F-4EJ Phantom II

[ page 2 ]

Tamiya F-4EJ model kit in 1/32 scale

JASDF Japan

..... continued from previous page 1....

A step by step approach will be given and depending on the type of work, will not follow the kit steps. The kit step # will be indicated however.

[ Step 0 ] :

Overall preparations

The kit has various "re-inforcement

plates" on many surfaces (note: these are NOT battle damage repare plates!

Phantoms received various structural re-inforcements during their service

careers and also on certain variants, the F-4EJ being no exception).

For the F-4EJ not all plates

should be there and some of them are too pronounced on the kit parts.

Start with the main fuselage part and sand off the plates at the mid fuselage and rear fuselage . Also sand off the plates at intakes parts A1+A2. On the wing tips, the plate at the upper leading edge should be sanded off (so flush) and I suggest to reduce some thickness on the mid hinge re-inforcement plate (parts A4 + A8).

Next....

- First fit the panel A7 as seen

in step 1 and sand flush (as the F-4EJ has indeed no refuelling boom).

- Also fit part A3 as seen in Step

2, fill and sand smooth.

- A small draining hole is missing

on both sides of the fuselage above the root of the wing leading - edge.

Make a hole with a 0.2 mm drill.

- Also, drill two holes in the spine

(suggesting the refuelling indicator lights) in the round panel in front

of part A3 with 0,3 mm.

- Fill the RAM air turbine panel

lines with putty on left fuselage in center of walkway (not on the F-4EJ)

as well the corresponding panel on the right side.

[ Step 1 ]:

Intakes

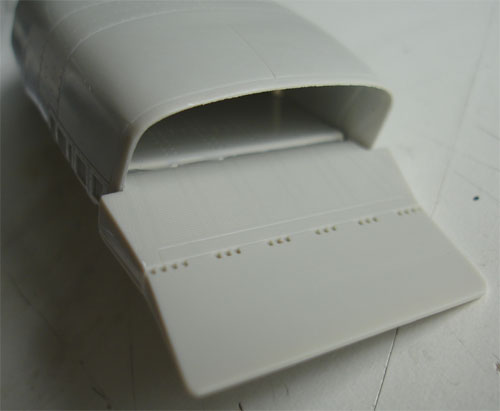

The intake as provided in the kit

gives problems because when you look inside it, you see edges as the intake

lips do not match the intake tunnels/ducts. You can repair this with some

effort (alternatively buy aftermarket resin "Seamless suckers intakes").

Repair requires some cutting and

sawing but can be done:

a. Separate the two forward intake

ducts as moulded on the main fuselage with a razor saw; use caution and

try to saw in a straight lines.

b. Assemble the ducts (parts B26+B42,

B27+B43); do not fit the compressor parts yet.

c. Fit the sawed off plastic ducts

onto the assembled ducts

d. Dry fit the whole assembly and

carefully determine where to fit the outward intakes A1 and A2

e. Make an assembly as seen below

f. Using Milliput, make the internal

edges invisible. This may take some layers.

g. Continue with the splitter plates: they have some vents at the lower and upper rear ends. Cut open and add some tiny walls from card. The ramp inboard edge is indeed correctly angled down in the kit. Assemble the splitter plate parts and fill the rear with putty; sand flush after drying.

h. Spray the entire ducts matt white as you are unable to reach them with the airbrush later on. Also spray on white paint at the rear flat panel on the splitter plates.

i. Glue on the splitter plates onto

the prepared intakes and make sure they are well aligned with the main

fuselage.

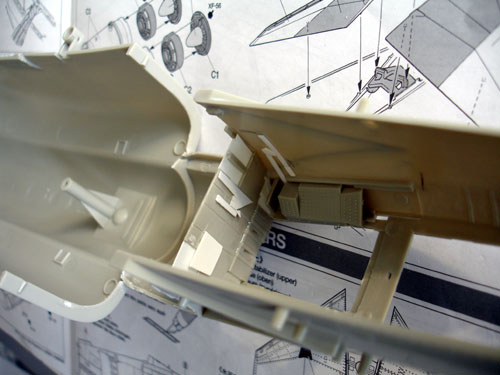

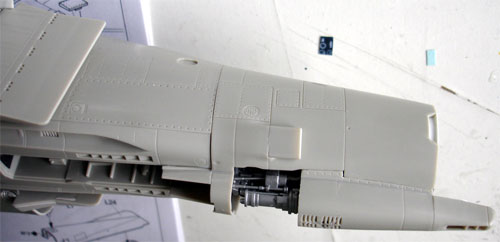

Here you see the whole intake assembly,

being much better now.

