Lockheed Martin F-16B Orange Jumper

[ Page B-2 ]

F-16B conversion of the SUFA Academy kit

... continued from F-16B page B1......

Step 5

The SUFA kit has the appropriate small type F-16 intake as also used for the earlier blocks, like the F-16B.

Also "big mouth" intake parts are still in the sprues, can be dropped into the spares box.

The kit instructions in step 5 are thus OK for the F-16B as well.

Unfortunately

an issue is still there on the intake as such: on the Academy kit the distance

between the intake and the lower fuselage is too small. The RAM intake

and duct are barely visible but should be:

...

...

real

F-16

Academy intake

Also, the earlier block F-16 planes

including the F-16B have also a more visible/prominent small side air

slot lips.

(NOTE: not applicable for the F-16I

SUFA; these planes do not have the air slot). Widening

up the gap and filling/smoothing the RAM intake area is thus needed on

the kit. (NOTE: I did not notice this error on my first F-16 CJ build).

OK, let's fix the problem....

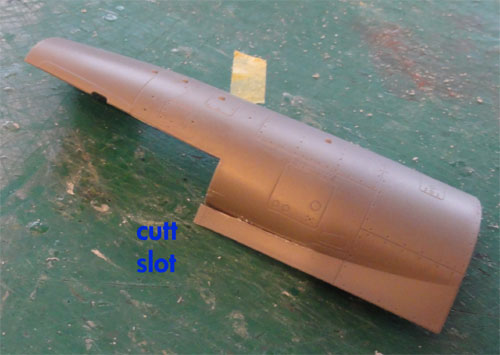

First, simply saw in a slot and bend

the air slot lip. Bend the lip a bit outwards.

The intake was assembled now as per

instructions of step 5.

Nothing spectacular yet.

I recommend not yet to fix the forward

section part D79 to avoid sanding damage still needed.

Tip: the small gaps in the intake

can be filled with "TIPEX" correction fluid.

Next, a section of plastic card was

set on top of the main intake after assembly. This will enlarge the gap

between the intake and the fuselage later on as needed.

Set putty on the lips, let dry and

sand smooth... with here the result...

Now, let's move to the lower fuselage.

Cut out a section of say about 10

mm of the lower fuselage intake area. Make a triangular section of white

plastic card and insert in the area. Sand flush.

Do not yet fit the intake to the lower fuselage! Leave for later.

![]()

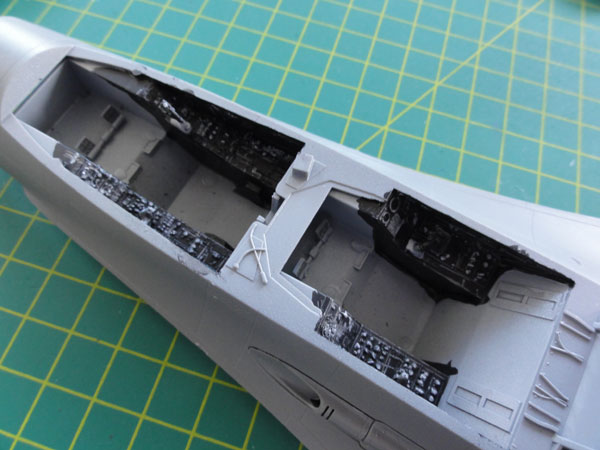

Steps 6-7

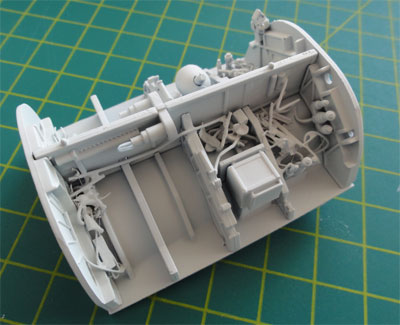

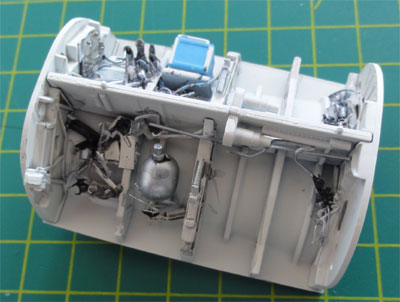

The main gear

bay is OK and similar to the Academy F-16CG/CJ kit,

but can use some extra detail by adding tubing and hydraulics through stretch

sprue and some card. Some effort was put here to get a nice result.

The assembly got a white base coat

and next painted details....

