Meindert de Vreeze

Professional Career Aircraft Projects

First job got into was as an aeronautical engineer at "a" famous Dutch Fokker Aircraft manufacturer. The role was "conceptual aircraft designer", sometimes also called advanced design and at the company also preliminary design. The small department was called "Voorontwerp Afdeling" within Engineering. Many Fokker employees did not even know of its existence.

Competitor studies and projects on details of real flying aircraft were done, that's quite something! One of my first assignments was analysing the Dornier 328 Jet that was competing with the Fokker 50. My findings were used in the Sales department to persuade customers to buy Fokker 50 propliners in stead.

After years of learning, the first preliminary designs were made within the conceptual aircraft design project team (see below). At that time my manager and superb chief Fokker aircraft designer Evert used the ideas for "sparring" and further thoughts.

The starting point for new aircraft development are usually understanding requirements from the future market, in this case of airlines. The first aircraft concepts are than to meet or exceed these market requirements, taking new technologies into account. It is also important to look at developments at competitors e.g. to beat the competition. Development budgets are important here and making good estimates of airline operating costs of the new aircraft design.

In parallel to designing and "sparring" I also got the task to develop extensive methods for conceptual aircraft design. Particularly for very advanced aerodynamics at this conceptual design stage. Design methods evolved up till the stage that rapid sensitivity studies on various designs could be performed. Methods were not only based on empirical but using Fokker's own methods developed that were based on hundreds on windtunnel test data and industry data. And data analysis of competitors.

All power was combined using the mainframe VAX computer with hundreds of modules in an ADA based language programmed computer EVAERO program. It was constructed and programmed over 5 years with thousands of formulas to evolve into EVAERO calculations program. It had more than 125,000 source code lines in ADA.

(In the methods also "future design capability" technology factors were incorporated for possible advanced aerodynamics at cricital points in the design such as advanced airfoils and low drag technologies. But Fokker designs for the near future did not use these).

With the program it was possible with up to 5% accuracy to calculate the aerodynamics including low speed aerodynamics of any actual real aircraft of typical passenger airliner configuration. Without CFD! The accuracy was so good that complex CFD calculations and windtunnel results could be verified as well for different Reynolds numbers. And that looks more simple than it is!

So the program could not only be used for our own Fokker designs but also to analyse competitor aircraft in development as well, and combined with performance programs their competing potential.

Projects, projects, which ones?

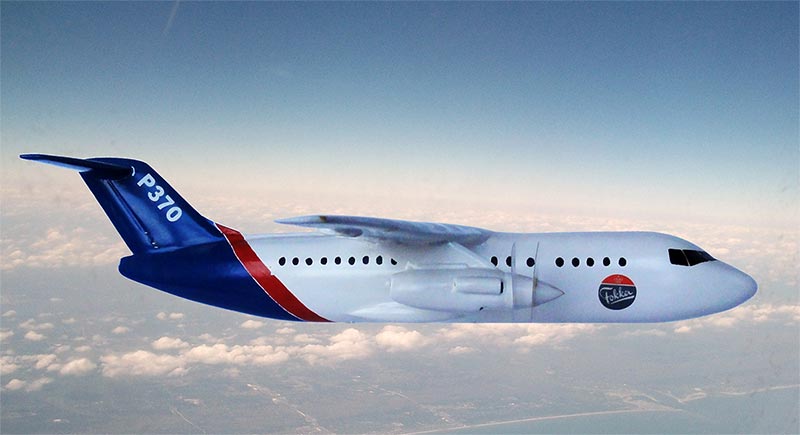

"P370" was a high Mach number regional airliner (Mach 0.72) family with 80-105 passengers. Advanced propulsion consisted of two "free turbine" engines with counter rotating props with swept composite blades. Engine configuration was checked with partner Rolls Royce, the well known engine manufacturer. Fokker chief designer Evert was the "man behind this concept".

The aircraft in the 80 seat variant was only slightly longer than 27 meters! It had an oval shaped fuselage cross section, optimized for optimal volume distribution and low undercarriage for quick loading at the cargo bay area. Modern materials were envisaged, but it was conventional when there were no costs advantages to be obtained. Control system was conventional as FBW had no extra benefits.

Design showed that a relatively cheap aircraft with up to 20% lower DOC but superior jet like performance was well possible using advanced techniques in well chosen areas.

Here photos of the balsa wood 1/72 model I made of this project and a CAD layout. The model was used during internal company Board presentations.

one of the first

CAD models (CADAM system)

one of the first

CAD models (CADAM system) The Fokker aircraft company meanwhile was in big trouble due to lack of sales and the airline industry crisis from 1990. DASA took over a 51% stake and got a big say in the company projects, we had to drop this project. DASA wanted a more "A320 a like aircraft". Fokker Project of 1991 was dropped and this "secret" project never got any publicity.

"P2" was a 95-130 seat airliner family (Mach 0.78) with several variants being studied. This project was started after a DASA proposal for a "A320 a like" studied around 1993 was unrealistic. The Fokker design team came back with their own new designs with a T-tail design. One variant shown here is an version without slats but very high aspect ratio wing (AR = 12). It had an advanced wing that offered same performance as many conventional slatted aircraft in existence today. Fokker's own advanced airfoils were used. Careful balance was made on desired high speed (low Mach dragrise and low induced drag) ande low speed (high CLmax). Full Reynolds effects were estimated including effects on local peak pressure in both high and low speeds. The L/D ratio was extremely well without using any new technology surface roughness manufacturer techniques.

Cabin configuration was aimed at both comfortable layouts for passengers as well as low cost loading and fast turn around times for the airline.

Aimed at delivering a low cost aircraft with DOC targets up to 15% lower than any competitor at that time, it proved to be to good to be believed!

Projects P1 and P2 took over 6 up to 14 months and some designs were checked in windtunnel testing. Test results were very promising. This Fokker Project of 1993-1995 was given some publicity.

Here a photo of the small balsa wood 1/72 scale model I made of this project. It was also shown at the Le Bourget Air Show at the Sales area / Fokker booth in the early nineties.

Unfortunately the Fokker Aircraft company with DASA involvement went bankrupt in 1995 / 1996. The Dutch Government did not provide any additional funding. Full Design capability was discarded at Fokker and I lost my job with many colleagues. The Fokker company soldiered on in a minimal size on for maintaining existing Airline Fleets.

I had to completely change my future career.

Back to aircraft design...

last update this page March, 2022, (c) Copyright Meindert "designer"