![]()

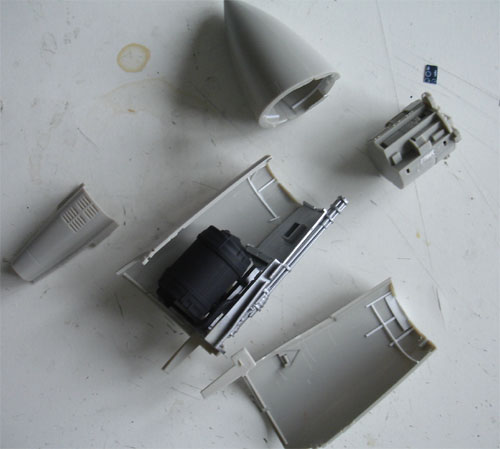

[ Step 2 ]: leave for later, go to...

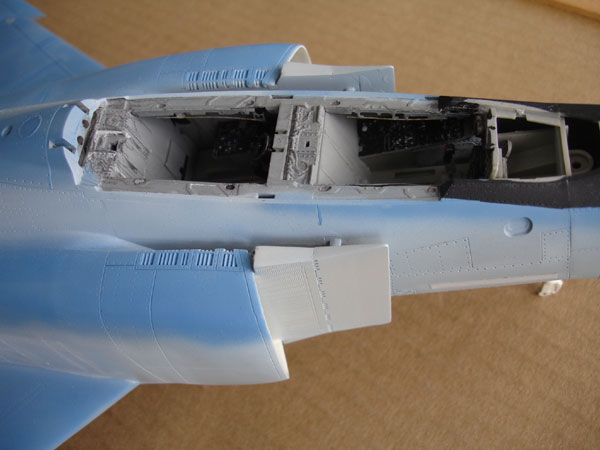

[ Steps 3- 4

]: Cockpit

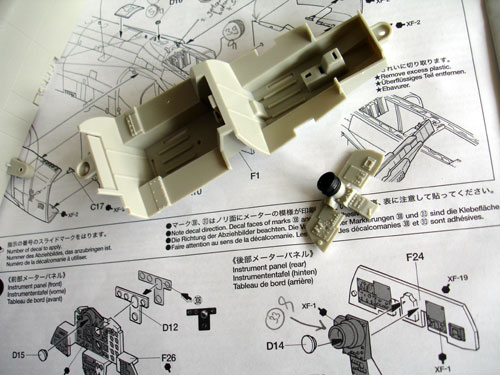

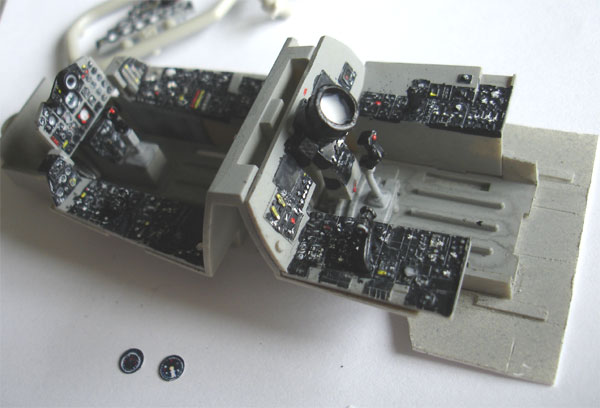

Tamiya provides for the F-4EJ correct

instrument panels (with new parts). The details are raised with knobs and

edges and very good. With some painting you can get fine results. There

are however some small errors in the Tamiya cockpit parts which can easily

be corrected:

a. the scope on part F30 is too small

in diameter. Cut off and replace.

b. the rear bulkhead wall of part

F4 should be vertical and not angled (error in all Tamiya F-4 kits).

c. the side consoles in the back

cockpit of the F-4E do not go all the way to the back. There are shelves

with equipment to be fitted. So remove some plastic as seen below and add

a floor and new bulkhead. (The top edge of the bulkhead should remain at

the same station position.)

