[ Page 2 ]

Grumman A-6A intruder in 1/32 scale kit review & modelling report of the Trumpeter kit

....continued from page 1....

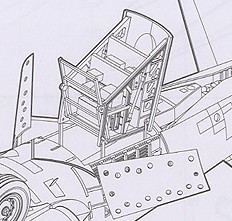

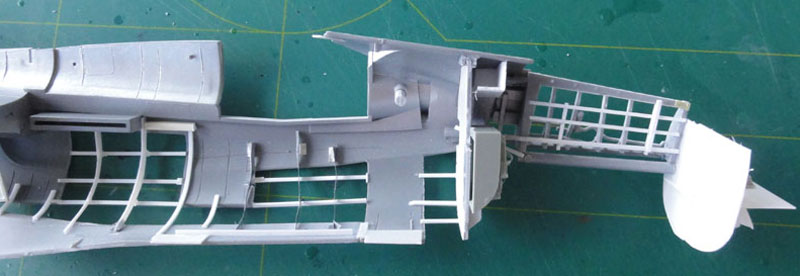

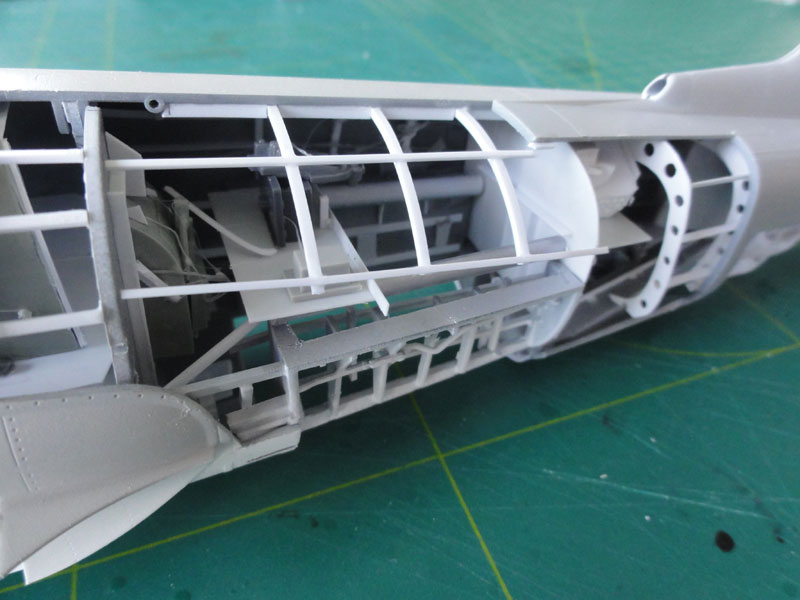

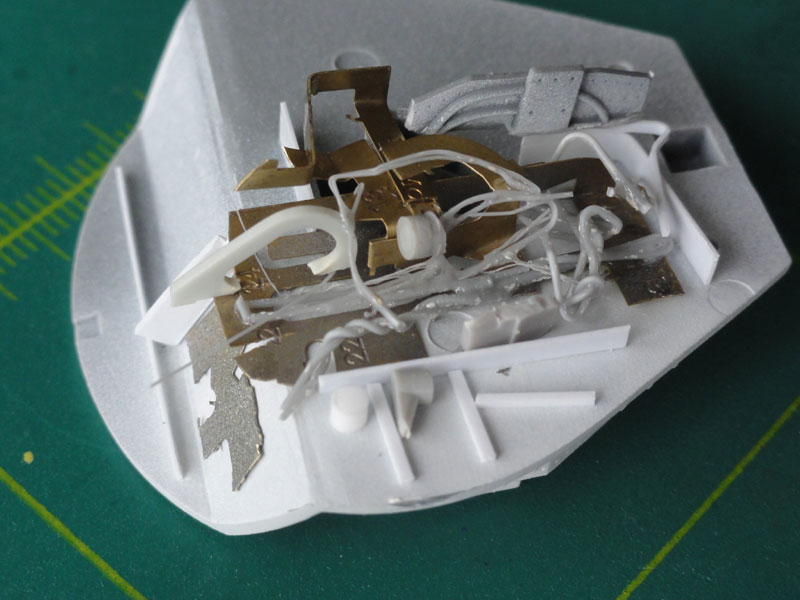

STEP 5

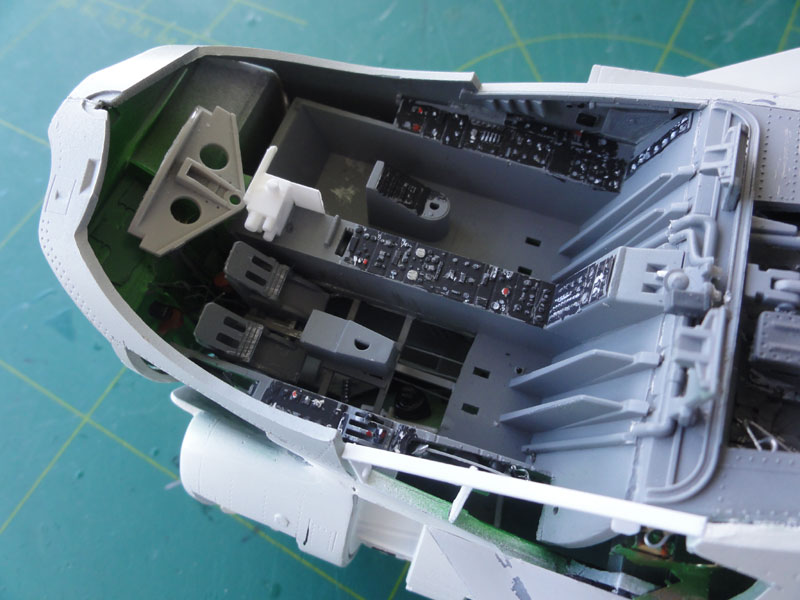

The nice birdcage avionics rack is

in the kit and will be set open. Additional details were added from stretched

sprue, wire etc.

