble the various smaller parts

like D41, F14, B4 and anti-collision lights.

Also fit the upper wing inspection

panels G16, G17

Fit some smaller airframe parts also at this stage.

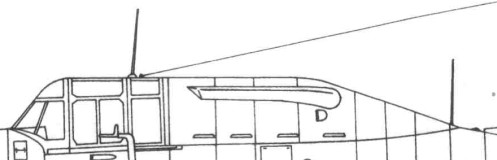

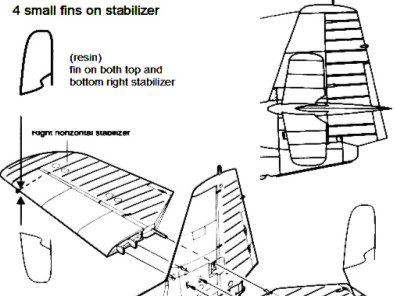

(44) Tailfins

The Warner has four identical fins

fitted on the stabilizer, these are provided in resin. Fill any small gaps

in the fin parts.

The fins can be fitted making sure

they are symmetrical and at the exact spanwise position on the lower and

upper surfaces.

Some putty was needed to fill small holes and also to fit them onto the stabilizer without gaps.

.

.

A peculiar Warner antenna should be fitted on on top of the vertical tail from sprue (leave for later).

(45-48)

Fit various smaller antenna's and

parts.

Fit any wire antenna's later on to

avoid damaging them now. Make these from fishing line.

That's it. Assembly is ready.

![]()

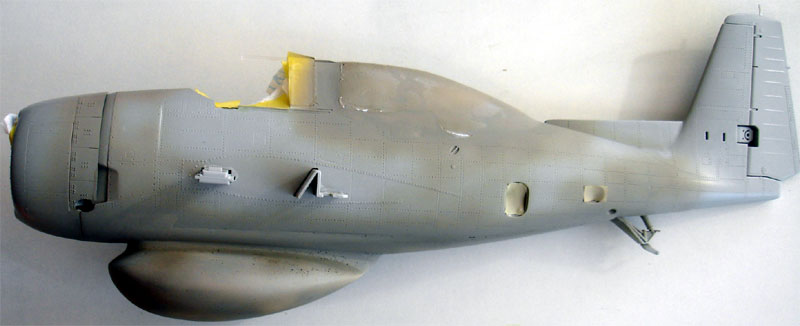

The interior areas were covered with

tape and the overall model was given a first light grey primer coat; this

was applied to check for any flaws in assembly at this stage (Humbrol 64

light grey).

Some areas,"pre-shaded" stripes of

mat black were applied with the airbrush. (You don't need to do this at

this stage however)

The clear areas were protected with

masking tape. The glazing required thus some masking.

Only now to start applying the rest

of the paint scheme.

On to next

[ Page 3... ]

Back to 1/32 scale Models.......

(c) Copyright Meindert "designer"/ All rights reserved. Your comments are welcomed by webmaster