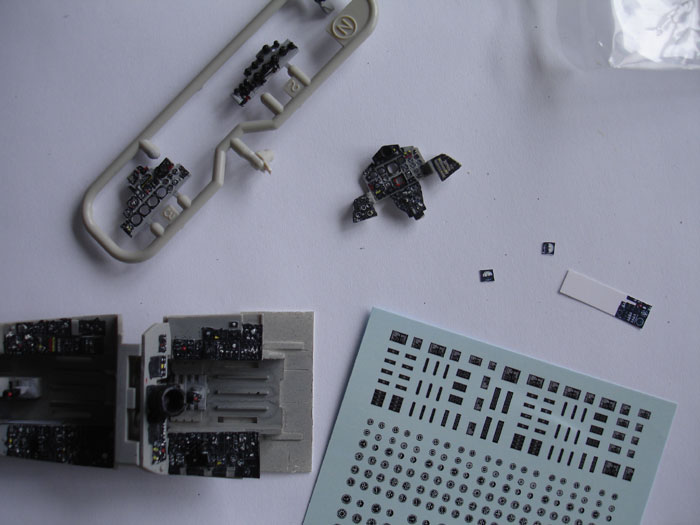

Obviously you can add more details

in the cockpit and for this model Eduard set 32-041

for the F-4E is also used to add

some extra etched metal detailling.

The tub was sprayed light grey. (note:

the missing shelves with equipment will be fitted later on).

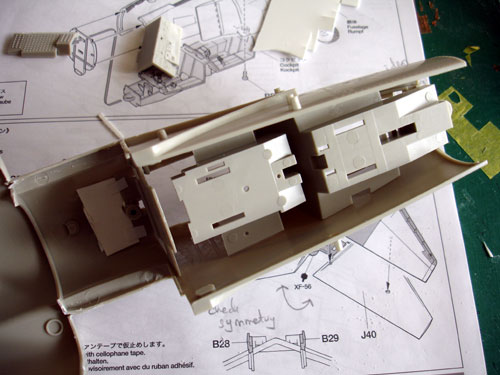

The area at the rear canopy hinge

also cries for some extra details and there is an opening. This was

also drilled open and a horizontal floor inside the spine fitted as seen

below with the tub dry-fitted.

The inner walls of the cockpit got

extra details from card, stretched sprue using also some Eduard metal details.

Below you see also the fuse panel part A10 also fitted.

The canopy hooks fit into lock openings

in the horizontal sides. These were drilled open.

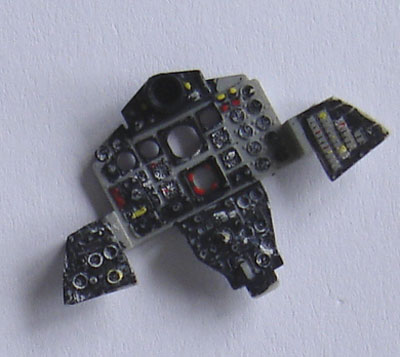

The instrument panels themselves got

the usual treatment with painting with a very fine tip brush, drybrushing,

scratching in the dials and using instrument decals is some areas.

The cockpit also got additional details

painted on and some sprue.

The instrument decals are from an

"unknown" decal source. Add these dials and instruments, using a Waldron

Punch and Dy set to punch them out.

Step 5 was left for later as the cockpit tub would be fitted later

[ Step 6 ]

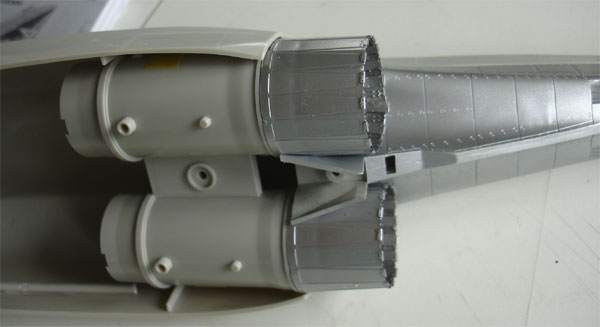

Assemble the exhaust pipes after

spraying them metallic black. The gap between the two halves was filled

with white glue. A final coat of metallic black was sprayed on.