.

.....

.

.....

.

.

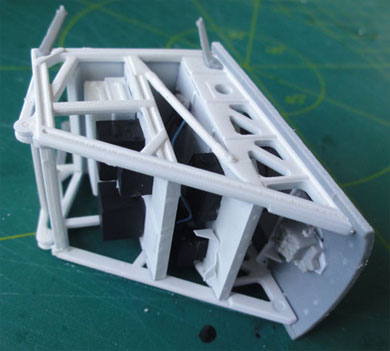

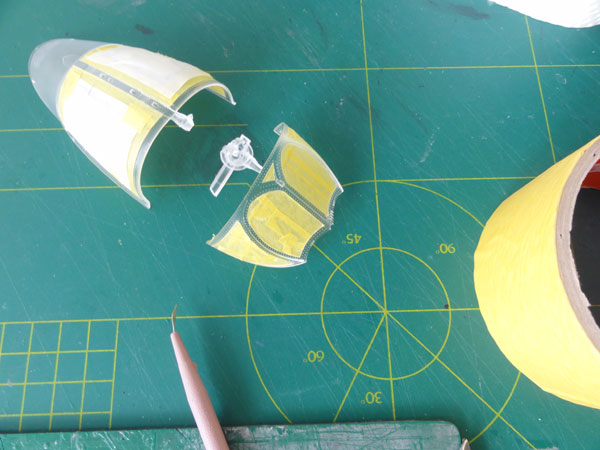

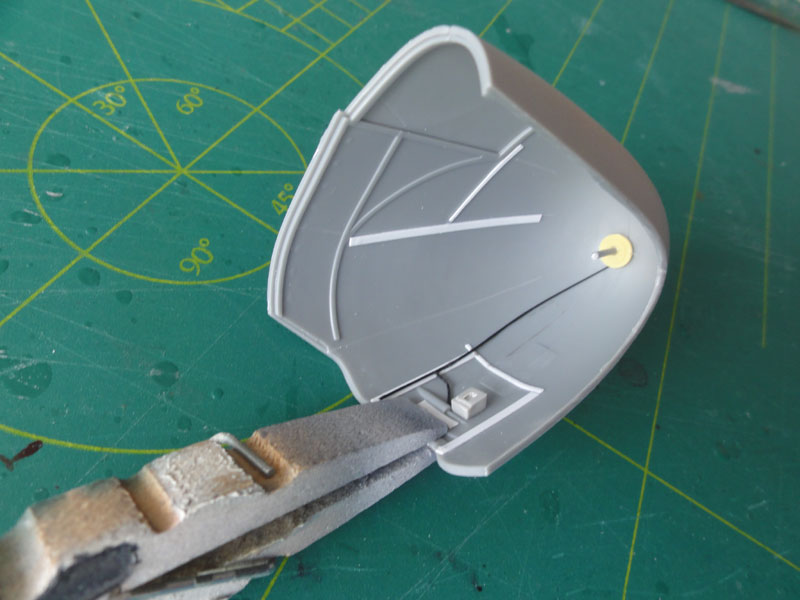

STEPs 8 - 9

The main canopy and windshield are

fine. They were masked with low tack tape and will be airbrushed later

on. PE etched metal mirrors are also in this kit, nicely done.

(STEPs 6-7 and 10 for the undercarriage were discussed on Page 1).