Step 8

The intake

tunnel is a very nice feature as in the first Academy F-16 kit but use

fan part C65 vfor the F-16B.

The rear intake tunnel was simply

assembled. Fit the aft intake on top of the main gear bay section, although

this will make aligning it later on with the forward intake more difficult.

Step 9

The dorsal

SUFA spine with the particular fairings and sensors is not required for

the F-16B. So step 9A is not applicable. Also the parachute housing is

different, look at the vertical fin instructions above

here for the F-16B MLU of the Dutch AF.

Fortunately

Academy F-16I SUFA kit provides an "unused " spare part K17 that

can be used for conventional F-16D two seaters, seen here.... (for future

kit releases?)

This eases the F-16B conversion considerably!!!

The bulkhead part K53 can also be used.

I suggest to leave fixing this fairing

K17 at a later stage after major fuselage assembly.

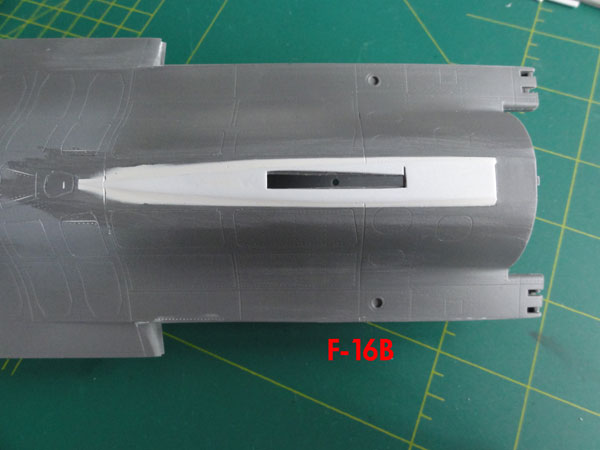

Step 10

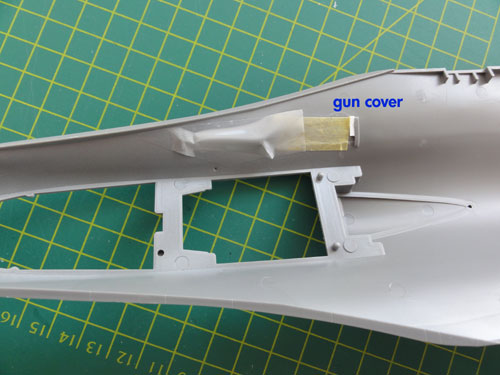

The gun nozzle and fairing is better

now assembled and set in place as it can be better handled now. For the

F-16B I used the kit parts D67 + D68 which seem a little better and finer

than SUFA part K35.

Inside the gun nozzle area,

a piece of tape was set to prevent any see through.

The

rest of the Parts like the conformal fuel tanks (CFT) are not applicable

for early block F-16's like the F-16B, so can be dropped into your spares

box.

Please note that kit instructions

for the ammunition bay are not provided, but the parts of the F-16CJ are

still there should you wish to have this detail in your F-16B model. If

this is desired, cut out the bay panels and add the details. I opted not

to add the internal gun and bay detail. Look

here for the instructions.... .

Step 11

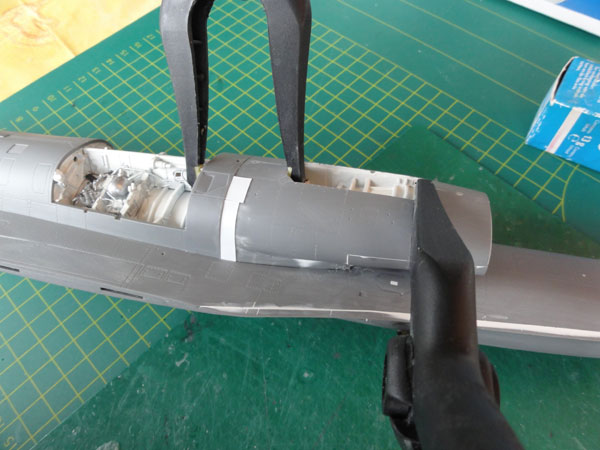

Fitting in the cockpit tub can now

be done. Gaps need some filling with some strengthening rod at the tub.

The lower and

upper fuselage parts are now joined. Take care to carefully align symmetrical

the main gear bay, exactly in the middle.

This is an important stage and will require careful glueing. The end result is that you will find that the fit at the forward fuselage needs filler and some filler at the rear area.

![]()

As the upper and lower fuselage halves

are set aside to dry and to become a stiff assembly.