The stabilizer was also assembled,

some minor putty was needed at their tips.

Steps 7 + 8 with the rear fuselage area were skipped for later.

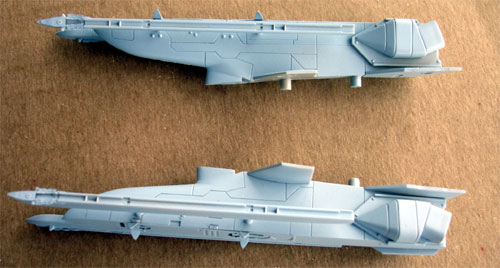

[ Step 9 ]

The Tamiya tail pipes parts #C11 are

too small in diameter at their ends. It was decided to insert a triangle

shaped piece of plastic card as seen below. Simply make an insert cut starting

at the edge but do NOT make a cut at the entire length of the part in order

to keep some strength here. .

Insert the card and glue firmly in

place.

.

.

Next, the Eduard

set etched metal details for the jet exhaust were added, fortunately you

get some extra parts in order to cover the entire larger exhaust internal

areas with the larger diameter.

note

the small Eduard parts

The exhaust cone was "loosely fitted"

in place with the metal screws. The tailhook will be added later on.

The small plastic inserts #L6 + #L7

were added (on Tamiya F-4 Naval kits you will get catapult launch hooks).

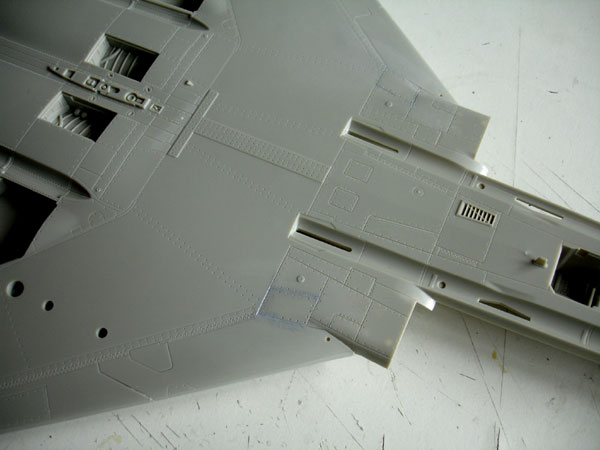

[ Steps 10 and

11 ]

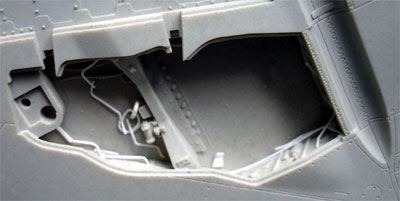

The wheel bays were OK, and assembled.

Some extra detail was added with stretched sprue in the bays to suggest

hydraulic pipes and tubes.

The F-4EJ has no inboard slats,

so the inboard panel lines on parts #A13 + #A14 were filled with putty

(note these are very fine lines).

The auxiliary intake doors on the

lower mid fuselage were OK, the bay was not further "deepened". The overall

result will look OK.

An important next action is....

The overall model parts with its wings were assembled. Take care to make the gap at the wing-fuselage junction as small as possible. For that purpose, a "spacer" made of thick plastic sprue was made and used to keep the fuselage walls are correct distance.

It was also required to fit the horizontal stabilzers, although they are quite vulnerable to handling later on. Also, the "metall" exhaust part from Step 7 was fitted.