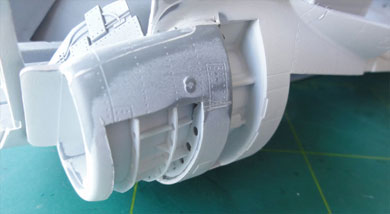

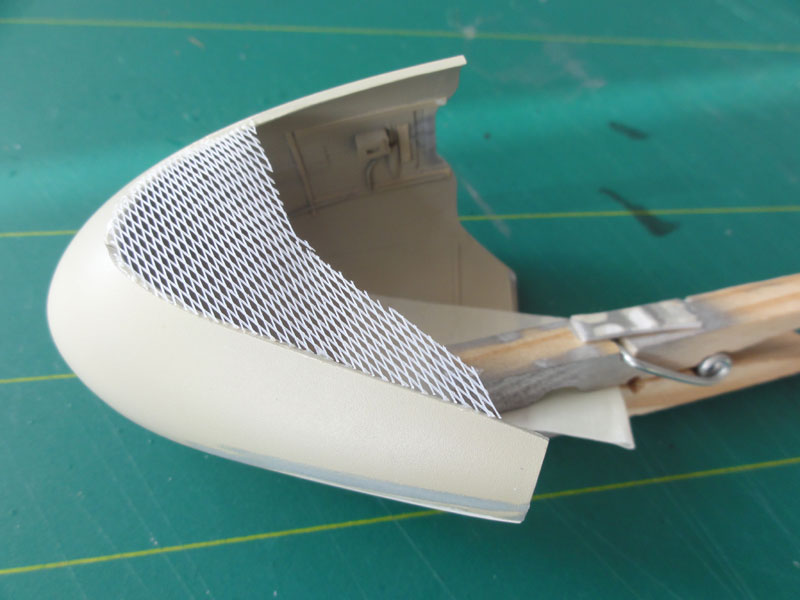

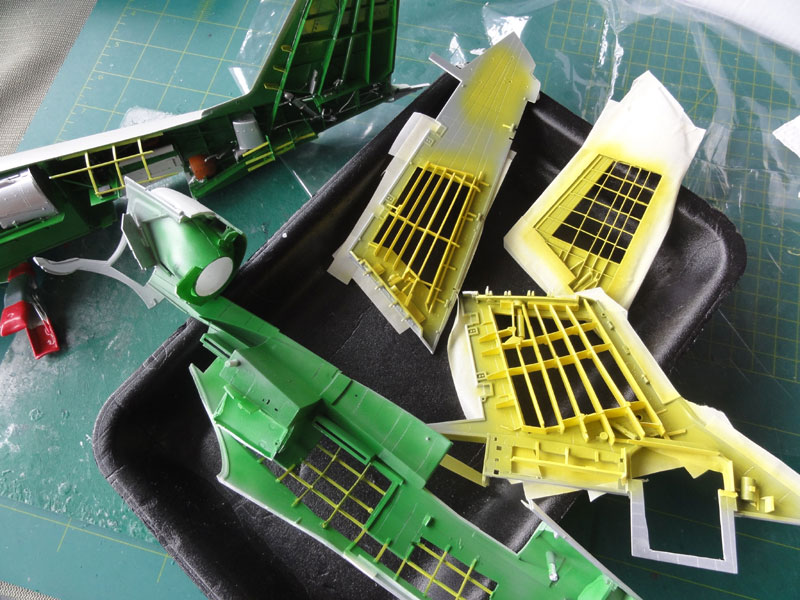

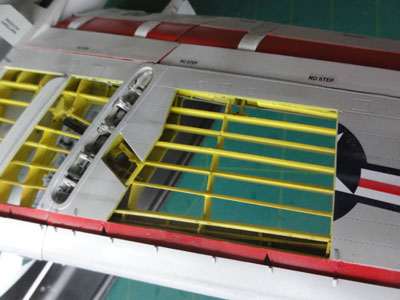

STEPs 11 - 12

One airbrake housing was cut open.

Structural details were added for the "cut away".

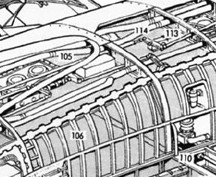

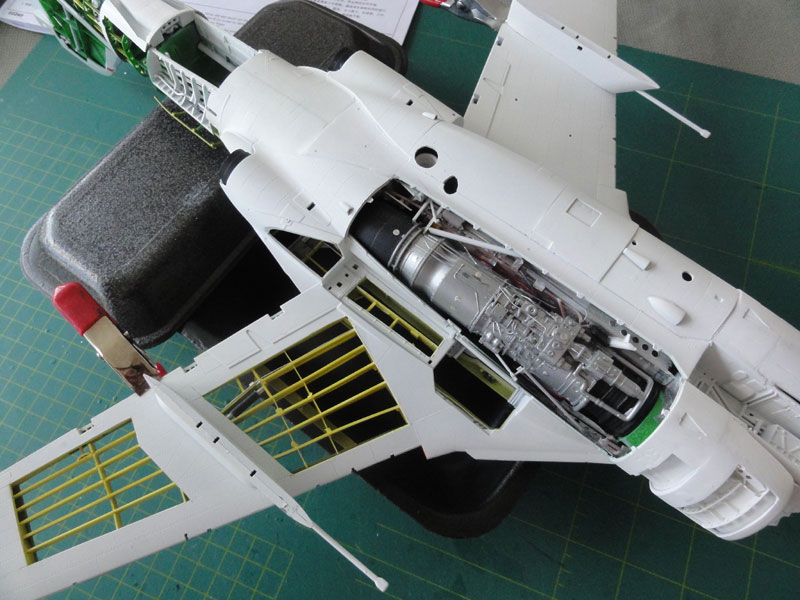

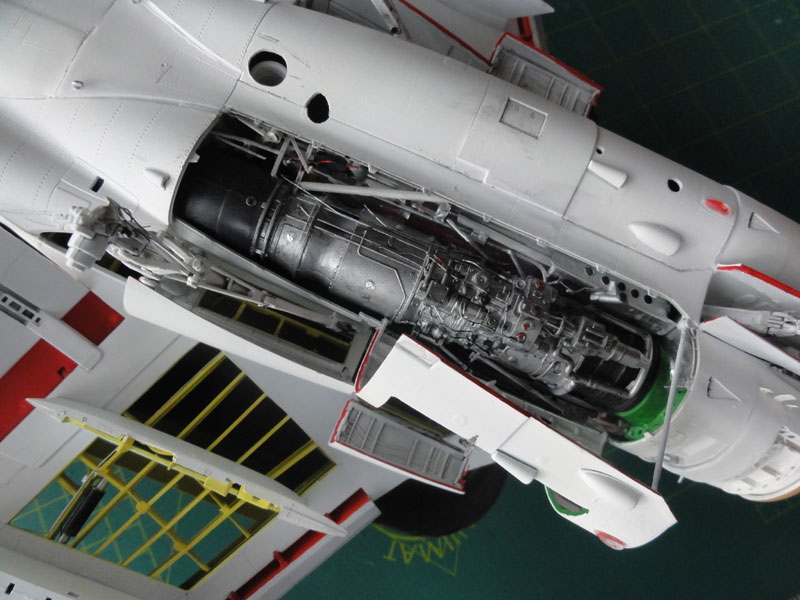

STEP 13

The nose gear was NOT yet set in

place. The major beam and bulkhead is nicely done for the engine bays.

It was not sure of the interior of the engine bay is interior green, so

also some metal aluminium paint was used in places later.

The Left engine bay will be set open

en to be fully detailed later on with rod and sprue. One hatch was also

cut open (part V1 seen in STEP 31).