After 24 hours drying, it is now time to set the prepared intake to the lower forward fuselage.

This requires quite some aligning

and may be some slight removal of material at the edges of the fuselage

intake gap. Force is needed with tape and clamps to close the gap between

all parts.

I could not achieve a flush assembly,

leave for a couple of hours to dry. Some thin card and putty is now

needed and followed by sanding to get a good result. This takes some

effort, but do it now as the model can now easily be handled.

Sanding and filling is needed a couple of times here.

![]()

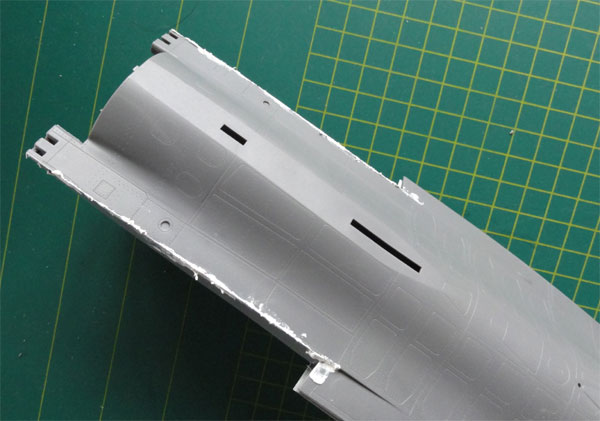

As noted

before, the older block F-16's like the F-16B have the original thin base

vertical tail. The tail was already prepared as seen

here on page 1.

Now it is time to adapt the rear

fuselage joint. This needs a curved area to be added to fill the flat area

of the "thick base" Academy kit tail.

First, a section of 0,5 mm card was

shaped and added on top op the rear fuselage joint area. Note the opened

slot to accept the Hasegawa tail stab for a stronger joint.

Then, the curve was achieved by filling

and sanding.

.. with the results...

The vertical tail itself will be

set later after main wings are set onto the fuselage.

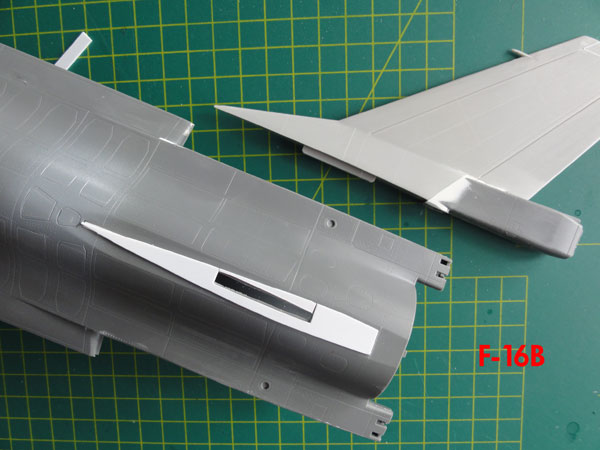

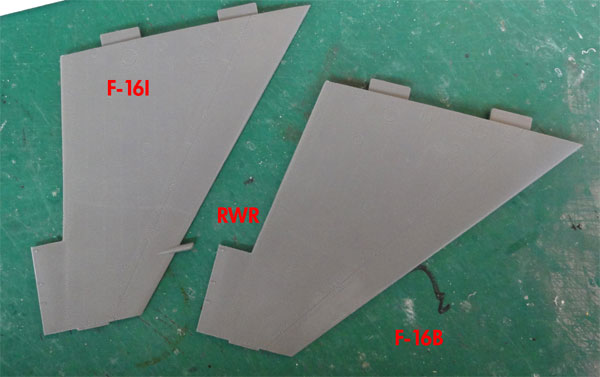

Steps 18-19

The wing assembly

is as on the Academy F-16CG/CJ kit. But for the F-16B, the moulded

leading edge RWR receivers are NOT

needed, so cut-off, sand in airfoil shape to have a straight clean leading

edge.

The Parts B13

for the static dischargers; these are best replaced with thin electric

wire.

Please note

that the strength of the wing joint-fuselage is very weak, so make a strong

joint with lots of glue.

Filler and sanding is needed here

as well.

In step 19 I

had some trouble here with the radar absorbing panels parts PE5-9 provided

as etched metal with the kit. These are aft of the trailing edge and at

the stabilizer rotation points. To get a good flush fit is quite difficult.

Take some time to do it, I found out later....

(c) Copyright "designer"/ All rights reserved. Your comments are welcomed by webmaster

Created this page

November 27, 2010