![]()

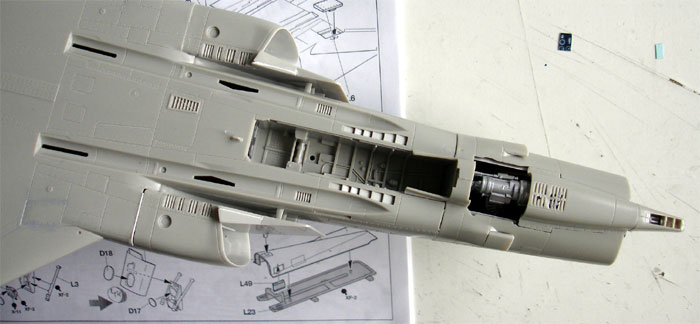

It was decided to show the canon

as provided in the kit. The access panel would be set open. With a razor

saw the lower panel was separated. The canon fairing grills on part were

opened up with an X-acto knife.

[ Steps 12

and 13]

The canon was assembled as shown

and is well detailed. Inside the fuselage some details were added with

rod and sprue.

Another view of the canon....

[ Steps 14 and

15 ]

It was also decided to shown the

radarcone open. You get a clear transparant section in the kit and a 'solid"

section. The solid parts were used, and the radar nose cutt off with a

razor saw.

Also, the radar and its equipment

is provided in the kit and well represented. The radar disk #L42 will be

replaced however later on with a part of mesh with opened holes.

Inside the radar cone, some extra

detail was added with sprue and card.

The view with the canon and separate

radar nose.

[ Steps 16 and

17 ]

The canon nozzle is for the F-4EJ

and correct.

The nose gear leg was assembled as per instructions. You get an metal leg as basis. Some Eduard details were added to the gears. The leg was not yet fixed on the model.

[ Steps 18 and

19 ]

The nose gear and details like the

doors are excellent. The doors will be fitted after the whole assembly

and painting of the model.

[ Step 28 ] Vertical tail

The vertical tail is OK, but remove a couple of millimeters of plastic at the lip of parts L39+L40, this will improve their fit on top.

Fit the fit onto the fuselage spin and align carefully. The base intake Part L51 could use a little refinement with a sanding stick to make it finer.

The whole model was checked for small gaps and puttied. The cockpit openings were closed with Scotch tape. Adding putty in areas, fill up any gaps and flaws. You can remove putty with nail polish remover without damaging the surfaces as no sanding is needed. Only in areas where you need some "built-up" putty, sanding is appropriate.

After removal

of the putty and polishing the model, it was given a light grey base coat.

This revealed eg. that the intake splitter plates needed some extra filler

as seen below...

.

.

Also at the gun area some work was

needed.