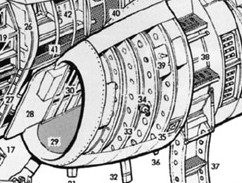

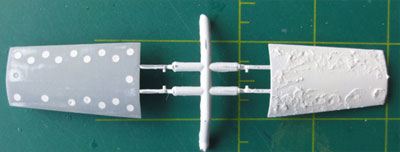

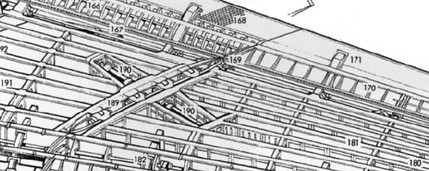

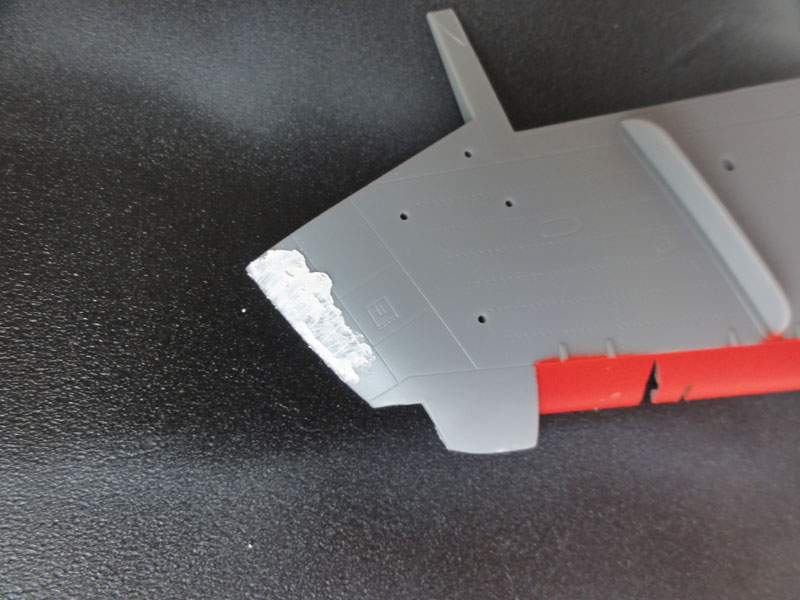

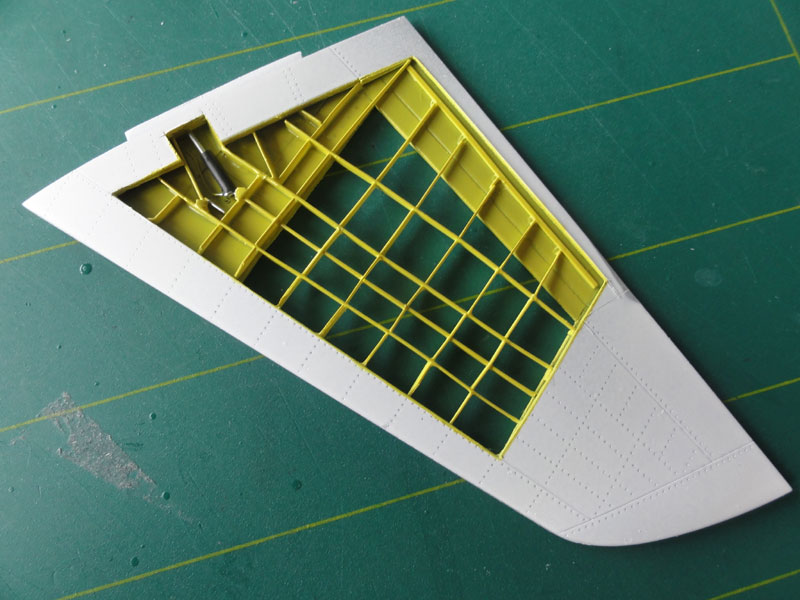

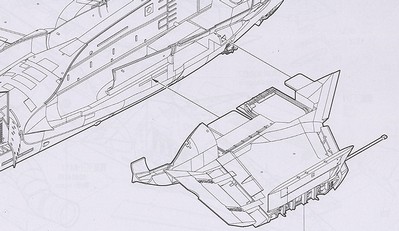

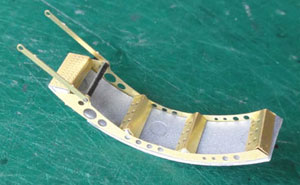

STEPs 14 + 16

The air intakes require minimal filler

and are inside white. Note that in STEP 3 the intake duct length was a

bit extended by 5 mm in the interior. The left intake was opened up for

the cut away and ribs added with weight saving holes. Some photos and

the cut-away drawing were used for reference.

.......

.......

and the adapted kit section....

STEPs 15 + 17

Note that fuselage airspeed spoilers

show variations on a real A-6: no holes, some holes or many holes.

David, a former A-6 pilot, explained...

"the

holes in the speed brakes were required on aircraft that had

operational fuselage brakes. The holes reduced the buffeting caused by

the extended brakes. In the early ‘70s almost all A-6s has the fuselage

brakes deactivated. Some squadrons modified the speedbrake plates and

filled the holes in the thought that drag would be reduced but other

squadrons or intermediate repair depots did not. That explains why one

can see such variations in the speedbrakes as seen in old photos".

So check

photos for your particular model. The US NAVY VA-95 A-6A to be made

through this 1/32 model shows NO HOLES. Thin card was glued inside and

all gaps on the kit parts N3 + N4 filled with putty in this case. (I

normally use white car filler putty of ALABASTINE).

...