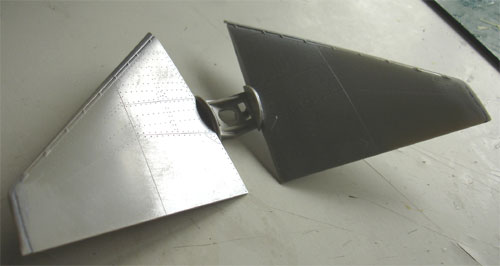

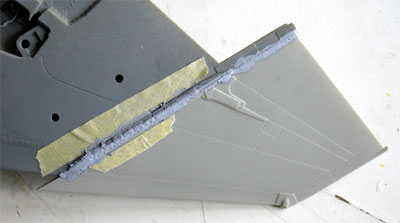

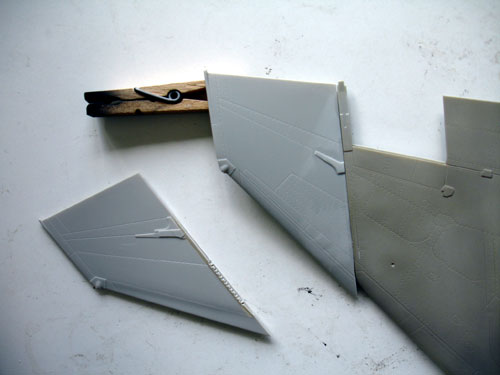

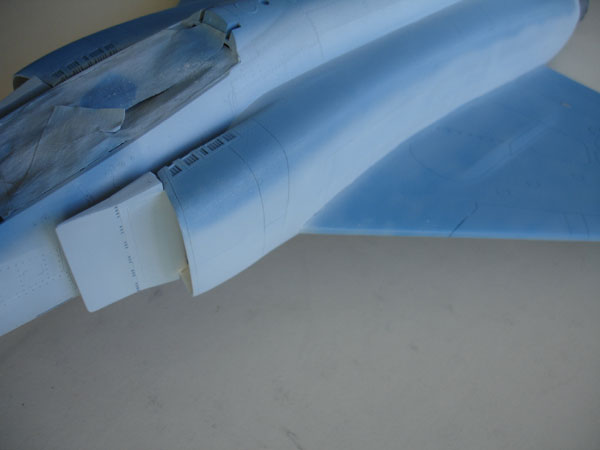

[ Steps 29 +

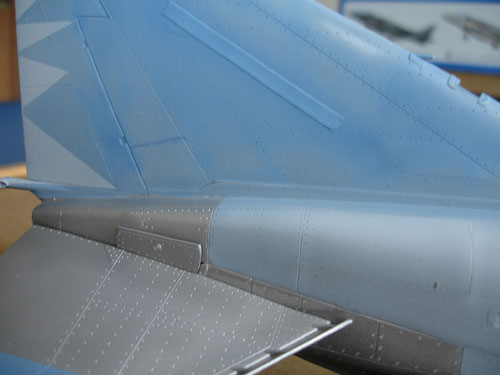

30 ] Wing tips

Next the wing tips are to be added.

First, sand off completely the thick "plates" at the leading edges of the

wing tips (parts A4, A8 ) and also reduce the thickness a bit of the plate

at the hinge itself.

Please note that the "tilt angle"

as moulded on the wing tip of the Tamiya kit is much too large! It

should be 13 degrees and not 24 degrees ! This was corrected with the reduced

angle. Some sanding and work is needed to fill up the resulting gap. Also

putty is needed.

.

.

Work in progress on the tips.

These tip corrections will vastly

improve the look of the F-4 model.

(The trailing edge flaps were not

yet set onto the model).

The main gear legs are not 100% correct, but good enough. The metal legs of the kit will benefit if they get extra details using the Eduard set. The anti-torque rods were replaced etc.

[ Step 21 ] Lower fuselage area

The wheelbays were detailed with sprue and rod as the kit bays are a bit bare.

.

.

Also, the nose wheel bay on a real F-4 has quite some tubing and wiring! Seen here are the added details. The nose leg was fitted first before adding details.

.

.

.

.

[ Step 33 ] Canopies

The kit canopy frames would greatly benefit from adding details and the Eduard set comes in handy here. take care when removing the transparant parts from their sprues! Use a fine razor saw.

Note that F-4 has mirrors fitted inside the canopies.

Now, the entire model was given again of light grey coat (Humbrol 127 enamel) with the airbrush to get a smooth surface.

.

.

.

This shows that the finish is OK now.

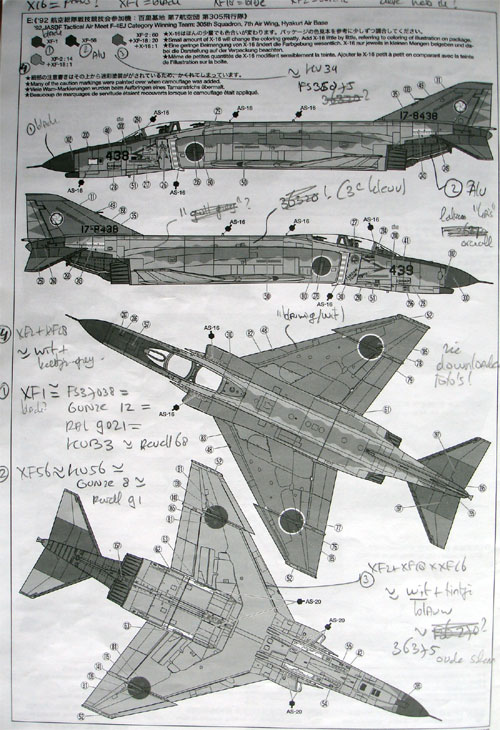

You may be wondering why it took so long to continue with this kit. Well actually it was the choice of colours and scheme for a nice Japanese F-4EJ. I was fascinated by the built of the smaller 1/72 F-4EJ of Fujimi and liked the scheme. This meant I had to make my own decals of this same scheme. I did but at the end I saw some very nice blueish schemes as wel.