... ALABASTINE car filler

ALABASTINE car filler

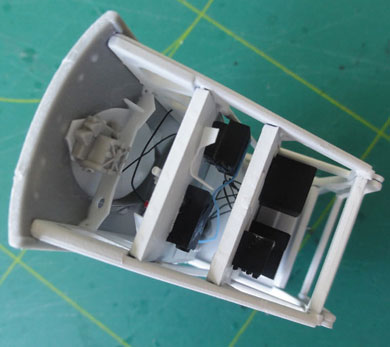

Also the birdcage fit was checked...

but not set in place yet at this stage.

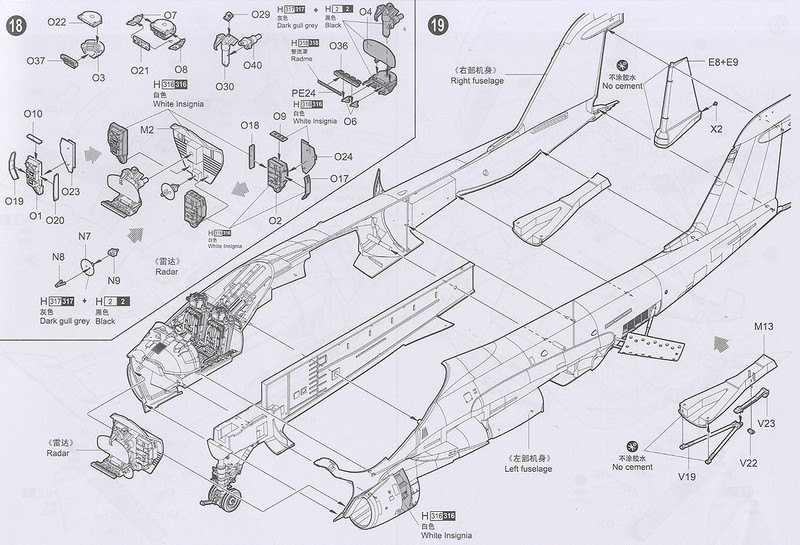

STEP 18

The nose radar details are nicely

done in the kit. The larger A-6A radar is the AN/APQ-88 search- and terrain-

radar and the smaller radar the tracking radar. Only some extra electrical

wiring was added at the back of bulkhead part M2 from stretched sprue as

the nose and some cockpit panels will also be "cut-away".

.

.

The "honeycomb / fiberglass" nose

structure was "cut-away" and made from some wire from a vegetable net and

airbrushed sand/brown. Inside some detail was added from rod. Nose radome

colours varied on Intruders a lot. Here Revell Aqua 36188

Ocker acrylic was used.

STEP 19

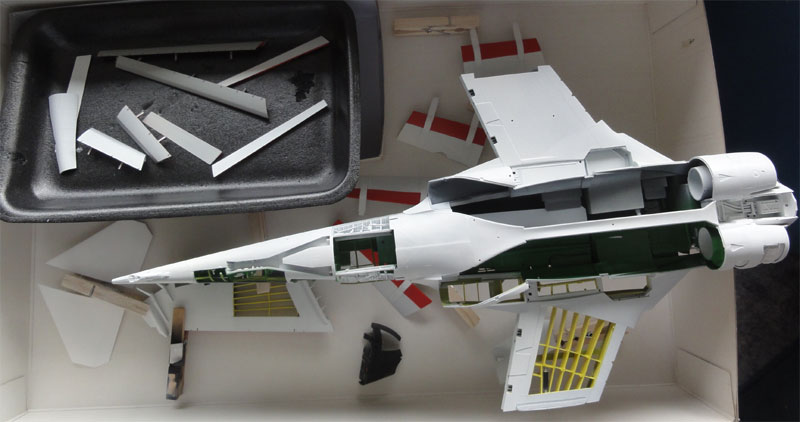

The major assembly was done in some

phases for the fuselage. The tailhook is nicely done in this kit and is

white with black stripes.

NOTE: a nose weight is RECOMMENDED to prevent "tail sitting". Not indicated by Trumpeter!

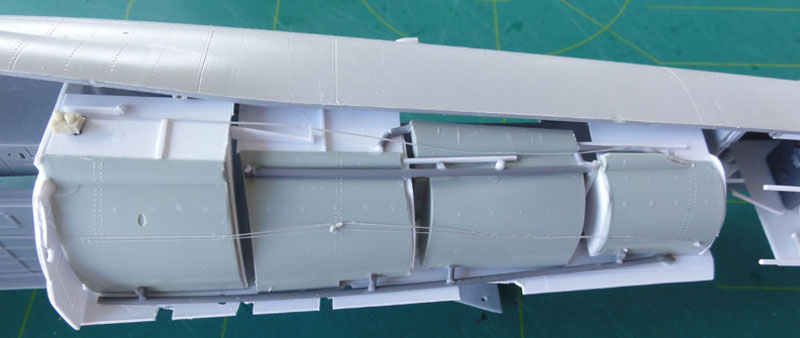

The large central "fuel tanks" inside

the fuselage were made from parts from the spares box and cart.

The fuselage halves were joined. Some

of the cockpit interior is seen after added additional detail. Note the

"cut-away" floor.