I could not figure out what good colours where as Tamiya does only indicate a mix of their own acrylics. I could not find as Fed.Std equivalents, despite some very colourfull Japanese books and searches on Internet. So the built of this model was halted for a few years!

So after some time, looking at the kit decals and all stencilling supplied I decided to go for a scheme as in the kit. Picked was scheme no. E for a JASDF no.305 squadron plane ofJapanese Air Self Defense Force at Hyakuri Air Base.

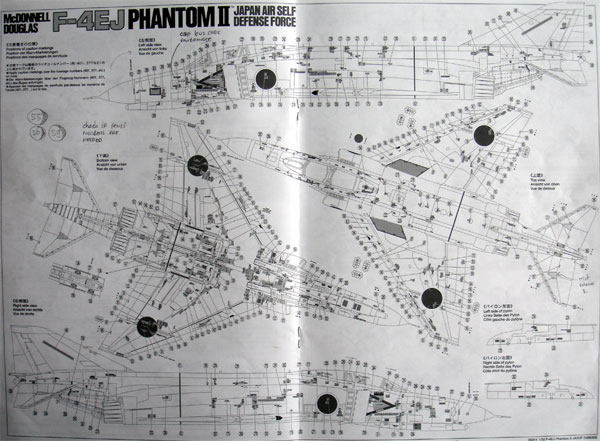

The box-art seen here. You get lots of stencils in the kit, the instructions are seen below....

With the 305 squadron plane paint scheme.. see all my notes on possible colours... I selected the Tamiya mixed colours in the end.

X-16

XF-18

These colours were mixed as on page

22 of the Tamiya kit instructions using these:

TAMIYA XF-18 is a blue colour, XF-2

= white, and X-16 is purple!

Other usual colours are XF-1 black

and XF-56 aluminium.

You will need to thin with Tamiya

thinner as well.

Not an easy task to mix these colours but on the other hand the real planes show large wear with various hues and shines. I came to the conclusion that the lower areas are white with a blue hue and the upper colours have patterns of a darker blue/purple mix.

Make larger paint quantities for re-touching the paint later on, otherwise you are unable to match the colour exactly. Also spray some spare clear decals in these colours for patch work later on if needed.

![]()

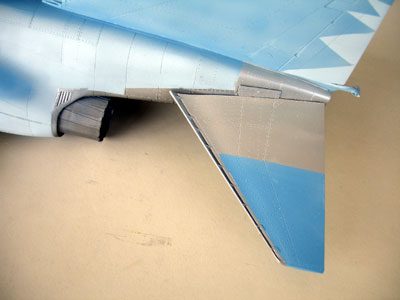

First, a pre-shade

was done with black on panellines and recesses etc. Next, the intakes

were sprayed white. When dry, these were masked of with paper tissue and

tape.

main gear bay with some added details

Starting with the lower surfaces and the upper light colour "white/blue" the model was sprayed with my Steinbeck airbrush, using the largest needle. Do not forget to spray on the low visibility light stickers as well... I forgot and had to do that later.

Than, the darker blue patterns were

sprayed freehand. After drying, I again removed some overspray inaccuracies

with the lighter colour.

Also the anti-glare area at the nose

was sprayed mat black and the metal area at the exhaust and stabilizer

were sprayed metallic, using variuous paints like Gunze 8 metal. (The tri-angle

stickers are not required for this scheme E).

.

.

.

I than tried to replicate various patterns on panels and panellines with slightly lighter tints of the same colours. This is quite some work but makes the model really interesting as on the real planes various colour differences are seen:

.

.

this metal area needs some extra shades...

.

.

Also all the various bits like undercarriage doors, fuel tanks and so one were sprayed as well.

and fuel tanks and pylons

.

.

and detail of the canopy frame (with

some Eduard details)

with the cockpit masking tape removed

after some years....

Next step is now adding some subtle panel lines details, using Promodeller wash. This will be followed by some gloss coats of Johnson Future and adding the stencils and main decals.

On to next [ page 3 ...]

(c) Copyright "designer"/ All rights reserved. Your comments are welcomed by webmaster

Created this page July 10, 2007