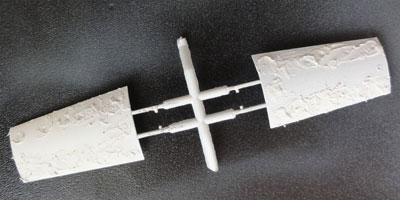

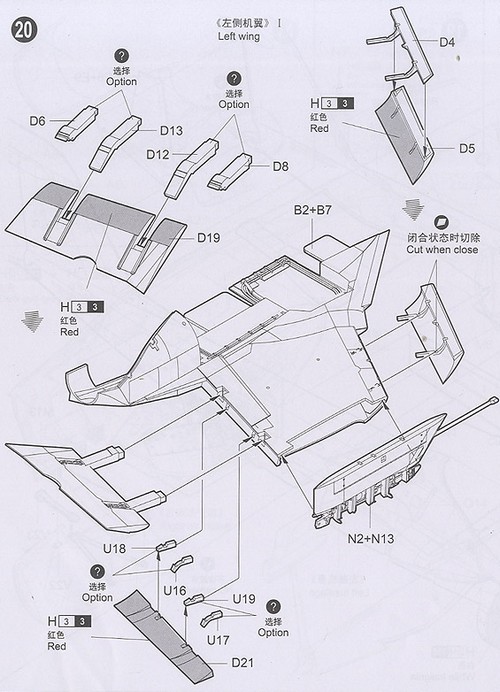

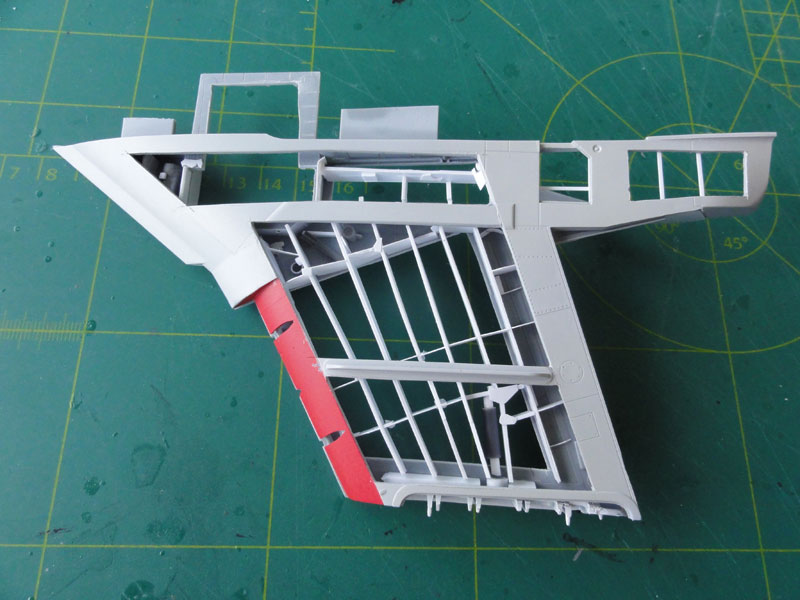

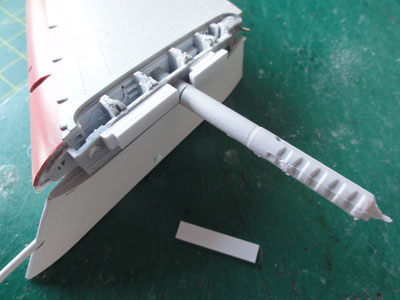

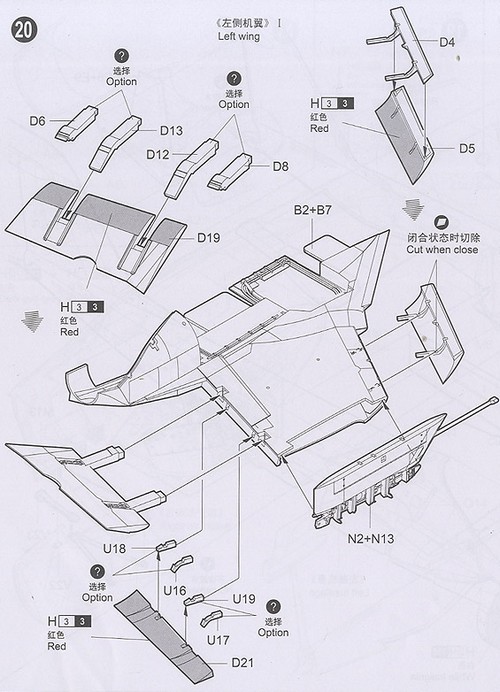

STEPs 20 + 21

The wing is also very nicely done

by Trumpeter with the option to fold the outher wing sections with full

folding mechanism in the kit. For this "cut-away" the wing will be set

unfolded. Also, the flaps can de drooped and slats set extended and the

top wing spoilers are separate parts. The booms extending from the pylons

parts N2+N13 and N1+N6 look OK in length.

.

.

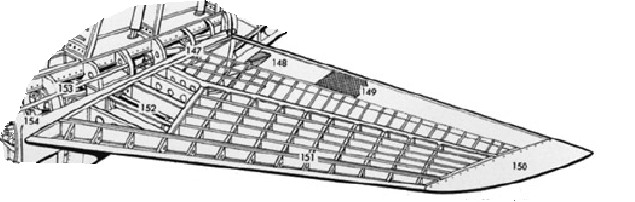

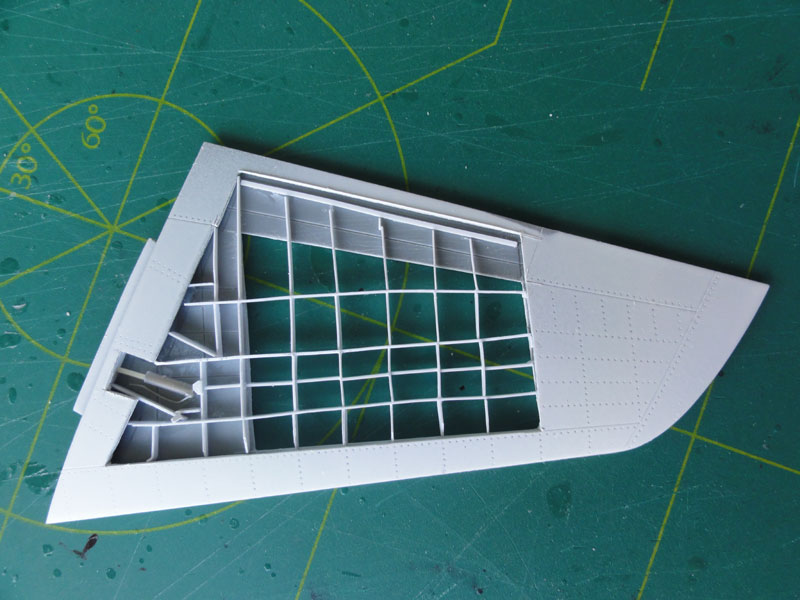

Some LEFT wing halve panels were

already cut-away at an earlier stage. Rib and spar details were added from

plastic rod and card. The folding actuator will also be set in place. All

based on the cut-away drawings used.

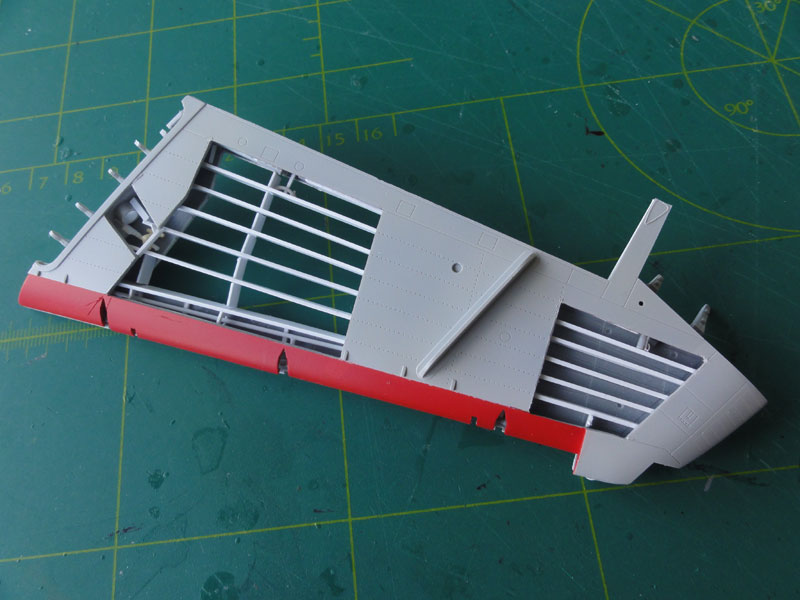

The wing sub-sections were again

airbrushed, work in a step at the time. Lower surfaces are gloss white

(for the old style VA-95 scheme) and upper section FS 36440 gull grey (using

Gunze Sangyo H325). The slat and flap internal areas are RED. Structural

detail still to be airbrushed (yellow) later on.

STEPs 24 - 25

The outher wing panels got a similar

treatment as the central wing panels.

On this A-6A no low visibility lights

were fitted so the engraved panels on the wingtips were filled.

Before installing the wing tip anti-collision

lights, the mating surfaces got a touch up of red (left side) and blue

(right side); (not seen yet here).

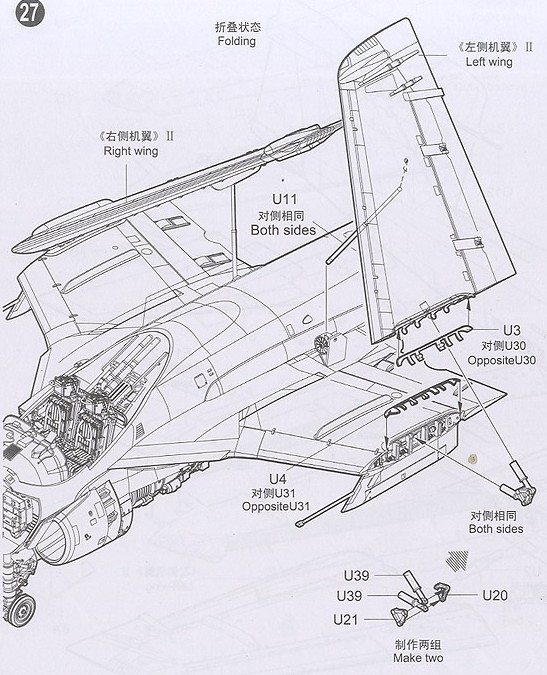

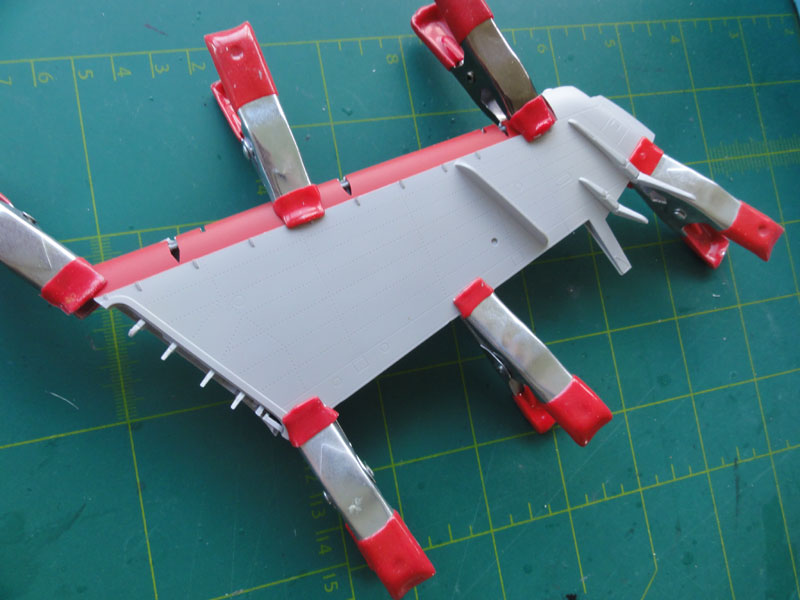

STEPs 26 - 28

The wing was to be set UNFOLDED,

so some additional work was done to strengthen the joints. The kit parts

U2 help here a lot.

.

.

One of the impressive details of this kit is the airflow RAM turbine at the wing root. The A-6A also features a small scoop (Part V6) on the spine, but not on the right cockpit side. I plan to replace the large tail pitot (Part O12) with a thick needle later on.

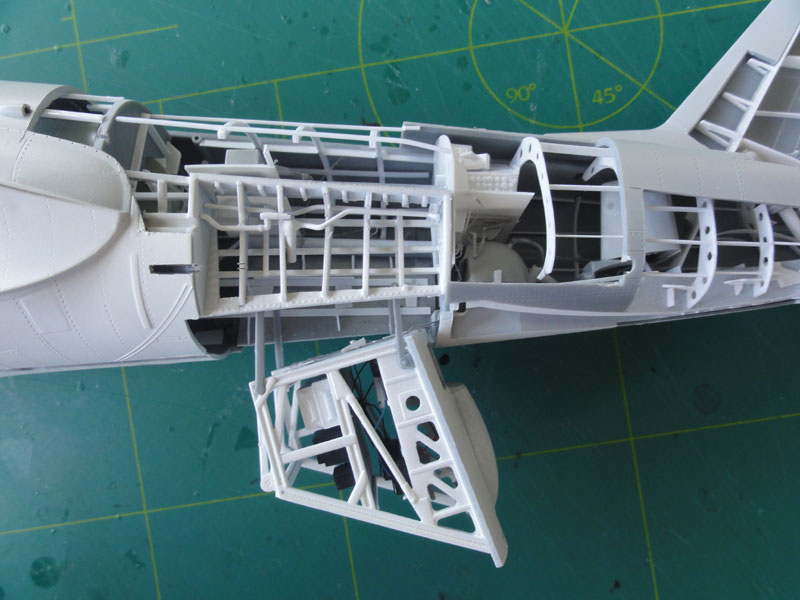

For the left horizontal stabilizer, I cut it open and added structural details according to a cut-away drawing, including ribs and spars.

![]()

All the structural interiors were

given a yellow colour, but that is a personal choice. Yellow used is from

Revell Aqua 36115. The paint on the structure was airbrushed and

requires a lot of masking with low tack tape. Lots and lots of tidious

work sometimes....

The airbrush was used and it is recommended

to thin the Revell Aqua with its own Aqua Color Mix thinner (so not water).

The other interiors were airbrushed "green", using Revell Aqua 36364. Again a personal choice. All the internal details are NOT weathered as obviously they are inside and never exposed to weather!

The horizontal stabilizer was given

an overall white coat and the leading edge an aluminium edge (not yet seen)

with the airbrush.

Attaching the wing center section to the fuselage works OK but needed a tiny amount of filler for the gaps.

STEP 23

To showcase the interior, I cut away an additional panel (Part V1) in the hatch. (not yet seen below).

.

.

STEP 29

The glass windshield and sliding

canopy will be set in place later on. The airframe nose is nicely done

as a separate section. The nose - fuselage gaps were filled with white

glue and after drying, will be painted in the appropriate airframe colour.

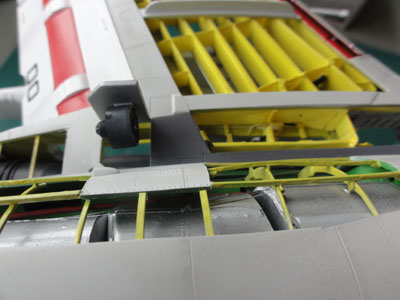

STEPs 30 - 31

Nice are the crew entry steps in

the kit, with some PE parts. The left ladder was set open. Interior is

Red. See also the added cut-away details at the previous

step 14

..

..

The various bays were detailed inside

as needed. This area is for the "birdcage" should stay clear but has avionics

boxes on the sides and rear.

At the lower fuselage, a gap was still

present between the belly and parts V2 + V4. The gap was closed with white

glue. After drying, paint white. Part V9 is an exhaust with a metallic

sheen (not seen here yet). Parts V8 are also to be fitted.

The model will be set on a display

stand. For that purpose a large gap for the display stand of this "cut-away"

model was made in the belly with also a "locking" hole next to it.

.

The trailing edge flaps slats were

now set in place as indicated in STEP 20. It was easier said than done....

The rails (parts D6, D12, D13, D14,

D15 etc) required quite some cutting/trimming to get them fit in place.

Aligning the flaps and getting them symmetrical takes time and work. The

wing tip speed brakes also needed quite some alignment; in the end the

braces ( U12, U13 etc) were sanded flat at the mating surfaces.

Fitting the combined pylon-wing fold

rib (N2-N13) was not easy and needed some trimming as well.

.

.

.

.

STEP 32

The undercarriage legs, which had

already been nicely prepared, were carefully attached using plenty of

thick super glue ("zapp a gap"). Alignment required making the slots

and gaps slightly larger at the location of the bay ceilings. Once the

legs were secure, the edges of the doors were painted with red sealer

using a hand brush before being installed. One of the doors features a

cut-open panel, as seen in the photo:

STEP 33

One left pylon was cut "open" to

show the structure and piping. The outboard pylons were set in place.

On to next [ Page 3.... ]

(c) Copyright Meindert "designer"/ All rights reserved. Your comments are welcomed by webmaster

October 28, 2014